Abstract

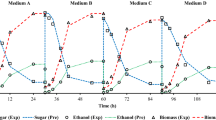

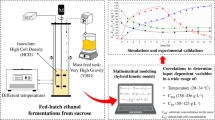

Mathematical models not only ensure information about kinetic-metabolic nature of fermentations, but also facilitate their control and optimization. In the study, flexible ten models were evaluated and employed to describe the ethanol fermentation in a biofilm reactor with a carob extract medium (CEM). Findings indicated that W model well fitted the experimental data of cell growth (root mean square error (RMSE) = 0.289 g/L, mean absolute error (MAE) = 0.237 g/L, regression coefficient (R2) = 0.9944, bias factor (BF) = 1.021, and accuracy factor (AF) = 1.047), ethanol production (RMSE = 1.609 g/L, MAE = 1.277 g/L, R2 = 0.9774, BF = 1.178, and AF = 1.283), and substrate consumption (RMSE = 2.493 g/L, MAE = 1.546 g/L, R2 = 0.9931, BF = 1.001 and AF = 1.053). In the prediction of kinetic parameters, W model also gave better and well-directed results compared with the other mathematical models used in the study. When an independent set of experimental data was used in the validation of mathematical models, similar validation results were obtained and W model was also successful. Consequently, W model could be used for more progress of fermentation process in biofilm reactor with CEM, which can serve as a universal equation.

Similar content being viewed by others

Abbreviations

- μ max :

-

Maximum specific growth rate (1/h)

- AF :

-

Accuracy factor (−)

- A m :

-

Upper asymptote (g/L)

- A o :

-

Lower asymptote (g/L)

- A t :

-

The predicted biomass, ethanol, and sugar concentration at time “t” (g/L)

- BF :

-

Bias factor (−)

- DF :

-

Degree of freedom (−)

- e :

-

Euler number, 2.718 (−)

- h o :

-

A parameter calculating the initial physiology state of the cells (g/L)

- k :

-

A parameter governing the rate at which the response variable approaches its potential maximum (−)

- m :

-

Slope (−)

- MAE:

-

Mean absolute error (g/L)

- MGM:

-

Modified Gompertz model (−)

- MLM:

-

Modified logistic model (−)

- MMF:

-

Morgan-Mercer-Flodin model (−)

- MRM:

-

Modified Richards model (−)

- n :

-

Number of observations (−)

- P :

-

Ethanol concentration (g/L)

- P max :

-

Maximum ethanol production (g/L)

- P min :

-

Minimum ethanol production (g/L)

- Q :

-

Maximum production, consumption, and growth rate (g/L)

- Q P :

-

Maximum ethanol production rate (g/L)

- Q S :

-

Maximum sugar consumption rate (g/L)

- Q X :

-

Maximum cell growth rate (g/L)

- R 2 :

-

Regression coefficient (−)

- R-MGM:

-

Re-modified Gompertz model (−)

- R-MLM:

-

Re-modified logistic model (−)

- R-MRM:

-

Re-modified Richards model (−)

- RMSE:

-

Root mean square error (g/L)

- RSC:

-

Residual sugar concentration (g/L)

- RSS:

-

Residual sum of squares (g/L)

- S max :

-

Maximum sugar concentration (g/L)

- S min :

-

Minimum sugar concentration (g/L)

- SUY:

-

Sugar utilization yield (%)

- t :

-

Sampling time (h)

- TY:

-

Theoretical ethanol yield (%)

- v :

-

Dimensionless shape parameter (−)

- X :

-

Biomass concentration (g/L)

- X max :

-

Maximum biomass production (g/L)

- X min :

-

Minimum biomass production (g/L)

- x t :

-

Experimental value at time “t” (g/L)

- Y P/S :

-

Ethanol yield (%)

- Y P/X :

-

Product yield per biomass (g ethanol/g cell)

- y t :

-

Predicted value at time “t” (g/L)

- Y X/S :

-

Biomass yield (%)

- β :

-

Growth displacement (−)

- δ :

-

Allometric constant (−)

- λ :

-

Lag time (h)

- Φ-value:

-

The relative error sum of squares (−)

References

Fatehi P (2013) Recent advancements in various steps of ethanol, butanol, and isobutanol productions from woody materials. Biotechnol Prog 29(2):297–310

FAOSTAT (2018) Food and agriculture Organization of the United Nations. http://www.fao.org/faostat/en/#compare. Accessed 01 Sept 2018

Prasad S, Singh A, Joshi H (2007) Ethanol as an alternative fuel from agricultural, industrial and urban residues. Resour Conserv Recycl 50(1):1–39

Menon V, Rao M (2012) Trends in bioconversion of lignocellulose: biofuels, platform chemicals & biorefinery concept. Prog Energy Combust Sci 38(4):522–550

