Abstract

Key message

Segregating stands and logs based on internal wood properties is likely to lead to improvements in value for forest and mill owners, but some situations were found where no segregation was the best alternative. Where segregation was the best alternative, segregating logs at the landing, or stands based on pre-harvest inventory assessments, led to the greatest value improvements.

Context

The benefits of segregating stands, stems and logs based on wood properties are not clear due to the high variability of wood properties, poor market signals for wood with superior properties and poor understanding of the costs across the value chain.

Aims

The aim of this study was to determine if the benefits of segregating stands and logs outweighed the additional costs.

Methods

A techno-economic model (SEGMOD) was constructed that allowed comparisons of segregation at different approaches in the supply chain. The model was populated with Pinus radiata (D.Don) stand, cost and price data from companies operating in four forestry regions of New Zealand. A total of 255 segregation scenarios were modelled, which included variations in segregation approach, stand type, stand location, terrain type, market focus and market horizon.

Results

Segregating logs based on internal wood properties led to improvements in stumpage and mill door value for most of the scenario sets evaluated. The No Segregation option was found (infrequently) to be best in unpruned stands. Segregating logs based on pre-harvest inventory assessments or at the landing would appear to be the best approach.

Conclusion

The economic benefits of segregating stands and logs for forest and mill owners outweighed the additional costs in most of the scenarios evaluated.

Similar content being viewed by others

1 Introduction

For the forestry value chain to operate efficiently and profitably, wood processors need to obtain the wood raw material resource best suited to their needs (Murphy et al. 2010). Processing operations differ in their wood raw material requirements depending on the product that they are making (Moore and Cown 2015). Mills making structural products such as dimension lumber, glue-laminated lumber and laminated veneer lumber generally require logs that will give high yields of products with acceptable stiffness and low warp (Perstorper et al. 1995). For mills making appearance grade products, the key requirements are dimensional stability and the absence of defects such as dead knots, resin features and internal checks (Moore and Cown 2015). In the future, an increasing proportion of the wood supply to mills will come from intensively managed forests (Gardiner and Moore 2014). The productivity improvements that have resulted from these intensive management practices have generally led to substantial reductions in rotation age (e.g. Fox et al. 2007), which in turn has resulted in trees and logs with much higher proportions of corewood (juvenile wood) (Moore and Cown 2017). In softwood species, in particular, corewood has a negative impact on the performance of most wood products (Moore and Cown 2017; Zobel and Sprague 1998). Therefore, for the forestry value chain to operate successfully, forest growers need to identify and segregate stands and logs on the basis of log and wood properties (Manley 2002).

Historically, trees have been converted into logs and these logs sorted on the basis of external attributes such as diameter, length, straightness, branch size and the presence of obvious defects such as end checks, decay and resin bleeding. While these attributes affect the yields of products that can be obtained by a mill, they have little impact on end-product performance which is mostly driven by the internal wood properties of logs. There are a number of challenges to segregation based on internal wood properties. The first is that there are many log and wood properties of interest to wood processors, and the second is that there is also high variability in important wood properties within and among growing regions as well as within and among individual stems in a stand. Despite these challenges, a number of tools and techniques have been developed to help forest growers and wood processors assess this variability and segregate stands on the basis of wood quality attributes. These include portable acoustic tools that provide an estimate of wood stiffness (Wang et al. 2007), measurements of outerwood density on core samples taken from the trees or indirectly on standing trees using tools such as the Pilodyn (Cown 1978) and protocols for assessing resinous defects (McConchie 2003).

While many tools and techniques are available for segregating wood based on internal properties, in their review of recent studies on segregation technologies, Murphy and Cown (2015) reported that few have been implemented commercially and that some are better suited for application in mills than in forests. Furthermore, this review concluded that the benefits of segregating stands, stems and logs based on wood properties are not clear due to the high variability of wood properties, poor market signals (in terms of price) for wood with superior properties and poor understanding of the costs across the value chain. Where models have been developed to investigate the economics of segregation, they tend to look at this from the perspective of a single participant in the value chain, e.g. a laminated veneer lumber mill (Amishev and Murphy 2009) or a central processing yard (CPY) (Bilek 2009). Only a few models look across the value chain and these have limitations often poorly representing some participants in the value chain.

This manuscript describes the structure of a model, SEGMOD, which can be used to determine the economics of segregating wood at various points in the standing tree to mill exit-door value chain based on internal wood properties. It also describes the application of SEGMOD to four case studies in different forest regions within New Zealand and the conclusions drawn therefrom. In these case studies, the null hypothesis is that the economic benefits of segregating Pinus radiata (D.Don) stands and logs based on internal wood properties will exceed the costs for both forest owners and mill owners.

