Abstract

The fabrication process of pure Cu films on an alumina substrate using a copper complex paste was evaluated. After vigorous milling for 7 h, copper complexes (copper(II) formate and pure Cu) with an average particle size of 312 nm were formed. A printed pattern was prepared with a paste containing the particles and a pure Cu film was formed by annealing at 250 °C for 30 min under nitrogen atmosphere. After removing the upper part of the film, a homogenous Cu film with a thickness of 424 nm was observed on the substrate. The film demonstrated excellent adhesion properties and had an low electrical resistivity of 4.38 μΩ cm. Hence, the film can be used as a seed for additional Cu plating.

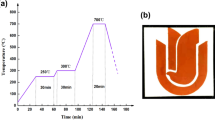

Graphical Abstract

Similar content being viewed by others

References

Rong, C., Zhang, J., Liu, C., Yang, S.: Surface metallization of alumina ceramics by pulsed high energy density plasma process. Appl. