Abstract

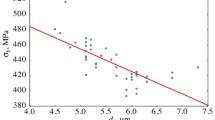

A novel low-carbon micro-alloyed steel has been developed with ultrahigh strength (UTS ~ 1700 MPa), satisfactory ductility (total elongation ~ 13%) and impact toughness (25 J/cm2 at − 40 °C) for light-weight applications in automobile, aerospace and defence sectors. The effect of finish rolling temperatures (850–750 °C) and cooling rate (air cooling versus water quenching) on the evolution of microstructure and crystallographic texture and finally on the mechanical properties of thermo-mechanically controlled processed steel has been studied. A refinement in mixed microstructure comprised of granular/lower bainite and lath/plate martensite and an intensification of Goss and rotated Goss texture components were found with the decrease in finish rolling temperature and increase in cooling rate. Interaction of fine-scale carbide/carbonitride precipitates of Nb and Ti with the dislocation substructure present within bainite and martensite contributed significant precipitation strengthening to the steel.

Similar content being viewed by others

References

K. Zhang, M. Zhang, Z. Guo, N. Chen, Y. Rong, A new effect of retained austenite on ductility enhancement in high-strength quenching–partitioning–tempering martensitic steel. Mater. Sci. Eng. A 528, 8486–8491 (2011)

H.K.D.H. Bhadeshia, R. Honeycombe, Steels: Microstructure and Properties, 3rd edn. (Elsevier, Amsterdam, 2006)

T. Gladman, The Physical Metallurgy of Microalloyed Steels (Institute of Materials, London, 1997)

M. De Meyer, D. Vanderschueren, B.C. De Cooman, The influence of the substitution of Si by Al on the properties of cold rolled C–Mn–Si TRIP steels. ISIJ Int. 39(8), 813–822 (1999)

K.I. Sugimoto, M. Kobayashi, S.I. Hashimoto, Ductility and strain-induced transformation in a high-strength transformation-induced plasticity-aided dual-phase steel. Metall. Trans. A 23(11), 3085–3091 (1992)

T.V. Philip, T.J. McCaffy, Ultrahigh Strength Steel, Metals Handbook, 10th edn. (ASM International, New York, 1990), pp. 431–448

R. Kuziak, R. Kawalla, S. Waengler, Advanced high strength steels for automotive industry. Arch. Civ. Mech. Eng. 8(2), 103–117 (2008)

D. K. Matlock, J. G. Speer, Third generation of AHSS: microstructure design concepts, in Microstructure and Texture in Steels (Springer, London, 2009), pp. 185–205

M. Zhao, K. Yang, Y. Shan, The effects of thermo-mechanical control process on microstructures and mechanical properties of a commercial pipeline steel. Mater. Sci. Eng. A 335, 14–20 (2002)

S. Mandal, N.K. Tewary, S.K. Ghosh, D. Chakrabarti, S. Chatterjee, Thermo-mechanically controlled processed ultrahigh strength steel: microstructure, texture and mechanical properties. Mater. Sci. Eng. A 663, 126–140 (2016)

G. Mandal, C. Roy, S.K. Ghosh, S. Chatterjee, Structure-property relationship in a 2 GPa grade micro-alloyed ultrahigh strength steel. J. Alloys Compd. 705, 817–827 (2017)

M.C. Zhao, Y.Y. Shan, J.B. Qu, F.R. Xiao, Y. Zhong, K. Yang, Acicular ferrite formation in a pipeline steel with thermo-mechanical control process. Acta Metall. Sin. 37(8), 820–824 (2001)

G.J. Baczynski, J.J. Jonas, L.E. Collins, The influence of rolling practice on notch toughness and texture development in high-strength line pipe. Metall. Mater. Trans. A 30, 3045–3054 (1999)

B. Faucher, B. Dogan, Evaluation of the fracture toughness of hot-rolled low-alloy Ti–V plate steel. Metall. Trans. A 19, 505–516 (1988)

J.R. Davis, Alloying: Understanding the Basics, ASM International, Materials Park, Ohio-44073-0002, 193-209(2001)

M. Calcagnotto, D. Ponge, D. Raabe, On the effect of manganese on grain size stability and hardenability in ultrafine-grained ferrite/martensite dual-phase steels. Metall. Mater. Trans. A 43, 37–46 (2012)

J.A. Omotoyinbo, O.O. Oluwole, Effect of thermomechanical working on the strengthening of some austenitic steel grades. Mater. Des. 30, 335–339 (2009)

