Abstract

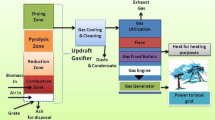

Lignocellulosic biomass is carbon neutral and produces fuels and chemicals which are used for domestic, industrial, and transportation system. Thermochemical conversion processes (combustion, gasification, and pyrolysis) are emerging technologies which have great potential for industrial implementation. In this paper, the investigation has been done to select appropriate bamboo biomass suitable for thermochemical conversion process out of 21 biomass samples available in Mizoram, India. Various characteristics considered here for the selection of the appropriate bamboo biomass include proximate analysis, ultimate analysis, and their heating values. These characteristics are plotted in different diagrams and analysed in detail. It is observed after analysis that some bamboo biomasses are suitable combustion, some are suitable for pyrolysis and rest are suitable for gasification.

Similar content being viewed by others

References

Singh H, Sapra PK, Sidhu BS (2013) Evaluation and characterization of different biomass residues through proximate & ultimate analysis and heating value. 2:6–10

S. Society, Project report on Eco-Energy solutions, (n.d.)

Kumar A, Kumar N, Baredar P, Shukla A (2015) A review on biomass energy resources, potential, conversion and policy in India. Renew Sust Energ Rev 45:530–539. https://doi.org/10.1016/j.rser.2015.02.007

Buragohain B, Mahanta P, Moholkar VS (2010) Biomass gasification for decentralized power generation: the Indian perspective. Renew Sust Energ Rev 14:73–92. https://doi.org/10.1016/j.rser.2009.07.034

Cai J, He Y, Yu X, Banks SW, Yang Y, Zhang X, Yu Y, Liu R, Bridgwater AV (2017) Review of physicochemical properties and analytical characterization of lignocellulosic biomass. 76:309–322. https://doi.org/10.1016/j.rser.2017.03.072

Liu Z, Xu A, Zhao T (2011) Energy from combustion of rice straw: status and challenges to China. 2011:325–331. https://doi.org/10.4236/epe.2011.33040

Werther J, Saenger M, Hartge E, Ogada T, Siagi Z (2000) Combustion of agricultural residues, vol 26, pp 1–27

Worley M, Yale J (2012) Biomass gasification technology assessment consolidated report biomass gasification technology assessment consolidated report

Horvat I (2018) Combustion of agricultural biomass – ISSUES AND, 1 75–86

Adhikari U, Eikeland MS, Halvorsen BM (2015) Gasification of biomass for production of syngas for biofuel:255–260. https://doi.org/10.3384/ecp15119255

Tanger P, Field JL, Jahn CE, Defoort MW, Leach JE, Allison GG (2013) Biomass for thermochemical conversion : targets and challenges. 4:1–20. https://doi.org/10.3389/fpls.2013.00218

Gillespie GD, Everard CD, Fagan CC, Mcdonnell KP (2013) Prediction of quality parameters of biomass pellets from proximate and ultimate analysis. Fuel. 111:771–777. https://doi.org/10.1016/j.fuel.2013.05.002

Vassilev SV, Vassileva CG, Vassilev VS (2015) Advantages and disadvantages of composition and properties of biomass in comparison with coal : an overview. Fuel 158:330–350. https://doi.org/10.1016/j.fuel.2015.05.050

Tinaut FV, Melgar A, Pérez JF, Horrillo A (2008) Effect of biomass particle size and air superficial velocity on the gasification process in a downdraft fixed bed gasifier. An experimental and modelling study. Fuel Process Technol 89:1076–1089. https://doi.org/10.1016/j.fuproc.2008.04.010

Ni M, Leung DYC, Leung MKH, Sumathy K (2006) An overview of hydrogen production from biomass. Fuel Process Technol 87:461–472. https://doi.org/10.1016/j.fuproc.2005.11.003

Xiao G, Ni M, Huang H, Chi Y, Xiao R, Zhong Z, Cen K (2007) Fluidized-bed pyrolysis of waste bamboo. J Zhejiang Univ Sci A 8:1495–1499. https://doi.org/10.1631/jzus.2007.A1495

Chin KL, Ibrahim S, Hakeem KR, Lee SH, Azmi M, Lila M, Bioenergy c (2017) Production from bamboo: potential source from Malaysia’s perspective, vol 12, pp 6844–6867

Salovaara J, Romero-tehuitzil H, Vaca MCM, Villamar JH (2015) Pre-operational analysis of a prototype downdraft gasifier fueled by bamboo. 62–72

A.H. Truong, Overview of bamboo biomass for energy production An Ha Truong , Thi My Anh Le to cite this version : HAL Id : halshs-01100209, (2018)

Basu P (2010 Elsevier Inc.) Biomass characteristics, first edit, ©, p 2013. https://doi.org/10.1016/B978-0-12-396488-5.00003-4

Efomah AN, Gbabo A (2015) The physical, proximate and ultimate analysis of rice husk briquettes produced from a vibratory block mould briquetting machine. 2:814–822

Obernberger I, Brunner T, Bärnthaler G (n.d.) Chemical properties of solid biofuels – significance and impact principles of solid biofuel combustion and technologies applied, pp 1–20

Bimbela F, Faria J, Ruiz MP (2015) Pyrolysis of red eucalyptus, camelina straw, and wheat straw in an ablative reactor. https://doi.org/10.1021/ef5026054

Krasznai DJ, Champagne P, Cunningham MF (2012) Bioresource technology quantitative characterization of lignocellulosic biomass using surrogate mixtures and multivariate techniques. Bioresour Technol 110:652–661. https://doi.org/10.1016/j.biortech.2012.01.089

Žecová M, Terpák J, Dor Ľ (2012) Mathematical model of gasification and combustion of biomass, 780–785

Caputo AC, Palumbo M, Pelagagge PM, Scacchia F (2005) Economics of biomass energy utilization in combustion and gasification plants: effects of logistic variables. Biomass Bioenergy 28:35–51. https://doi.org/10.1016/j.biombioe.2004.04.009

Singh RI, Brink A, Hupa M (2013) CFD modeling to study fluidized bed combustion and gasification. Appl Therm Eng 52:585–614. https://doi.org/10.1016/j.applthermaleng.2012.12.017

Ginting N (2017) Characteristics of ampel bamboo as a biomass energy source potential in Bali characteristics of Ampel bamboo as a biomass energy source potential in Bali:5–10. https://doi.org/10.1088/1757-899X/201/1/012032

Hernandez-mena LE, Pécora AAB, Beraldo AL (2014) Slow pyrolysis of bamboo biomass: analysis of biochar properties, vol 37, pp 115–120. https://doi.org/10.3303/CET1437020

Qian H, Guo X, Fan S, Hagos K, Lu X, Liu C, Huang D (2016) A simple prediction model for higher heat value of biomass. https://doi.org/10.1021/acs.jced.6b00537

Acknowledgements

We are thankful to the Advanced Research Centre for Bamboo and Rattan, Aizawl, Mizoram, India for their help in collecting different types of Bamboo available in Mizoram, India. We are also thankful to CSIR-CMERI, Durgapur for providing the lab facility for biomass analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pattanayak, S., Hauchhum, L., Loha, C. et al. Selection criteria of appropriate bamboo based biomass for thermochemical conversion process. Biomass Conv. Bioref. 10, 401–407 (2020). https://doi.org/10.1007/s13399-019-00421-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-019-00421-5