Abstract

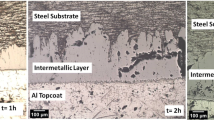

This study deals with a facile strategy to coat the surface of reduced activation ferritic/martensitic steel (RAFMS) substrate with alumina and aluminide layer. The coating on the surface of the substrate was obtained by using hot dip aluminization technique followed by heat treatment. The thickness, phases, and composition of the coating were analyzed using optical microscopy, XRD, and scanning electron microscopy–EDS studies. Optical microscopy images of the dipped sample revealed the presence of two distinguished layers: an outer thick layer (thickness about 32 µm) and an inner thin layer (thickness about 18 µm). Similarly, optical microscopy images of heat-treated samples indicated the presence of two layers but with increased thickness: outer layer (thickness about 120 µm) and inner layer (thickness about 80 µm). The XRD pattern of dipped sample revealed the presence of Al and Si on the surface of the coating while that of heat-treated sample indicated the presence of Fe2Al5, α-Al2O3, and θ-Al2O3. Scanning electron microscopy–EDS studies revealed the presence of three distinct layers in dipped samples: outer layer consisting of Al and Si having thickness 33 µm, middle finger-like layer having thickness 12 µm and inner layer having thickness of 6 µm. Likewise, for heat-treated sample, three layers were observed but with increased thickness.

Similar content being viewed by others

References

E.R. Kumar, C. Danani, I. Sandeep, C. Chakrapani, N.R. Pragash, V. Chaudhari, C. Rotti, P.M. Raole, J. Alphonsa, S.P. Deshpande, Preliminary design of Indian Test Blanket Module for ITER. Fusion Eng. Des. 83, 1169–1172 (2008)

B. Paul, K. Raju, M. Vadsola, T.S.R.C. Murthy, J. Kishor, P. Arora, P. Chak, K. Singh, S. Majumdar, V. Kain, Investigations on wear and liquid metal corrosion behaviour of aluminized IN-RAFMS. Fusion Eng. Des. 128, 204–214 (2018)

S. Majumdar, B. Paul, P. Chakraborty, J. Kishor, V. Kain, G.K. Dey, Formation of Al2O3/FeAl coatings on a 9Cr-1Mo steel, and corrosion evaluation in flowing Pb-17Li loop. J. Nuclear Mater. 486, 60–65 (2017)

C.J. Wang, C.C. Li, Corrosion behaviors of AISI 1025 steels with electroless nickel/aluminized coatings in NaCl-induced hot corrosion. Surf. Coat. Technol. 177–178, 37–43 (2004)

G. Eggeler, W. Auer, H. Kaesche, On the influence of silicon on the growth of the alloy layer during hot dip aluminizing. J. Mater. Sci. 21, 3348–3350 (1986)

S. Han, H. Li, S. Wang, L. Jiang, X. Liu, Influence of silicon on hot-dip aluminizing process and subsequent oxidation for preparing hydrogen/tritium permeation barriers. Int. J. Hydrogen Energy 35, 2689–2693 (2010)

K. Bouche, F. Barbier, A. Coulet, Intermetallic compound layer growth between solid iron and molten aluminium. Mater. Sci. Eng. A 249, 167–175 (1998)

J. An, Y.B. Liu, M.Z. Zhang, B. Yang, Effect of Si on the interfacial bonding strength of Al-Pb alloy strips and hot-dip aluminized steel sheets by hot rolling. J. Mater. Process. Technol. 120, 30–36 (2002)

K. Singh, S. Gite, B. Ashlesha, K.B. Devi, Hot dip aluminizing and heat treatment of RAFMS. Chem. Sci. Rev. Lett. 4, 860–869 (2015)

H. Glasbrenner, J. Konys, Investigation on hot-dip aluminised and subsequent HIP’ped steel sheets. Fusion Eng. Des. 58–59, 725–729 (2001)

P. Song, X. Yu, T. Huang, X. He, Q. Ji, J. Zang, R. Chen, J. Lii, J. Lu, Evolution of in situ pores and high-temperature thermal-barrier performance of Al-Si coating on NiCoCrAl alloy. Surf. Coat. Technol. 344, 489–498 (2018)

W.-J. Cheng, C.-J. Wang, Growth of intermetallic layer in the aluminide mild steel during hot-dipping. Surf. Coat. Technol. 204, 824–828 (2009)

Y.-Y. Chang, C.-C. Tsaur, J.C. Rock, Microstructure studies of an aluminide coating on 9Cr-1Mo steel during high temperature oxidation. Surf. Coat. Technol. 200, 6588–6593 (2006)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaur, J., Singh, K., Paul, B. et al. Development of Coating on the Surface of Reduced Activation Ferritic Martensitic Steel (RAFMS) Substrate Using Hot Dip Aluminization and Heat Treatment. Metallogr. Microstruct. Anal. 8, 118–122 (2019). https://doi.org/10.1007/s13632-018-0509-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0509-3