Abstract

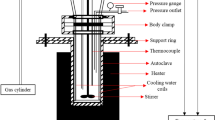

Hydrothermal liquefaction (HTL) is a promising route for producing bio-crude from various biomass feedstocks. However, high content of inorganic constituents in biomass like macroalgae Laminaria digitata and spent mushroom compost (SMC) affect the conversion process and the resulting fuel products. This research studied the effects of different acid leaching treatments on such feedstocks, subsequent HTL, and bio-crude properties. Leaching treatments were performed using five different agents: deionized water, acetic acid, citric acid, sulfuric acid, and hydrochloric acid. Performance of leaching was evaluated by analyzing both leached biomass and HTL products by elemental analysis, ash content, inductively coupled plasma (ICP) analysis, and X-ray diffraction (XRD) analysis. Catalytic and non-catalytic HTL of both feedstocks before and after treatment were performed in a 10-mL microreactor at 400 °C with a holding time of 15 min and pressures of 27–30 MPa. For macroalgae, sulfuric acid and hydrochloric acid were found the most effective in reducing the ash content from 30.42 to 20.45 and 20.87%, respectively, followed by acetic and citric acid treatment that could reduce the ash content to 21.5 and 22.15%, respectively. Similarly for SMC, citric acid and acetic acid were found the most effective in reducing the ash content from 50.34 to 37.04 and 39.94%, respectively. Citric acid did not show significant leaching of organic components such as carbohydrates and proteins and represented a less toxic and hazardous option for the leaching. The results from HTL of untreated and citric acid-treated biomass showed that the acid leaching resulted in an increase in bio-crude yields from 20.7 to 29.2% (dry ash-free basis) for macroalgae and from 22.9 to 25.1% for SMC.

Similar content being viewed by others

References

Asadieraghi M, Daud WMAW (2014) Characterization of lignocellulosic biomass thermal degradation and physiochemical structure: effects of demineralization by diverse acid solutions, energy convers. And Mgmt 82:71–82

Biller P, Ross AB (2012) Hydrothermal processing of algal biomass for the production of biofuels and chemicals. Biofuels 3:603–623

Barreiro DL, Prins W, Ronsse F, Brilman W (2013) Hydrothermal liquefaction (HTL) of microalgae for biofuel production: state of the art review and future prospects. Biomass Bioenergy 53:113–127

Villadsen SR, Dithmer L, Forsberg R, Becker J, Rudolf A, Iversen SB, Iversen BB, Glasius M (2012) Development and application of chemical analysis methods for investigation of bio-oils and aqueous phase from hydrothermal liquefaction of biomass. Energy Fuel 26:6988–6998

Toor SS, Rosendahl L, Rudolf A (2011) Hydrothermal liquefaction of biomass: a review of subcritical water technologies. Energy 36:2328–2342

Jazrawi C, Biller P, He Y, Montoya A, Ross AB, Maschmeyer T, Haynes BS (2015) Two-stage hydrothermal liquefaction of a high-protein microalga. Algal Res 8:15–22

Peterson AA, Vogel F, Lachance RP, Fröling M, Antal MJ Jr, Tester JW (2008) Thermochemical biofuel production in hydrothermal media: a review of sub-and supercritical water technologies. Energy Environ Sci 1:32–65

Y. Zhuang, J. Guo, L. Chen, D. Li, J. Liu, N. Ye, Microwave-assisted direct liquefaction of Ulvaprolifera for bio-oil production by acid catalysis, Bioresour Technol 116 (2012) 133–139

Neveux N, Yuen AK, Jazrawi C, Magnusson M, Haynes BS, Masters AF, Montoya A, Paul NA, Maschmeyer T, de Nys R (2014) Biocrude yield and productivity from the hydrothermal liquefaction of marine and fresh water green macroalgae. Bioresour Technol 155:334–341

Singh R, Bhaskar T, Balagurumurthy B (2015) Effect of solvent on the hydrothermal liquefaction of macroalgae Ulva fasciata. Process Saf Environ Prot 93:154–160

Adams JMM, Ross AB, Anastasakis K, Hodgson EM, Gallagher JA, Jones JM, Donnison IS (2011) Seasonal variation in the chemical composition of the bioenergy feedstock Laminaria digitata for thermochemical conversion. Bioresour Technol 102:226–234

Anastasakis K, Ross AB (2015) Hydrothermal liquefaction of four brown macro-algae commonly found on the UK coasts: an energetic analysis of the process and comparison with bio-chemical conversion methods. Fuel 139:546–553

Elliott DC, Hart TR, Neuenschwander GG, Rotness LJ, Roesijadi G, Zacher AH, Magnuson JK (2013) Hydrothermal processing of macroalgal feedstocks in continuous-flow reactors. ACS Sustain Chem Eng 2(2):207–215

