Abstract

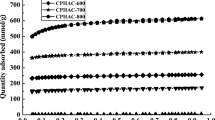

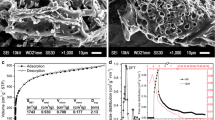

Activated carbon with high specific surface area has been produced from green alga Ulva lactuca by using zinc chloride (ZnCl2) solution as an activating agent under carbonization temperature ranged from 500 to 900 °C. The effects of carbonization temperatures, holding time, and amount of ZnCl2 followed by soaking in hydrochloric acid on the specific surface area, pore morphology, and mass yield of the prepared activated carbon were investigated. In this work, the activated carbon with high specific surface area was achieved using 1:2 (ZiCl2: Ulva lactuca) impregnation agent, 700 °C as activation temperature, 30 min as holding time, and soaking with 3.0 M hydrochloric acid as the optimum conditions. This condition produced an activated carbon with specific surface area (SBET) and micropore surface area (Smi) of 1486.3 and 1582.04 m2/g, respectively, with mean pore diameter (DP) of 2.39 nm. The results showed that the chemical activation by ZnCl2 is a useful technique for obtaining activated carbon from Ulva lactuca with desired pore size distributions and morphology at moderate activation temperatures.

Similar content being viewed by others

References

Alhamed YA (2006) Activated carbon from dates’ stone by ZnCl2 activation. JKAU: Eng Sci 17(2):75–100

Alslaibi TM, Abustan I, Ahmad MA, Abu Foul A (2013) A review: production of activated carbon from agricultural byproducts via conventional and microwave heating. J Chem Technol Biotechnol 88(7):1183–1190

Wang D, Wang Z, Zheng X, Tian M (2020a) Activated carbon fiber derived from the seed hair fibers of Metaplexis japonica: novel efficient adsorbent for methylene blue. Ind Crop Prod 148(2020):112319. https://doi.org/10.1016/j.indcrop.2020.112319

Guedesa RE, Lunaa AS, Torres AR (2018) Operating parameters for bio-oil production in biomass pyrolysis: a review. J ANAL APPL PYROL 129:134–149

Wang Z, Yang H, Li Y, Zheng X (2020b) A robust silk fibroin/graphene oxide aerogel fiber for the radiative heating textiles. ACS Appl Mater Interfaces 12(13):15726–15736. https://doi.org/10.1021/acsami.0c01330

Amuda OS, Olayiwola AO, Alade AO, Farombi AG, Adebisi SA (2014) Adsorption of methylene blue from aqueous solution using steam-activated carbon produced from Lantana camara stem. J Environ Prot 5:1352–1363

Gerçel Ö, Özcan A, Özcan AS, Gerçel HF (2007) Preparation of activated carbon from a renewable bio-plant of Euphorbia rigida by H2SO4 activation and its adsorption behavior in aqueous solutions. Appl Surf Sci 253:4843–4852

El-Sikaily A, El Nemr A, Khaled A (2011) Copper sorption onto dried red alga Pterocladia capillacea and its activated carbon. Chem Eng J 168(2):707–714

Han Q, Wang J, Goodman BA, Xie J, Liu Z (2020) High adsorption of methylene blue by activated carbon prepared from phosphoric acid treated eucalyptus residue. Powder Technol 366(2020):239–248. https://doi.org/10.1016/j.powtec.2020.02.013

Aravind Kumar J, Joshua Amarnath D, Sathish S, Anuradha Jabasingh S, Saravanan A, Hemavathy RV, Vijai Anand K, Yaashikaa PR (2019) Enhanced PAHs removal using pyrolysis-assisted potassium hydroxide induced palm shell activated carbon: batch and column investigation. J Mol Liq 279:77–87. https://doi.org/10.1016/j.molliq.2019.01.121

Marrakchi F, Ahmed MJ, Khanday WA, Asifc M, Hameed BH (2017) Mesoporous-activated carbon prepared from chitosan flakes viasingle-step sodium hydroxide activation for the adsorption of methylene. Int J Biol Macromol 98:233–239. https://doi.org/10.1016/j.ijbiomac.2017.01.119

Ajmani A, Patra C, Subbiah S, Narayanasamy S (2020) Packed bed column studies of hexavalent chromium adsorption by zinc chloride activated carbon synthesized from Phanera vahlii fruit biomass. J Environ Chem Eng 8:103825. https://doi.org/10.1016/j.jece.2020.103825

Duan X-L, Yuan C-G, Jing T-T, Yuan X-D (2019) Removal of elemental mercury using large surface area micro-porous corn cob activated carbon by zinc chloride activation. Fuel 239:830–840. https://doi.org/10.1016/j.fuel.2018.11.017

You Y, Zhang X, Li P, Lei F, Jiang J (2020) Co-production of xylooligosaccharides and activated carbons from Camellia oleifera shell treated by the catalysis and activation of zinc chloride. Bioresour Technol 306:123131. https://doi.org/10.1016/j.biortech.2020.123131

El Nemr A, Abdelwahab O, Khaled A, El Sikaily A (2006) Biosorption of direct yellow 12 from aqueous solution using green alga Ulva lactuca. Chem Ecol 22(4):253–266

Abdul Khalil HPS, Tye YY, Saurabh CK, Leh CP, Lai TK, Chong EWN, Nurul Fazita MR, Mohd Hafiidz J, Banerjee A, Syakir MI (2017) Biodegradable polymer films from seaweed polysaccharides: a review on cellulose as a reinforcement material. Express Polym Lett 11(4):244–265

Ho YB (1990) Ulva lactuca as bioindicator of metal contamination in intertidal waters in Hong Kong. Hydrobiologia 203(1–2):73–81

El-Sikaily A, El Nemr A, Khaled A, Abdelwehab O (2007) Removal of toxic chromium from wastewater using green alga Ulva lactuca and its activated carbon. J Hazard Mater 148:216–228

Salima A, Benaouda B, Noureddine B (2013) Application of Ulva lactuca and Systoceira stricta algae-based activated carbons to hazardous cationic dyes removal from industrial effluents. Water Res 47:3375–3388

Altenor S, Ncibia MC, Emmanuel E, Gaspard S (2012) Textural characteristics, physiochemical properties and adsorption efficiencies of Caribbean alga Turbinaria turbinata and its derived carbonaceous materials for water treatment application. Biochem Eng J 67:35–44

Wang M, Hao F, Li G, Huang J, Bao N, Huang L (2014) Preparation of Enteromorpha prolifera-based cetyl trimethyl ammonium bromide-doped activated carbon and its application for nickel (II) removal. Ecotoxicol Environ Saf 104:254–262

El Nemr A, El-Sikaily A, Khaled A, Abdelwahab O (2015) Removal of toxic chromium from aqueous solution, wastewater and saline water by marine red alga Pterocladia capillacea and its activated carbon. Arab J Chem 8(1):105–117

Kılıç M, Apaydın-Varol E, Pütün AE (2012) Preparation and surface characterization of activated carbons from Euphorbia rigida by chemical activation with ZnCl2, K2CO3, NaOH and H3PO4. Appl Surf Sci 261:247–254

Rouquerol, F.; Rouquerol, J.; Sing, K. S. W. (1999), Adsorption by powders and porous solids Academic Press INC. 2nd Edition, London

Rostamian R, Heidarpour M, Mousavi SF, Afyuni M (2015) Characterization and soduim sorption capacity of biochars and activated carbon prepared from rice husk. J Agric Sci Technol 17:1057–1069

Sugumaran P, Priya Susan V, Ravichandran P, Seshadri S (2012) Production and characterization of activated carbon from Banana empty fruit bunch and Delonix regia fruit pod. J Renew Sustain Ener 3:125–132

Caballero JA, Marcilla A, Conesa JA (1997) Thermogravimetric analysis of olive stones with sulphuric acid treatment. J Anal Appl Pyrolysis 4:75–88

Köseoğlu E, Akmil-Başar C (2015) Preparation, structural evaluation and adsorptive properties of activated carbon from agricultural waste biomass. AdvPowder Technol 26(3):811–818

Raveebdran K, Gauesh A, Kartic CK (1996) Pyrolysis characteristics of biomass and biomass component. Fuel 75(8):987–998

Caturla F, Molina-Sabio M, Rodriguez-Reinoso F (1991) Preparation of activated carbon by chemical activation with ZnCl2. Carbon 29(7):999–1007

Uçar S, Erdem M, Tay T, Karagöz S (2009) Preparation and characterization of activated carbon produced from pomegranate seeds by ZnCl2 activation. Appl Surf Sci 255:8890–8896

Yang H, Yan R, Chen H, Lee DH, Zheng C, Zheng C (2007) Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86:1781–1788

Qian Q, Machida M, Tatsumato H (2007) Preparation of activated carbons from cattle-manure compost by zinc chloride activation. BioresourTechnol. 98(2):353–360

Yorgun S, Vural N, Demiral H (2009) Preparation of high-surface area activated carbons from Paulownia wood by ZnCl2 activation. Microporous Mesoporous Mater 122:189–194

