Abstract

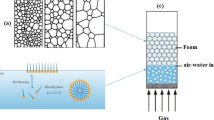

A desorption method based on a thermodynamic approach has recently been developed to evaluate the behaviour of dairy concentrates during drying. Involving overall heat and mass balance throughout the dryer, this approach can determine several key gas-feed parameters for industrial spray-drying processes. Spray-drying software (SD2P®) was then designed following this approach to predict the optimal inlet drying air temperatures with acceptable accuracy (95–99% accuracy) for spray-drying of dairy products. However, the mass change of the sample was indirectly determined from the change in the relative humidity of the air during desorption, which could be a source of error below the detection threshold of the thermo-hygrometric sensor. In order to measure directly the mass change during drying by desorption, a modified drying-by-desorption method was investigated in this study. The novel method used a precise microbalance and a modified desorption cell which permitted measurement of the mass change of the sample and the relative humidity of the air at the same time. Different materials (water, skim milk, infant formulae, etc.) were tested using this new method. The results obtained with direct (microbalance) and indirect (thermo-hygrometer) measurements were found to be highly consistent (coefficient of determination 1). This confirmed that the mass change estimation by the original desorption method was correct overall under current conditions. Moreover, the proposed new desorption method makes it possible to monitor water transfer with constant accuracy over the entire desorption process, thus permitting reliable study of the mass transfer phenomena throughout experiments.

Similar content being viewed by others

References

Fu N, Woo MW, Lin XQ, Zhou Z, Chen XD (2011) Reaction engineering approach (REA) to model the drying kinetics of droplets with different initial sizes—experiments and analyses. Chem Eng Sci 66:1738–1747

Lin XQ, Chen XD (2006) A model for drying of an aqueous lactose droplet using the reaction engineering approach. Dry Technol 24:1329–1334

Patel K, Chen XD, Jeantet R, Schuck P (2010) One-dimensional simulation of co-current, dairy spray drying systems—pros and cons. Dairy Sci Technol 90:181–210

Schuck P, Roignant M, Brulé G, Davenel A, Famelart MH, Maubois JL (1998) Simulation of water transfer in spray drying. Dry Technol 16(7):1371–1393

Schuck P, Dolivet A, Méjean S, Zhu P, Blanchard E, Jeantet R (2009) Drying by desorption: a tool to determine spray drying parameters. J Food Eng 94:199–204

Zhu P, Méjean S, Blanchard E, Jeantet R, Schuck P (2011a) Prediction of dry mass glass transition temperature and the spray drying behaviour of a concentrate using a desorption method. J Food Eng 105:460–467

Zhu P, Patel K, Lin S, Méjean S, Blanchard E, Chen XD, Schuck P, Jeantet R (2011b) Simulating industrial spray drying operations using a reaction engineering approach and a modified desorption method. Dry Technol 29(04):419–428

Acknowledgements

The authors thank the Laiterie de Montaigu (France) for their scientific and financial support for this study.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Zhu, P., Méjean, S., Blanchard, E. et al. Prediction of drying of dairy products using a modified balance-based desorption method. Dairy Sci. & Technol. 93, 347–355 (2013). https://doi.org/10.1007/s13594-012-0099-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13594-012-0099-9