Williams BC, McMullan JT, McCahey S (2001) An initial assessment of spent mushroom compost as a potential energy feedstock. Bioresour Technol 79(3):227–230

Eurostat, Mushrooms, energy crops, GMO: number of farms and areas by size of farm (UAA), 2005–2013 data, Tech. rep. (2016–09-15)

Bach QV, Sillero MV, Tran KQ, Skjermo J (2014) Fast hydrothermal liquefaction of a Norwegian macroalga: screening tests. Algal Res 6(Pt B):271–276

Liu X, Bi XT (2011) Removal of inorganic constituents from pine barks and switchgrass. Fuel Process Technol 92:1273–1279

Vázquez LMD, Pérez AR, Caraballo MF, Robles IV, Jena U, Das KC (2015) Demineralization of Sargassum spp. macroalgae biomass: selective hydrothermal liquefaction process for bio-oil production. Front Energy Res 3:1–11

Jenkins BM, Bakker RR, Wei JB (1996) On the properties of washed straw. Biomass Bioenergy 10(4):177–200

Turn SQ, Kinoshita CM, Ishimura DM (1997) Removal of inorganic constituents of biomass feedstocks by mechanical dewatering and leaching. Biomass Bioenergy 12(4):241–252

Jiang L, Hu S, Sun L, Su S, Xu K, He L, Xiang J (2013) Influence of different demineralization treatments on physicochemical structure and thermal degradation of biomass. Bioresour Technol 146:254–260

Fahmi R, Bridgwater A, Donnison I, Yates N, Jones JM (2008) The effect of lignin and inorganic species in biomass on pyrolysis oil yields, quality and stability. Fuel 87:1230–1240

Mourant D, Wang ZH, He M, Wang XS, Garcia-Perez M, Ling KC, Li CZ (2011) Mallee wood fast pyrolysis: effects of alkali and alkaline earth metallic species on the yield and composition of bio-oil. Fuel 90:2915–2922

Davidsson KO, Korsgren JG, Pettersson JBC, Jaglid U (2002) The effects of fuel washing techniques on alkali release from biomass. Fuel 81:137–142

Eom IY, Kim KH, Kim JY, Lee SM, Yeo HM, Choi IG, Choi JW (2011) Characterization of primary thermal degradation features of lignocellulosic biomass after removal of inorganic metals by diverse solvents. Bioresour Technol 102:3437–3444

Mayer ZA, Apfelbacher A, Hornung A (2012) Effect of sample preparation on the thermal degradation of metal-added biomass. J Anal Appl Pyrolysis 94:170–176

Fierro V, Torne-Fernandez V, Celzard A, Montane D (2007) Influence of the demineralisation on the chemical activation of Kraft lignin with orthophosphoric acid. J Hazard Mater 149:126–133

Keown DM, Hayashi JI, Li CZ (2008) Effects of volatile–char interactions on the volatilisation of alkali and alkaline earth metallic species during the pyrolysis of biomass. Fuel 87:1187–1194

Yin S, Tan Z (2012) Hydrothermal liquefaction of cellulose to bio-oil under acidic, neutral and alkaline conditions. Appl Energy 92:234–239

Li D, Chen L, Xu D, Zhang X, Ye N, Chen F, Chen S (2012) Preparation and characteristics of bio-oil from the marine brown alga Sargassum patens C. Agardh. Bioresour Technol 104:737–742

Channiwala SA, Parikh PP (2002) A unified correlation for estimating HHV of solid, liquid and gaseous fuels. Fuel 81(8):1051–1063

Knudsen JN, Jensen PA, Dam-Johansen K (2004) Transformation and release to the gas phase of Cl, K, and S during combustion of annual biomass. Energy Fuel 18:1385–1399

Patwardhan PR, Satrio JA, Brown RC, Shanks BH (2010) Influence of inorganic salts on the primary pyrolysis products of cellulose. Bioresour Technol 101:4646–4655

Feng W, van der Kooi HJ, Arons JDS (2004) Biomass conversions in subcritical and supercritical water: driving force, phase equilibria, and thermodynamic analysis. Chem Eng Process 43:1459–1467

Acknowledgements

This work is part of C3BO (Center for BioOil) at the Department of Energy Technology, Aalborg University. The research was financially supported by a grant from the Innovation Fund Denmark Grant No 1305-00030B. The authors are grateful to Patrick Biller and Maika Klemmer from the Department of Chemistry, Arhus University, for their support with some of the analysis. One of the authors, Chunbao (Charles) Xu, would also like to acknowledge the VELUX Visiting Professor Programme.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toor, S.S., Jasiunas, L., Xu, C.(. et al. Reduction of inorganics from macroalgae Laminaria digitata and spent mushroom compost (SMC) by acid leaching and selective hydrothermal liquefaction. Biomass Conv. Bioref. 8, 369–377 (2018). https://doi.org/10.1007/s13399-017-0290-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-017-0290-6