Encinar JM, Beltran FJ, Ramiro A, Gonzalez JF (1998) Pyrolysis/gasification of agricultural residues by carbon dioxide in the presence of different additives: influence of variables, fuel process. Technol 55:219–233

Ahmadpour A, Do DD (1997) The preparation of activated carbon from macadamianutshell by chemical activation. Carbon 35:1723–1732

Di Blasi C, Branca C, Galgano A (2008) Products and global weight loss rates of wood decomposition catalyzed by zinc chloride. Energy Fuel 22(1):663–670

Hayashi J, Kazehaya A, Muroyama K, Watkinson AP (2000) Preparation of activated carbon from lignin by chemical activation. Carbon 38:1873–1878

Li Y, Li Y, Li L, Shi X, Wang Z (2016) Preparation and analysis of activated carbon from sewage sludge and corn stalk, Adv. Powder Technol 27(2):684–691

Ozdemir I, Şahin M, Orhan R, Erdem M (2014) Preparation and characterization of activated carbon from grape stalk by zinc chloride activation. Fuel Process Technol 125:200–206

Spahis N, Addoun A, Mahmoudi H, Ghaffour N (2008) Purification of water by activated carbon prepared from olive stones. Desalination 222:519–527

De Bore JH (1958) The shape of capillaries in the structure and properties of porous materials, in: D.H. Everett, F.S. Stone (Eds.). Butterworth, London, p 68

Guo J, Lua AC (2000) Textural characterization of activated carbon prepared from oil-palm with various impregnating agents. J Porous Mater 7(4):491–497

Balbuenat PB, Gubbins KE (1993) Theoretical interpretation of adsorption behavior of simple fluids in slit pores. Langmuir 9:1801–1814

Dos Reis GS, Wilhelmb M, De Almeida Silva TC, Rezwan K, Sampaio CH, Lima EC, De Souza SMAGU (2016) The use of design of experiments for the evaluation of the productionof surface rich activated carbon from sewage sludge via microwave and conventional pyrolysis. Appl Therm Eng 93:590–597

Prenzel T, Guedes TLM, Schluter F, Wilhelm M, Rezwan K (2014) Tailoring surfaces of hybrid ceramics for gas adsorption – from alkanes to CO2. Sep Purif Technol 129:80–89

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Reporting physisorption data for gas/solid interface with special reference to the determination of surface area and porosity. Pure Appl Chem 57:603–619

Oliveira LCA, Pereira E, Guimaraes IR, Vallone A, Pereirac M, Mesquita JP, Sapag K (2009) Preparation of activated carbons from coffee husks utilizing FeCl3 and ZnCl2 as activating agents. J Hazard Mater 165:87–94

Kragović M, Stojmenović M, Petrović J, Loredo J, Pašalić S, Nedeljković A, Ristović I (2019) Influence of alginate encapsulation on point of zero charge (pHpzc) and thermodynamic properties of the natural and Fe(III) - modified zeolite. Proc Manuf 32:286–293. https://doi.org/10.1016/j.promfg.2019.02.216

Gergova K, Petrov N, Minkova V (1993) Comparison of adsorption characteristics of various activated carbons. J Chem Technol Biotechnol 56:77–82

Akl MA, Youssef AFM, Hassan AH, Maher H (2016) Synthesis, characterization and evaluation of peanut shells-derived activated carbons for removal of methomyl from aqueous solutions. J Environ Anal Toxicol 6:352. https://doi.org/10.4172/2161-0525.1000352

Hassan AF, Youssef AM (2014) Preparation and characterization of microporous NaOH activated carbons from hydrofluoric acid leached rice husk and its application for lead (II) adsorption. Carbon Lett 15(1):57–66

Youssef AM, Hassan AF, Safan M (2013) Modeling and characterization of steam-activated carbons developed from cotton stalks. Carbon Lett 14(1):14–21

Liu S, Pan M, Feng Z, Qin Y, Wang Y, Tan L, Sun T (2020) Ultra-high adsorption of tetracycline antibiotics on garlic skin-derived porous biomass carbon with high surface area. New J Chem 44:1097–1106. https://doi.org/10.1039/c9nj05396d

Li H, Li Y, Chen Y, Yin M, Jia T, He S, Deng Q, Wang S (2019) Carbon tube clusters with nanometer walls thickness, micrometer diameter from biomass, and its adsorption property as bioadsorbent. ACS Sustain Chem Eng 7:858–866. https://doi.org/10.1021/acssuschemeng.8b04486