2 Methods and materials

2.1 Model description

SEGMOD is similar in structure to the TREEVAL model developed by Briggs (1989) but includes the ability to optimally segregate logs based on internal wood properties. It calculates “stumpage” and mill door return-to-log (RTL) values per hectare based on user-selected wood properties, segregation approaches and terrain conditions. Five different segregation approaches can be evaluated: (1) no segregation (NoSeg), (2) segregation in the forest based on pre-harvest inventory data (PHISeg), (3) segregation at the landing (LandSeg), (4) segregation at a centralised processing yard (CPYSeg) and (5) segregation in a mill (MillSeg). Under a no segregation approach, segregation is only based on size and external quality features and the optimal bucking routine will ignore internal wood properties. If segregation is based on size and external characteristics plus internal quality, then the user can segregate appearance grade logs based on the amount of clear wood (as quantified by the Pruned Log Index; Park (1989)) and/or resin score (McConchie 2003) and for structural grade logs based on acoustic velocity and/or density. SEGMOD is able to accommodate four different end-products: (1) appearance lumber, (2) structural lumber, (3) medium density fibreboard (MDF) and (4) export logs. The latter reflects the fact that in the New Zealand context more than half the annual harvest is exported in log form (Forest Owners Association 2017).

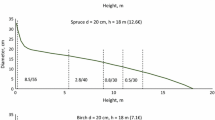

The starting point for the model is user-supplied stand data consisting of descriptions of the external stem characteristics and internal wood properties (density and acoustic velocity) for a representative sample of trees. Tree external descriptions are based on the system of overlapping feature codes developed by Deadman and Goulding (1978). Under this approach, the stem is partitioned in sections of uniform quality based on visual assessment of attributes such as branch size and sweep. The position of other attributes, such as forks, resin features and rot, that affect merchandising decisions are also noted. Internal wood properties information can be provided by the user based on field sampling and the within-tree variation predicted using models (e.g. Kimberley et al. 2015) or predicted from site-specific environmental variables (e.g. Palmer et al. 2013). The two internal wood properties of most interest are density and modulus of elasticity (often approximated through acoustic wave velocity) as these affect the outturn of structural lumber. Values measured (or predicted) at breast height (1.4 m) are then extrapolated to other heights in the stem using non-linear functions that have been developed for wood density (see Eq. (3) and Figure 5 in Kimberley et al. 2015) and acoustic velocity. These stem descriptions are consistent with log specifications, which are provided in terms of minimum and maximum values of small-end diameter, length, acoustic velocity and density. Limits are also specified for maximum branch size, defect core size, internode index and resin score. The number of log grades (sorts) can be varied by the segregation approach. It is typically greatest for the landing and CPY segregation approaches and lowest for the no-segregation approach. This reflects the different amounts of information, particularly on internal wood properties, that can be gathered at different segregation points, which enables trees to be merchandised into a larger number of log sorts each with a tighter range of values for internal wood properties. These descriptions enable stems to be optimally bucked and both mill-door return-to-log values (RTL) and log grade recovery from stands to be calculated.

To calculate the costs of segregation, information is required on the following: (1) mill log handling, additional log sorting, and log processing costs for an appearance grade mill, a structural grade mill, and an MDF mill; (2) CPY costs, including additional wood-properties based log sorting costs at the yard and (3) pre-harvest inventory costs for non-sorting and sorting options at the stand level. Harvesting and transport costs are also required to enable a “stumpage” return to be calculated. Harvesting costs are terrain dependent (i.e. flat vs. steep) and also vary depending on whether or not a CPY is included in the landing to mill supply chain. Two types of adjustments are made to these costs; one based on the number of log sorts, and one based on the type of sorting undertaken on the landing. Based on research by Tolan and Visser (2015) and Cass et al. (2009), harvesting costs are adjusted up or down by 1.5% for each log sort above or below 15. Harvesting costs are also adjusted by 2.5 and 2.0%, respectively, for wood properties-based sorting on “not steep” and “steep” terrain, respectively. Transport costs are given on a per tonne basis. Two sets of transport costs, with associated one-way transport distances, are required so that a distance-based transport cost function can be developed. Distances direct from the stand of interest to an appearance grade mill, a structural grade mill, an MDF mill and an export port need to be provided by the user. If a CPY is included in the supply chain, distances are entered from the stand to the CPY and from the CPY to the mills and/or port.

SEGMOD first calculates a mill door RTL value ($ per m3) for each log type included in the log specification file (see the “Mill door RTL value calculations” section and Fig. 1). These RTL calculations are based on prices for lumber (appearance and structural grades), MDF, chip, hogfuel and export logs provided by the user. The relevant mill yard, transport, CPY, harvesting and inventory costs are subtracted to derive “stumpage” RTL values for each log type. If a negative “stumpage” RTL is calculated, usually for a fibre grade log, it is increased to a minimum of $1 per cubic metre; otherwise, potential fibre would be left on the cutover as waste.

