Abstract

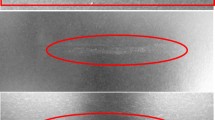

The characteristics of a hook-like microstructure in an ultra-low carbon (ULC) steel continuous casting slab under different casting conditions were investigated via metallographic experiments. The results revealed that the hook depth decreased with increasing pouring temperature and casting speed. Bikerman’s equations and the iron-carbon phase diagram were used to explain the hook formation mechanism. In addition, evolution of the hook microstructure during the initial solidification process of the ULC steel slab under different casting conditions was evaluated through numerical modeling. For the hook-less shell, the present model yielded a thickness that corresponds closely to the value obtained from traditional models, but the calculated inner shapes of the shells differed significantly. The calculated shape of the hook-containing shell was validated by metallographic observations of a common slab and a breakout shell. The simulation results showed that at a given “bury point,” the hook depth is equal to the shell thickness. Moreover, the distance from the bury point to the meniscus increased with increasing casting speed, whereas the distance between the bury point and the slab surface decreased. The distances from the bury point to the meniscus and the slab surface both decreased with increasing casting temperature.

Similar content being viewed by others

References

M. Hanao, M. Kawamoto, A. Yamanaka, Growth of solidified shell just below the meniscus in continuous casting mold. ISIJ Int. 49, 365 (2009)

T. Emi, Influence of physical and chemical properties of mold powders on the solidification and occurrence of surface defects of strand cast slabs. Steelmak. Proc. 61, 350 (1978)

H. Tomono, W. Kurz, W. Heinemann, The liquid steel meniscus in molds and its relevance to the surface quality of castings. Metall. Trans. B 12(2), 409 (1981)

H. Fredriksson, J. Elfsberg, Thoughts about the initial solidification process during continuous casting of steel. Scand. J. Metall. 31(5), 292 (2002)

J. Sengupta, B.G. Thomas, H.J. Shin et al., Mechanism of hook formation in ultralow-carbon steel based on microscopy analysis and thermal-stress modeling. Iron Steel Technol. 4(7), 83 (2007)

J. Sengupta, H.J. Shin, B.G. Thomas et al., Micrograph evidence of meniscus solidification and sub-surface microstructure evolution in continuous-cast ultralow-carbon steels. Acta Mater. 54(4), 1165 (2006)

E. Takeuchi, J.K. Brimacombe, Effect of oscillation-mark formation on the surface quality of continuously cast steel slabs. Metall. Trans. B 16(3), 605 (1985)

H. Yasunaka, R. Yamanaka, T. Inoue et al., Pinhole and inclusion defects formed at the subsurface in ultra low carbon steel. Tetsu-to-Hagane 81(5), 529 (2009)

P.E.R. Lopez, K.C. Mills, P.D. Lee et al., A unified mechanism for the formation of oscillation marks. Metall. Mater. Trans. B 43(1), 109–122 (2012)

M. Vynnycky, S. Saleem, K.M. Devine et al., On the formation of fold-type oscillation marks in the continuous casting of steel. R Soc Open Sci. 6, 170062 (2017)

J.J. Bikerman, Physical Surfaces (Academic Press, London, 1970)

J.X. Song, Z.Z. Cai et al., Heat transfer and deformation behavior of shell solidification in wide and thick slab continuous casting mold. J. Iron Steel Res. 21(S1), 1 (2014)

C. Pfeiler, B.G. Thomas, M. Wu et al., Solidification and particle entrapment during continuous casting of steel. Steel Res. Int. 79(8), 599 (2008)

Acknowledgements

The authors wish to express their appreciation to the National Natural Science Foundation of China (Grant No. 51574106), the Hebei Provincial Natural Science Foundation of China (E2016209396), the Hebei Provincial Natural Science Foundation of China (E2017209223), and the High-Level Talents Research Project of Hebei (GCC2014030) for providing the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xiao, P., Zhu, L., Liu, Z. et al. Hook-Like Microstructure at the Subsurface of Ultra-low Carbon Steel Slab. Metallogr. Microstruct. Anal. 7, 414–420 (2018). https://doi.org/10.1007/s13632-018-0457-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0457-y