Xie J, Wu C, Fan F, Li X, Guo A, Zhang X, Gu J, Deng Q (2019) Adsorption properties of natural biomass tube clusters for dyes. Funct Mater Lett 12(6):1941001. https://doi.org/10.1142/S1793604719410017

Li Y, Li Y, Zang H, Chen L, Meng Z, Li H, Ci L, Du Q, Wang D, Wang C, Li H, Xia Y (2018) ZnCl2-activated carbon from soybean dregs as a high efficiency adsorbent for cationic dye removal: isotherm, kinetic, and thermodynamic studies. Environ Technol 30:1–24. https://doi.org/10.1080/09593330.2018.1554006

Kırbıyık Ç, Pütün AE, Pütün E (2017) Equilibrium, kinetic, and thermodynamic studies of the adsorption of Fe(III) metal ions and 2,4-Dichlorophenoxyacetic acid onto biomass-based activated carbon by ZnCl2 activation. Surf Interfaces 8:182–192

Liu Y, Wang Y, Zhang G, Liu W, Wang D, Dong Y (2016) Preparation of activated carbon from willow leaves and evaluation in electric double-layer capacitors. Mater Lett 176:60–63

Sayğılı H, Güzel F (2016) High surface area mesoporous activated carbon from tomato processing solid waste by zinc chloride activation: process optimization, characterization and dyes adsorption. J Clean Prod 113:995–1004

Kumar A, Jena HM (2015) High surface area microporous activated carbons prepared from fox nut (Euryale ferox) shell by zinc chloride activation. Appl Surf Sci 356:753–761

Mahamad MN, Zaini MAA, Zakaria ZA (2015) Preparation and characterization of activated carbon from pineapple waste biomass for dye removal. Int Biodeterior Biodegrad 102:274–280

Angin D (2014) Production and characterization of activated carbon from sour cherry stones by zinc chloride. Fuel 115:804–811

Zhang Z, Luo X, Liu Y, Zhou P, Ma G, Lei Z, Lei L (2014) A low cost and highly efficient adsorbent (activated carbon) prepared from waste potato residue. J Taiwan Inst Chem Eng 49:206–211

Angın D, Altintig E, Köse TE (2013) Influence of process parameters on the surface and chemical properties of activated carbon obtained from biochar by chemical activation. Bioresour Technol 148:542–549

Gao JJ, Qin YB, Zhou T, Cao DD, Xu P, Hochstetter D, Wang YF (2013) Adsorption of methylene blue onto activated carbon produced from tea (Camellia sinensisL.) seed shells: kinetics, equilibrium, and thermodynamics studies. J Zhejiang Univ Sci B 14:650–658

Durala MU, Cavas L, Papageorgiou SK, Katsaros FK (2011) Methylene blue adsorption on activated carbon prepared from Posidonia oceanica (L.) dead leaves: kinetics and equilibrium studies. Chem Eng J 168:77–85

Li Y, Dua Q, Liu T, Qib Y, Zhang P, Wanga Z, Xia Y (2011) Preparation of activated carbon from Enteromorpha prolifera and its use on cationic red X-GRL removal. Appl Surf Sci 257:10621–10627

Sahu JN, Acharya J, Meikap BC (2010) Optimization of production conditions for activated carbons fromTamarind wood by zinc chloride using response surface methodology. Bioresour Technol 101:1974–1982

Sathishkumara M, Vijayaraghavan K, Binupriya AR, Stephan AM, Choi JG, Yun SE (2008) Porogen effect on characteristics of banana pith carbon and the sorption of dichlorophenols. J Colloid Interface Sci 320:22–29

Önal Y, Akmil-Başar C, Sarıcı-Özdemir Ç (2007a) Elucidation of the naproxen sodium adsorption onto activated carbon prepared from waste apricot: kinetic, equilibrium and thermodynamic characterization. J Hazard Mater 148:727–734

Önal Y, Akmil-Başara C, Sarıcı-Özdemira Ç, Erdoğanb S (2007b) Textural development of sugar beet bagasse activated with ZnCl2. J Hazard Mater 142:138–143

Namasivayam C, Sangeetha D (2006) Recycling of agricultural solid waste, coir pith: removal of anions, heavy metals, organics and dyes from water by adsorption onto ZnCl2activated coir pith carbon. J Hazard Mater 135:449–452

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shoaib, A.G.M., El-Sikaily, A., El Nemr, A. et al. Testing the carbonization condition for high surface area preparation of activated carbon following type IV green alga Ulva lactuca. Biomass Conv. Bioref. 12, 3303–3318 (2022). https://doi.org/10.1007/s13399-020-00823-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00823-w