Logs are then optimally allocated to appearance grade, structural grade, fibre and export log markets for each stem using optimal bucking routines with the objective of maximising total “stumpage” RTL value per hectare for unconstrained log supply markets. The optimal bucking routines use a dynamic programming (DP) method similar to those originally described by Pnevmaticos and Mann (1972) and first implemented in New Zealand by Deadman and Goulding (1978). The stem, up to the first breakpoint, is divided into fixed length intervals of one decimetre for each of which the external and internal quality features are assigned and the volume and end diameters are estimated using taper equations. DP works by moving from one trivial solution to another for the whole piece in an inductive manner. Given the optimal result for each of the n-1 intervals, the sum of the value at the nth interval after cutting a log of length m intervals plus the value of the optimal result for the first n-m intervals can be calculated for all feasible log types. Infeasible log types do not meet external quality (e.g. branch size), internal quality (e.g. average acoustic velocity) or dimensional (e.g. minimum small end diameter) attributes contained in the stem between interval n and interval n-m. The log type and value of m that gives the maximum value are retained as the optimal combination for the nth interval. On reaching the breakpoint limit, the algorithm scans back through the records to identify the optimal pattern and allocation for the whole stem.

Any adjustments made to “stumpage” RTL values ($ per m3) to convert them from a negative value to $1 per cubic metre are subtracted from the stand level ($ per ha) values. Any log making waste produced also incurs a nominal penalty of $1 per cubic metre which reflects higher forest re-establishment costs.

2.1.1 Mill door RTL value calculations

Mill door RTL values were calculated using the following equation:

Mill Door RTL ($ m−3) = (Total Value of Products − Processing Costs)/Log Volume

where:

-

Total Value of Products = Lumber Value + Chip Value + Hogfuel Value

-

Lumber Value = Volume Conversion Factor × \( \sum \limits_{i=1}^{\mathrm{n}}\mathrm{LumberGrade}{\%}_i\times {\mathrm{LumberPrice}}_i \)

-

Chip Value = (1 − Volume Conversion Factor) × Chip% × Chip Price

-

Hogfuel Value = (1 − Volume Conversion Factor) × Hog% × Hogfuel Price

Volume conversion factors for structural and appearance grade mills were based on radiata pine sawing studies carried out by the New Zealand Forest Research Institute in the 1980s (Cown et al. 1987). Small end diameter, sweep and taper were the key parameters in the equation to determine volume conversion factor. Volume conversion factors used in SEGMOD also include a timber-loss factor (7%). The volume conversion factor for the fibre mill was assumed to be 50.8%. Chip% was assumed to be equivalent to 75% of the non-lumber volume. Hog% was assumed to be 25% of the non-lumber volume.

Radiata pine lumber grade recoveries for the appearance grade mill were based on the original sawn timber recovery and grade recovery models developed for pruned and unpruned logs by Cown et al. (1987) which have been updated using unpublished data from additional sawing studies. These models calculate the recovery of sawn timber and the percentage of this recovered volume in the following grades: #1 Clears, #2 Clears, Cuttings, Factory, #1 Framing, #2 Framing, Box and Board, based on information on small-end diameter, defect core size, maximum branch diameter and the spacing between branch clusters (see example in Fig. 2). The relative market value of these lumber grades is highest for #1 Clears and decreases down to Box grade. Board is a mix of lower value grades. The presence or absence of knots (and other features such as resin pockets), the size of knots and the spacing between knots are key determinants of these lumber grades. Following discussions with industry experts, recoveries for the higher grades were adjusted downwards as model predictions, particularly for the better grades, were considered to be “optimistic” in terms of both yield and the ability to sell these in constrained markets. This adjustment brings mill door RTL values more in line with market reality but still allows distinguishing between logs of higher and lower internal wood properties.

Example showing the predicted grade recoveries from the pruned log models as a function of log small-end diameter for four different defect core sizes (135, 165, 195 and 225 mm) and two different maximum branch sizes (20 and 60 mm). The recovery of knot-free grades (#1 Clears and #2 Clears) is affected by log diameter relative to the size of the knotty core, while the recovery of knotty grades (No1 Framing, No2 Framing and Box) is also affected by maximum branch size

Structural lumber grade recoveries were based on models fitted to data from mill studies undertaken using logs from radiata pine stands in the Central North Island of New Zealand (Wood Quality Initiative Ltd., unpublished data). Acoustic velocity and wood density are key drivers of grade recovery in these models which predict the percentage of recovered volume in each of the New Zealand structural timber grades (Standards New Zealand 1993).

2.2 Case study descriptions

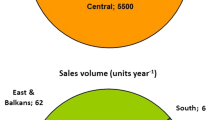

Four different regions within New Zealand were chosen as case study areas (Fig. 3). These regions were chosen because (1) there are appearance, structural and MDF mills plus at least one export port in the region (in the Bay of Plenty region there were also two CPYs), (2) there are a range of stand treatments and wood properties of interest and (3) most importantly there were forest and mill representatives interested and willing to participate in the case studies.

Detailed stem descriptions from standard pre-harvest inventory, along with distances to mills and ports, were provided by forest owners for two representative radiata pine stands in each of the case study regions. Wood density and acoustic velocity information, if available, were provided by the forest owners. Where wood density and acoustic velocity values were not available, they were predicted from national models (Palmer et al. 2013; Kimberley et al. 2015) based on stand location and age. The stem descriptions were converted to a format that could be used in SEGMOD. These descriptions included (a) stem length after breakage, (b) external stem features in the form of branch size, defects and presence of resin and (c) acoustic velocity and wood density. External and internal properties were described in decimetre increments up the stem. Table 1 provides a summary of forest inventory statistics and distances to mills for each stand in the four case study regions.

Information on harvesting, transport, forest inventory and CPY costs was generally provided by the forest grower case study participants. However, such information is commercially sensitive, so while it is used as input into SEGMOD, it is not presented in the paper. Where cost information was not provided by case study participants, regional average values were either obtained from AgriHQ Forestry and Log Price reports (https://agrihq.co.nz/forestry) or from expert opinion. Processing mill participants in the case studies provided indicative ex-mill prices and processing costs for different lumber grades and MDF. Again, this information is commercially sensitive and is not presented in this paper. Where mill owners did not provide prices or processing costs, prices and costs for the same type of mill from another region were used. Prices for export-log grades were obtained from AgriHQ Forestry and Log Price reports.

In New Zealand, the number of log grades (and length combinations) can be very large. To simplify the study, a series of log grades and specifications were developed and applied to all four case studies. Two sets of markets were assumed, one with a primary focus on domestic mills but including some export grades, the other with an “equal” focus on domestic mills and export markets (Table 2). All logs were 6.1 m or less in length.

For each market type, two sets of prices for lumber and export logs were used, the current prices provided by the mill owners and indicative longer-term average prices. The latter were approximately 10% lower for appearance and structural lumber and 10 to 20% lower for export grade logs. The number of log sorts for fibre and export were held constant, within each market type, for differing segregation approaches. The number of, and specifications for, appearance and structural grade logs differed between segregation approaches. The highest number of in-forest sorts was assumed to occur with LandSeg or CPYSeg approaches and the least number with NoSeg. Three structural log classes were defined based on internal wood properties (acoustic velocity and wood density, respectively): low (2.60–3.00 km s−1, 320–360 kg m−3), medium (3.01–3.40 km s−1, 361–410 kg m−3) and high (3.41–3.80 km s−1, 411–460 kg m−3). Three appearance log classes were defined based on resin incidence: clean or light, moderate and severe.

For the NoSeg and MillSeg approaches, it was assumed, for the purpose of determining mill door log prices, that structural logs would fall within the low acoustic velocity (or density) class and appearance logs would fall in the moderate to severe resin classes. For the PHISeg approach, it was assumed that structural logs would fall within medium to low acoustic velocity (or density) classes.

2.3 Scenarios and analyses

A total of 255 scenarios were evaluated using SEGMOD which were a subset of the combination of the following factors for each case study: two stands, two terrain types (steep and “not steep”), two stand locations (location 1 and location 2), two market types (domestic focus and equal domestic/export focus), two price sets (“current” and “longer term” horizons), and five segregation approaches (NoSeg, PHISeg, LandSeg, CPYSeg and MillSeg). Fifteen combinations of stand, terrain type, location, market type and price sets were selected (hereafter referred to as a set of forest and market conditions). For each set of these forest and market conditions, different segregation approaches were tested across each of the case study regions. The CPY segregation approach was only tested in the Bay of Plenty case study, meaning that there were 17 combinations of segregation approach and case study. The subsets allowed comparisons between the main effects. Two sets of measures were used to evaluate the effect of segregation approaches, the overall stumpage value and the combined unadjusted mill-door values.

For each combination of forest and market conditions, the different segregation approaches (NoSeg, PHISeg, LandSeg, CPYSeg and MillSeg) were ranked from 1 to 5 based on stumpage value, where 1 was the approach which yielded the lowest value and 5 was the approach which yielded the highest. Additionally, the percentage difference in stumpage value, relative to the NoSeg approach, was calculated for each combination of conditions. These analyses allow comparison of approaches from the perspective of the forest owner. In addition, the same comparisons were made based on the combined unadjusted “mill door” values. These analyses allow comparison of approaches from the perspective of the “mill” owners. It should be noted that mill door values were the combination of values from the appearance grade mill, structural mill, fibre mill and exporter.

For each case study, overall comparisons were made between segregation approaches. For paired conditions (e.g. holding market type, market horizon and stand location constant but varying terrain type), comparisons were made of terrain type, market type, market horizon, stand type and stand location. Comparisons were deemed to be statistically significantly different if they exceeded tabular values at the alpha = 0.05 level. A range of statistical tests were used including unpaired t tests, paired t tests and Fischer’s LSD multiple range tests. All analyses were undertaken using Statgraphics Plus 5.1 (StatPoint Technologies Inc., VA).

Data availability

The datasets generated and/or analysed during the current study are not publicly available because the data were provided by the case study participants on the proviso that they would not be shared further due to commercial sensitivity reasons.

3 Results

3.1 Stumpage value

3.1.1 Top ranking segregation approaches

Across all case studies and sets of forest and market conditions, PHISeg was the top ranking segregation approach in terms of stumpage return 43% of the time, followed closely by LandSeg (40%) (Table 3). There were instances where MillSeg (10%) and NoSeg (7%) were also the top ranking approaches. CPYSeg was never a top ranked approach. The relative frequency that a particular segregation approach achieved a top ranking differed markedly between case study regions (Table 3). For example, LandSeg was the most common top ranking approach for the Northland case study region but was never the top approach for the Bay of Plenty case study. PHISeg was a dominant or near dominant approach for three of the four case studies, but not for Northland. MillSeg was never the top ranking approach in either the Nelson/Marlborough or Northland case studies but was the second most common top ranking approach for the Bay of Plenty case study. The Bay of Plenty case study was also the only one where NoSeg was the best approach for some of the sets of forest and market conditions evaluated.

Although stand location affected overall stumpage values, it had little effect on which was the top ranked segregation approach, when all other variables were held constant. In only one of 16 paired comparisons (6%) was there a change in the top ranked approach when stand locations were swapped within case study regions, from MillSeg to LandSeg. In unpruned stands, the highest stumpage value occurred when a LandSeg approach was used (Table 4). In pruned stands, the top ranking approaches tended to be PHISeg and LandSeg.

3.1.2 Increase in stumpage values compared with NoSeg

Across all case studies and combinations of forest and market conditions, statistically significant increases in overall stumpage values were found with PHISeg (9.5%), LandSeg (11.8%) and MillSeg (0.9%) approaches (Table 5). PHISeg and LandSeg were not statistically different from each other. CPYSeg was shown to result in lower overall stumpage values compared with NoSeg.

The magnitude of the improvements in stumpage value resulting from the different segregation approaches were not consistent between all case studies (Table 5). The benefits of segregation were greatest in the Northland case study for all approaches and lowest in the Nelson/Marlborough case study. The benefits of segregation in the Bay of Plenty and Southland/Otago case studies tended to be similar to each other and sit between those of the other two case studies.

3.1.3 Sensitivity of stumpage value increases and ranking to key variables

Neither terrain type (steep vs. not steep) nor stand type (pruned vs. unpruned) had any statistically significant effect on the increase in stumpage value for any of the segregation approaches when paired subsets were compared (Table 6). Market type did affect the level of increase for the segregation approaches, but not always in the same manner. When the focus was on domestic markets, the increase was significantly lower for the PHISeg and LandSeg approaches than for an equal focus on domestic and export markets. The reverse was found for the MillSeg approach, i.e. the level of increase was significantly higher for the domestic market focus than for the “equal” domestic and export market focus. The market horizon also affected the level of increase for two of the approaches—PHISeg and LandSeg—with the increase being greater for a longer-term market horizon.

3.2 Mill door value

For three of the case studies, the top ranked segregation approach was always LandSeg (Table 7). For one of the case studies (Bay of Plenty), the top ranked segregation approach was less clear cut with the predominant approach (MillSeg) only achieving the top ranking in less than 50% of the scenarios examined.

The segregation approach that achieved the top ranking was only affected to a minor degree by stand location. In only two of 16 paired comparisons (12%) was there a change in the top ranked approach when stand locations were swapped within case study regions, from MillSeg to NoSeg for one pair and from CPYSeg to LandSeg for the other pair. Statistically significant increases in total mill door values were found with PHISeg (5.3%), with LandSeg (7.4%) and with MillSeg (0.6%) approaches (Table 8). PHISeg and LandSeg were not statistically different from each other. No significant difference was found between CPYSeg and NoSeg.

The magnitude of the improvements in mill door value resulting from the different segregation approaches was not consistent between all case studies (Table 8). The benefits of segregation were greatest in the Northland case study for all approaches and lowest in the Bay of Plenty case study for the PHISeg and LandSeg approaches. The benefits of segregation in the Nelson/Marlborough and Southland/Otago case studies tended to be similar to each other and between those of the other two case studies.

3.3 Allocation of wood to export and domestic markets

If there were no segregation based on internal wood properties (NoSeg), two thirds of the wood was allocated to the export market (Table 9). The smallest export volume occurred with CPYSeg (43%) or in the forest with the PHISeg and LandSeg (38%) approaches. The choice of segregation approach had no significant effect on the amount of wood allocated to fibre mills (9%) and a limited effect on the amount of waste generated (5%). The volume allocated to appearance (19%) and structural mills (29%) was greatest with the PHISeg or LandSeg approaches and the allocation of wood to these mill types was lowest with NoSeg.

Not unexpectedly, there were differences in the volume allocation among case study regions. These differences were for appearance, structural and fibre mills, but not for export or waste. No volume was allocated to the appearance mill in the Northland case study under any of the approaches. Significantly lower proportions of volume were allocated to the appearance mill in the Otago/Southland case study under the NoSeg and MillSeg approaches but not for the PHISeg and LandSeg approaches. Compared with the other three case studies, the structural mill in Northland was allocated significantly more volume under all approaches. The Bay of Plenty and Nelson/Marlborough case studies were allocated the least structural volume under all approaches, and there was no significant difference between these two regions. In the Northland and Nelson/Marlborough case studies, 4 to 5% more volume was allocated to fibre under all segregation approaches than in the Bay of Plenty and Otago/Southland case studies.

4 Discussion

SEGMOD has provided a framework for investigating the impacts of different segregation approaches from the perspective of two parties in the supply chain. Across the four case studies, which represent differences in forest resource and processing infrastructure, we found that no single approach for segregating stands, stems and logs was consistently better from the financial perspective of a forest grower or wood processor. This finding is consistent with a previous study showing that the best approach for segregating radiata pine logs based on internal wood properties depended on the type of stand being harvested (Wood Quality Initiative, unpublished data). For the range of forest and market conditions investigated across the four case studies, segregation based on pre-harvest inventory (PHISeg) was most often the top ranked approach (43% of cases) based on overall stumpage values. However, other approaches, including NoSeg, were found to yield higher stumpage values for 57% of the scenario sets evaluated. The segregation approaches yielding the highest stumpage values differed among case studies and, except in Northland where LandSeg was always the top ranked approach, were not consistent within a case study region. For example, in only one case study was NoSeg the best approach and this was for unpruned stands that were being evaluated with an equal focus on domestic and export markets.

Compared with NoSeg, PHISeg yielded a 10% increase in overall stumpage value. This was similar to the level of increase for LandSeg and higher than for MillSeg. The relative level of increase varied between case studies, between market horizons and market foci, but not between terrain types and pruning types. Swapping the stand location within a region only infrequently changed the top ranked segregation approach for a given stand. CPYSeg was found to result in lower overall stumpage value than NoSeg, although it must be stressed that it was only evaluated as an option for the Bay of Plenty case study. This finding is consistent with an early study by Sessions et al. (2005) which showed that, although central sort yards provide an opportunity to more closely examine log characteristics than can be undertaken at a landing in the forest, increased handling costs in the yards result in lower net returns.

A concern that is often expressed is that segregation will increase the number of log sorts, which in turn results in increased production and logistics costs (Nurminen and Heinonen 2007; Nurminen et al. 2009). In New Zealand, it has been suggested that productivity, and by implications cost, of wood harvesting, wood transport and handling and loading of logs at New Zealand’s export ports could be improved significantly by reducing the number of log sorts (Woodweek 2014). In the case studies with SEGMOD, a greater number of sorts were allowed for when segregating logs based on internal wood properties compared with sorting based only on external characteristics. Despite increased costs associated with segregation due to both the tools and methods being used and the number of sorts being handled, segregation led to higher net returns for the forest owner, in most cases. However, this result is dependent on the assumed costs of segregation which were based on information provided by case study participants. Within SEGMOD, there is the ability to examine the sensitivity of the results to different assumptions around the costs of segregation. Segregating stands, stems or logs based on internal wood properties was also shown to create higher value for mill owners for most of the scenario sets evaluated, but it should be noted that mill door values also included the value of logs exported.

In three of the four case studies, there was consistency in the top ranked segregation approach in terms of improvements in unadjusted mill door values. For these three studies, LandSeg was found to be the best approach for all forest and market conditions evaluated. There were significant differences, however, in the level of improvement in value compared with the NoSeg approach. In particular, Bay of Plenty differed greatly from the other three regions and MillSeg (47%) and CPYSeg (20%) were the most common top ranked approaches. The exact reasons why this region differs from the others are not known. NoSeg was found to lead to greater proportions of stand volume being exported, particularly if there was an equal focus on export and domestic markets. This was not unexpected as export log prices are generally higher than domestic log prices (Ministry for Primary Industries 2018) and export log grade specification are mostly based around external attributes. Export volume allocation differed between segregation approaches but not between regions.