Battle I, Tous J (1997) Carob tree: Ceratonia siliqua L.-promoting the conservation and use of underutilized and neglected crops. 17. Institute of Plant Genetics and Crop Plant Research, Gatersleben/International Plant Genetic Resources Institute, Rome

Oziyci HR, Tetik N, Turhan I, Yatmaz E, Ucgun K, Akgul H, Gubbuk H, Karhan M (2014) Mineral composition of pods and seeds of wild and grafted carob (Ceratonia siliqua L.) fruits. Sci Hortic 167:149–152

Germec M, Turhan I, Demirci A, Karhan M (2016) Effect of media sterilization and enrichment on ethanol production from carob extract in a biofilm reactor. Energy Sources, Part A: Recover Util Environ Eff 38(21):3268–3272

Germec M, Turhan I, Karhan M, Demirci A (2015) Ethanol production via repeated-batch fermentation from carob pod extract by using Saccharomyces cerevisiae in biofilm reactor. Fuel 161:304–311

Turhan I, Bialka KL, Demirci A, Karhan M (2010) Ethanol production from carob extract by using Saccharomyces cerevisiae. Bioresour Technol 101(14):5290–5296

Yatmaz E, Turhan I, Karhan M (2013) Optimization of ethanol production from carob pod extract using immobilized Saccharomyces cerevisiae cells in a stirred tank bioreactor. Bioresour Technol 135:365–371

Sarris D, Papanikolaou S (2016) Biotechnological production of ethanol: biochemistry, processes and technologies. Eng Life Sci 16(4):307–329

RFA (2016) Renewable Fuel Association of the United Nations. http://www.ethanolrfa.org/resources/industry/statistics/#1456770302650-ba1c280f-bad8;. Accessed 08 March 2016

Esfahanian M, Rad AS, Khoshhal S, Najafpour G, Asghari B (2016) Mathematical modeling of continuous ethanol fermentation in a membrane bioreactor by pervaporation compared to conventional system: genetic algorithm. Bioresour Technol 212:62–71

Mishra A, Sharma AK, Sharma S, Bagai R, Mathur AS, Gupta RP, Tuli DK (2016) Lignocellulosic ethanol production employing immobilized Saccharomyces cerevisiae in packed bed reactor. Renew Energy 98:57–63

Ercan D, Demirci A (2015) Current and future trends for biofilm reactors for fermentation processes. Crit Rev Biotechnol 35(1):1–14

Cheng K-C, Demirci A, Catchmark JM, Puri VM (2011) Effects of initial ammonium ion concentration on pullulan production by Aureobasidium pullulans and its modeling. J Food Eng 103(2):115–122

da Silva NB, Longhi DA, Martins WF, Laurindo JB, de Aragão GMF, Carciofi BAM (2017) Modeling the growth of Lactobacillus viridescens under non-isothermal conditions in vacuum-packed sliced ham. Int J Food Microbiol 240:97–101

Dammak M, Hadrich B, Barkallah M, Hentati F, Hlima HB, Pichon C, Denis M, Fendri I, Michaud P, Abdelkafi S (2018) Modelling Tetraselmis sp. growth-kinetics and optimizing bioactive-compound production through environmental conditions. Bioresour Technol 249:510–518

de Jesus S, Maciel Filho R (2010) Modeling growth of microalgae Dunaliella salina under different nutritional conditions. Am J Biochem Biotechnol 6(4):279–283

Farliahati M, Mohamed M, Rosfarizan M, Tri Puspaningsih N, Ariff A (2009) Kinetics of xylanase fermentation by recombinant Escherichia coli DH5α in shake flask culture. Am J Biochem Biotechnol 5(3):110–118

Germec M, Karhan M, Bialka KL, Demirci A, Turhan I (2018) Mathematical modeling of lactic acid fermentation in bioreactor with carob extract. Biocatal Agric Biotechnol 14:254–263

Germec M, Kartal FK, Guldali H, Bilgic M, Isci A, Turhan I (2016) Obtaining growth curves for Scheffersomyces stipitis strains and their modeling. Sci Bull Ser F Biotechnol 20:263–268

Germec M, Turhan I (2018) Ethanol production from acid-pretreated and detoxified tea processing waste and its modeling. Fuel 231:101–109

Gonçalves LDA, Piccoli RH, Peres AP (2017) Predictive modeling of Pseudomonas fluorescens growth under different temperature and pH values. Braz J Microbiol 48(2):352–358

Dodić JM, Vučurović DG, Dodić SN, Grahovac JA, Popov SD, Nedeljković NM (2012) Kinetic modelling of batch ethanol production from sugar beet raw juice. Appl Energy 99:192–197

Sablani SS, Datta AK, Rahman MS, Mujumdar AS (2006) Handbook of food and bioprocess modeling techniques. CRC Press, Boca Raton