S. Zhang, P. Wang, D. Li, Y. Li, Investigation of the evolution of retained austenite in Fe–13%Cr–4%Ni martensitic stainless steel during intercritical tempering. Mater. Des. 84, 385–394 (2015)

J. Kong, C. Xie, Effect of molybdenum on continuous cooling bainite transformation of low-carbon microalloyed steel. Mater. Des. 27, 1169–1173 (2006)

R.D.K. Misra, H. Nathani, J.E. Hartmann, F. Siciliano, Microstructural evolution in a new 770 MPa hot rolled Nb–Ti microalloyed steel. Mater. Sci. Eng. A 394, 339–352 (2005)

X. Wang, H. Zhao, C. Shang, X. He, The microstructure and properties of high performance steels with low yield-to-tensile ratio. J. Alloys Compd. 577S, S678–S683 (2013)

K. Nishioka, K. Ichikawa, Progress in thermomechanical control of steel plates and their commercialization. Sci. Technol. Adv. Mater. 13, 1–20 (2012)

P.S. Bandyopadhyay, S.K. Ghosh, S. Kundu, S. Chatterjee, Evolution of microstructure and mechanical properties of thermomechanically processed ultrahigh-strength steel. Metall. Mater. Trans. A 42, 2742–2752 (2011)

F. Fletcher, Meta-analysis of T NR measurements: determining new empirical models based on composition and strain, in: Austenite Processing Symposium (Internal Company Presentation, 2008), pp. 1–14

C. Ma, L. Hou, J. Zhang, L. Zhuang, Influence of thickness reduction per pass on strain, microstructures and mechanical properties of 7050 Al alloy sheet processed by asymmetric rolling. Mater. Sci. Eng. A 650, 454–468 (2016)

I. Tamura, H. Sekine, T. Tanaka and C. Ouchi: Thermomechanical Processing of High-strength Low-alloy Steels, Butterworth & Co. Ltd., 39–91(1988)

ASTM Standard E8 M-96, Standard test methods for tension testing of metallic materials, Annual Book of ASTM Standards, 03.01, 76–96(1996)

N. Tsuji, R. Ueji, Y. Minamino, Y. Saito, A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property. Scr. Mater. 46(4), 305–310 (2002)

Chen Jun, Tang Shuai, Liu Zhen-Yu, Wang Guo-Dong, Microstructural characteristics with various cooling paths and the mechanism of embrittlement and toughening in low-carbon high performance bridge steel. Mater. Sci. Eng. A 559, 241–249 (2013)

Q. Sylvain, M. Ghiath, D. Benoit, Orowan strengthening and forest hardening superposition examined by dislocation dynamics simulations. Acta Mater. 58, 5586–5595 (2010)

B. Verlinden, J. Driver, I. Samajdar, R.D. Doherty, Thermo-Mechanical Processing of Metallic Materials, 1st edn. (Elsevier Pub., Amsterdam, 2007), pp. 417–424

H. Wu, B. Ju, D. Tang, R. Hua, A. Guo, Q. Kang, D. Wang, Effect of Nb addition on the microstructure and mechanical properties of an 1800 MPa ultrahigh strength steel. Mater. Sci. Eng. A 622, 61–66 (2015)

I.A. Yakubtsov, P. Poruks, J.D. Boyd, Microstructure and mechanical properties of bainitic low carbon high strength plate steels. Mater. Sci. Eng. A 480, 109–116 (2008)

R.K. Ray, J.J. Jonas, Transformation textures in steels. Int. Mater. Rev. 35(1), 1–36 (1990)

K. Zhu, O. Bouaziz, C. Oberbillig, M. Huang, An approach to define the effective lath size controlling yield strength of bainite. Mater. Sci. Eng. A 527, 6614–6619 (2010)

S. Chen, Y.G. An, C. Lahaije, Toughness improvement in hot rolled HSLA steel plates through asymmetric rolling. Mater. Sci. Eng. A 625, 374–379 (2015)

Y. You, C. Shang, N. Wenjin, S. Subramanian, Investigation on the microstructure and toughness of coarse grained heat affected zone in X-100 multi-phase pipeline steel with high Nb content. Mater. Sci. Eng. A 558, 692–701 (2012)

A.J. Kaijalainen, P. Suikkanen, L. Pentti Karjalainen, J.J. Jonas, Effect of austenite pancaking on the microstructure, texture, and bendability of an ultrahigh-strength strip steel. Metal. Mater. Trans. A 45, 1273–1283 (2014)