While SEGMOD provides a framework for examining the relative performance of different segregation approaches for a given set of stand and market conditions, there are a number of important limitations related to the model itself and its application to the four case studies. Firstly, it should be noted that log volume recoveries and grade recoveries were modelled based on historic studies and are, therefore, specific to the resource and mill configurations in these studies. They do not relate specifically to the mills participating in the case studies, and individual mills may obtain volume and grade recoveries that differ from those predicted by the models. Secondly, it should also be noted that all costs (harvesting, transport, CPY, forest inventory and mill operating) and prices (lumber, fibre, export logs) used in the case studies were indicative only. For commercial sensitivity reasons, forest and mill owners were only asked to provide indicative values. The values used, therefore, may or may not relate specifically to the forest owners and mills participating in the case studies. Through the case studies, we have demonstrated that the segregation approach that provides the greatest benefit and the magnitude of this benefit is affected by forest and market conditions. Therefore, it is to be expected that an individual forest grower or wood processor would obtain different results upon entering more specific cost and price information. Thirdly, we assumed that certain types of segregation could only be done at various points in the supply chain and also made assumptions about how segregation would be carried out. For example, we assumed that in a mill, logs that did not meet a particular specification would be downgraded, re-cut to an export length and then transported to the port for subsequent export. This creates a large penalty for this type of segregation, which may explain why it rarely achieved the top ranking, except in the Bay of Plenty case study. Rather than downgrade logs, sawmillers may process these logs using a different sawing pattern so that they achieve a reduced grade recovery. This could be incorporated into SEGMOD through updating the sawing models.

Despite being developed for radiata pine, SEGMOD is not limited to being applied to this species under New Zealand conditions. Provided that the required input information can be obtained for other species and models describing the relationships between log attributes and product outturn exist, it can be applied to other species and to situations outside of New Zealand.

5 Conclusions

Through the development and application of SEGMOD, we demonstrated that segregating radiata pine logs based on internal wood properties—acoustic velocity and incidence of resin—generally led to improvements in overall stumpage value and mill door value. For a single case study region, not segregating logs based on internal wood properties (NoSeg) was the best option for a quarter and an eighth of the scenario sets evaluated, based on stumpage value and mill door value, respectively. NoSeg was most likely to be found as best in unpruned stands. Segregating stands based on PHI assessments or logs at the landing would appear to be the best approaches from the forest owner’s perspective. The size of the increase in stumpage value was found to be dependent on market horizon and focus. The best approach, in terms of total mill door value, was found to be LandSeg. It could be concluded, however, that the best segregation approach may depend on resource, market and processing infrastructure in the region of interest.

References

Amishev D, Murphy GE (2009) Estimating breakeven prices for Douglas-fir veneer quality logs from stiffness graded stands using acoustic tools. For Prod J 59(4):45–52

Bilek EM (2009) LSY: documentation for a spreadsheet tool to evaluate log-sort yard economics. General Technical Report FPL-GTR-184. USDA Forest Service, Forest Products Laboratory, Madison, WI

Briggs D (1989) Tree value system – description and assumptions. General Technical Report PNW-GTR-239. UDSA Forest Service, Pacific Northwest Research Station, Portland, OR

Cass RD, Baker SA, Greene WD (2009) Cost and productivity impacts of product sorting on conventional ground-based timber harvesting operations. For Prod J 59(11):108–114. https://doi.org/10.13073/0015-7473-59.11.108

Cown DJ (1978) Comparison of the Pilodyn and Torsiometer methods for the rapid assessment of wood density in living trees. N Z J For Sci 8:384–391

Cown DJ, Kimberley MO, Whiteside ID (1987) Conversion and grade recoveries from radiata pine logs. In: Kininmonth JA (ed) Proceedings of the conversion planning conference. FRI Bulletin, vol 128. Ministry of Forestry, Forest Research Institute, Wellington, pp 147–161

Deadman MW, Goulding CJ (1978) A method for assessment of recoverable volume by log types. N Z J For Sci 9(2):225–239

Forest Owners Association (2017) New Zealand plantation forest industry 2016/17 facts & figures. New Zealand Forest Owners Association Inc., Wellington, New Zealand

Fox TR, Jokela EJ, Allen HL (2007) The development of pine plantation silviculture in the southern United States. J For 105(7):337–347

Gardiner B, Moore J (2014) Creating the wood supply of the future. In: Fenning TM (ed) Challenges and opportunities for the world’s forests in the 21st century. Springer Science+Business Media, Dordrecht, pp 677–704. https://doi.org/10.1007/978-94-007-7076-8_30

Kimberley MO, Cown DJ, McKinley RB, Moore JR, Dowling LJ (2015) Modelling variation in wood density within and among trees in stands of New Zealand-grown radiata pine. N Z J For Sci 45(1). https://doi.org/10.1186/s40490-015-0053-8

Manley B (2002) Fitness for purpose, wood quality and the value chain. N Z J For 47(3):2

McConchie DL (2003) Field guide to assist recognition and classification of resinous defects on the bark of radiata pine. WQI Report No APP 12. Wood Quality Initiative Ltd, Rotorua, New Zealand

Ministry for Primary Industries (2018) Historic indicative New Zealand radiata pine log prices. http://www.mpi.govt.nz/news-and-resources/open-data-and-forecasting/forestry/wood-product-markets/historic-indicative-new-zealand-radiata-pine-log-prices/. Accessed 08/03/2018

Moore JR, Cown DJ (2015) Processing of wood for wood composites. In: Ansell MP (ed) Wood composites. Woodhead Publishing, Cambridge, pp 27–45. https://doi.org/10.1016/b978-1-78242-454-3.00002-0

Moore JR, Cown DJ (2017) Corewood (juvenile wood) and its impact on wood utilisation. Current Forestry Reports 3(2):107–118. https://doi.org/10.1007/s40725-017-0055-2

Murphy G, Cown D (2015) Stand, stem and log segregation based on wood properties: a review. Scand J For Res 30:1–47. https://doi.org/10.1080/02827581.2015.1055791

Murphy G, Lyons J, O’Shea M, Mullooly G, Keane E, Devlin G (2010) Management tools for optimal allocation of wood fibre to conventional log and bio-energy markets in Ireland: a case study. Eur J For Res 129(6):1057–1067. https://doi.org/10.1007/s10342-010-0390-3

Nurminen T, Heinonen J (2007) Characteristics and time consumption of timber trucking in Finland. Silva Fennica 41(3):471–487

Nurminen T, Korpunen H, Uusitalo J (2009) Applying the activity-based costing to cut-to-length timber harvesting and trucking. Silva Fennica 43(5):847–870

Palmer DJ, Kimberley MO, Cown DJ, McKinley RB (2013) Assessing prediction accuracy in a regression kriging surface of Pinus radiata outerwood density across New Zealand. For Ecol Manag 308:9–16. https://doi.org/10.1016/j.foreco.2013.07.024

Park J (1989) Pruned log index. N Z J For Sci 19(1):44–53

Perstorper M, Pellicane PJ, Kliger IR, Johansson G (1995) Quality of timber products from Norway spruce. Part 1. Optimization, key variables, and experimental study. Wood Sci Technol 29(3):157–170. https://doi.org/10.1007/BF00204581

Pnevmaticos SM, Mann SH (1972) Dynamic programming in tree bucking. For Prod J 22(2):26–30

Sessions J, Boston K, Hill R, Stewart R (2005) Log sorting location decisions under uncertainty. For Prod J 55(12):53–57

Standards New Zealand (1993) Timber Structures Amendment 4 NZS3603:1993. Standards New Zealand, Wellington, New Zealand

Tolan A, Visser R (2015) The effect of the number of log sorts on mechanized log processing productivity and value recovery. Int J For Eng 26(1):36–47. https://doi.org/10.1080/14942119.2015.1011404

Wang X, Carter P, Ross RJ, Brashaw BK (2007) Acoustic assessment of wood quality of raw forest materials—a path to increased profitability. For Prod J 57(5):6–14

Woodweek (2014) Call for less log sorts. http://www.woodweek.com/index.cfm?id=290#4. Accessed 07/03/2018

Zobel BJ, Sprague JR (1998) Juvenile wood in forest trees. Springer, Berlin

Acknowledgements

We would like to thank those New Zealand forestry companies and wood processors who gave permission for their data to be used in the four case studies reported here. Mark Kimberley and Joel Gordon (Scion) helped to recreate SAWMOD, and Solid Wood Innovation Ltd. gave permission for their sawing study data to be used.

Funding

This work was supported by the New Zealand Ministry for Business, Innovation and Employment (C04X1306) and the Forest Growers’ Levy Trust as part of the Growing Confidence in Forestry’s Future research programme.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Jean-Michel Leban

Contribution of the co-authors GEM developed the SEGMOD model, analysed the data from the case studies and wrote the paper. JRM assisted with facilitation of the case studies, providing data on wood quality and helped write the manuscript.

Rights and permissions

About this article

Cite this article

Murphy, G.E., Moore, J.R. SEGMOD—a techno-economic model for evaluating the impact of segregation based on internal wood properties. Annals of Forest Science 75, 73 (2018). https://doi.org/10.1007/s13595-018-0755-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13595-018-0755-1