Baranyi J, Roberts TA (1994) A dynamic approach to predicting bacterial growth in food. Int J Food Microbiol 23(3–4):277–294

Gompertz B (1825) On the nature of the function expressive of the law of human mortality, and on a new mode of determining the value of life contingencies. Philos Trans R Soc Lond 115:513–583

Morgan PH, Mercer LP, Flodin NW (1975) General model for nutritional responses of higher organisms. Proc Natl Acad Sci 72(11):4327–4331

Pearl R, Reed LJ (1920) On the rate of growth of the population of the United States since 1790 and its mathematical representation. Proc Natl Acad Sci 6(6):275–288

Richards F (1959) A flexible growth function for empirical use. J Exp Bot 10(2):290–301

Stannard C, Williams A, Gibbs P (1985) Temperature/growth relationships for psychrotrophic food-spoilage bacteria. Food Microbiol 2(2):115–122

Weibull W (1951) A statistical distributipon function of wide applicability. J Appl Mech 9:293–297

Zwietering M, Jongenburger I, Rombouts F, Van't Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56(6):1875–1881

Ho K, Pometto A, Hinz PN, Dickson JS, Demirci A (1997) Ingredient selection for plastic composite supports for L-(+)-lactic acid biofilm fermentation by Lactobacillus casei subsp. rhamnosus. Appl Environ Microbiol 63(7):2516–2523

Germec M (2014) Ethanol production in biofilm reactor via repeated-batch fermentation using carob pod extract. Master, Akdeniz University, Antalya, Turkey

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31(3):426–428

Henderson P, Seaby R, Somes R (2006) Growth II. Pisces Conservation Ltd, Lymington, England

Germec M, Ozcan A, Yilmazer C, Tas N, Onuk Z, Demirel F, Turhan I (2017) Ethanol fermentation from microwave-assisted acid pretreated raw materials by Scheffersomyces stipitis. AgroLife Sci J 6(1):112–118

Germec M, Turhan I (2018) Ethanol production from acid-pretreated and detoxified rice straw as sole renewable resource. Biomass Convers Biorefin 8(3):607–619

Chai T, Draxler RR (2014) Root mean square error (RMSE) or mean absolute error (MAE)?–arguments against avoiding RMSE in the literature. Geosci Model Dev 7(3):1247–1250

Ross T (1996) Indices for performance evaluation of predictive models in food microbiology. J Appl Microbiol 81(5):501–508

Skandamis PN, Nychas G-JE (2000) Development and evaluation of a model predicting the survival of Escherichia coli O157: H7 NCTC 12900 in homemade eggplant salad at various temperatures, pHs, and oregano essential oil concentrations. Appl Environ Microbiol 66(4):1646–1653

Ross T (1999) Predictive food microbiology models in the meat industry. Meat and Livestock Australia

Feng J, Zhang J-S, Jia W, Yang Y, Liu F, Lin C-C (2014) An unstructured kinetic model for the improvement of triterpenes production by Ganoderma lucidum G0119 based on nitrogen source effect. Biotechnol Bioprocess Eng 19(4):727–732

Cheng K-C, Demirci A, Catchmark JM, Puri VM (2010) Modeling of pullulan fermentation by using a color variant strain of Aureobasidium pullulans. J Food Eng 98(3):353–359

Cayré ME, Vignolo G, Garro O (2003) Modeling lactic acid bacteria growth in vacuum-packaged cooked meat emulsions stored at three temperatures. Food Microbiol 20(5):561–566

Fan Y, Wang Y, Qian P-Y, Gu J-D (2004) Optimization of phthalic acid batch biodegradation and the use of modified Richards model for modelling degradation. Int Biodeterior Biodegrad 53(1):57–63

van Boekel MAJS (2002) On the use of the Weibull model to describe thermal inactivation of microbial vegetative cells. Int J Food Microbiol 74:139–159

Piegorsch WW, Bailer AJ (2005) Analyzing environmental data. John Wiley & Sons, Hoboken

Suresh S, Srivastava V, Sakthivel S, Arisutha S (2018) Kinetic modeling of ethanol production for substrate–microbe system. In: Biorefining of Biomass to Biofuels. Springer, Berlin, pp 361–372

Marquardt DW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11(2):431–441

Çelekli A, Yavuzatmaca M (2009) Predictive modeling of biomass production by Spirulina platensis as function of nitrate and NaCl concentrations. Bioresour Technol 100(5):1847–1851

Funding

This study was funded by the Akdeniz University Research Foundation (Grant number 2014.02.0121.020).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Germec, M., Cheng, KC., Karhan, M. et al. Application of mathematical models to ethanol fermentation in biofilm reactor with carob extract. Biomass Conv. Bioref. 10, 237–252 (2020). https://doi.org/10.1007/s13399-019-00425-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00425-1