B.C. De Cooman, Structure-properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 8, 285–303 (2004)

J. Jin, Y. Lee, Strain hardening behavior of a Fe–18Mn–0.6C–1.5Al TWIP steel. Mater. Sci. Eng. A 527, 157–161 (2009)

H. Rastegari, A. Kermanpur, A. Najafizadeh, Effect of initial microstructure on the work hardening behavior of plain eutectoid steel. Mater. Sci. Eng. A 632, 103–109 (2015)

S. Zhu, Y.L. Kang, K.K. Ren, S.C. Li, Effect of partitioning temperature on work hardening behavior of Q&P steels. Adv. Mater. Res. 299–300, 403–407 (2011)

A.K. De, J.G. Speer, D.K. Matlock, D.C. Murdock, M.C. Mataya, R.J. Comstock Jr., Deformation-induced phase transformation and strain hardening in type 304 austenitic stainless steel. Metall. Mater. Trans. A 37(6), 1875–1886 (2006)

T.S. Byun, I.S. Kim, Tensile properties and inhomogeneous deformation of ferrite-martensite dual-phase steels. J. Mater. Sci. 28(11), 2923–2932 (1993)

F. Ozturk, A. Polat, S. Toros, R.C. Picu, Strain hardening and strain rate sensitivity behaviors of advanced high strength steels. J. Iron. Steel Res. Int. 20(6), 68–74 (2013)

P. Wang, S.P. Lu, N.M. Xiao, D.Z. Li, Y.Y. Li, Effect of delta ferrite on impact properties of low carbon 13Cr–4Ni martensitic stainless steel. Mater. Sci. Eng. A 527, 3210–3216 (2010)

Y.-L. Kang, Q.-H. Han, X.-M. Zhao, M.-H. Cai, Influence of nanoparticle reinforcements on the strengthening mechanisms of an ultrafine-grained dual phase steel containing titanium. Mater. Des. 44, 331–339 (2013)

X.P. Mao, X.D. Huo, X.J. Sun, Y.Z. Chai, Strengthening mechanisms of a new 700 MPa hot rolled Ti-microalloyed steel produced by compact strip production. J. Mater. Process. Technol. 210, 1660–1666 (2010)

Y. Mazaheri, A. Kermanpur, A. Najafizadeh, Strengthening mechanisms of ultrafine grained dual phase steels developed by new thermomechanical processing. ISIJ Int. 55, 218–226 (2015)

J.E. Bailey, P.B. Hirsch, The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver. Phil. Mag. 5, 485–497 (1960)

M. Calcagnotto, D. Ponge, E. Demir, D. Raabe, Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 527, 2738–2746 (2010)

S.S. Campos, E.V. Morales, H.J. Kestenbach, On strengthening mechanisms in commercial Nb–Ti hot strip steels. Metall. Mater. Trans. A 32A, 1245–1248 (2001)

I. Kozasu, C. Ouchi, T. Sampei, T. Okita, Microalloying ‘75 (Union Carbide Corp., New York, 1976), pp. 120–135

Y. Funakawa, T. Shiozaki, K. Tomita, T. Yamamoto, E. Maeda, Development of high strength hot-rolled sheet steel consisting of ferrite and nanometer-sized carbides. ISIJ Int. 44, 1945–1951 (2004)

J. Hu, L. Du, J. Wang, Effect of cooling procedure on microstructures and mechanical properties of hot rolled Nb–Ti bainitic high strength steel. Mater. Sci. Eng. A 554, 79–85 (2012)

H. Xie, L. Du, J. Hu, R.D.K. Misra, Microstructure and mechanical properties of a novel 1000 MPa grade TMCP low carbon microalloyed steel with combination of high strength and excellent toughness. Mater. Sci. Eng. A 612, 123–130 (2014)

X. Li, C. Lei, X. Deng, Z. Wang, Y. Yu, G. Wang, R.D.K. Misra, Precipitation strengthening in titanium microalloyed high-strength steel plates with new generation-thermomechanical controlled processing (NG-TMCP). J. Alloys Compd. 689, 542–553 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mandal, G., Ghosh, S.K., Chakrabarti, D. et al. Effects of Thermo-mechanical Process Parameters on Microstructure and Crystallographic Texture of High Ni–Mo Ultrahigh Strength Steel. Metallogr. Microstruct. Anal. 7, 222–238 (2018). https://doi.org/10.1007/s13632-018-0432-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-018-0432-7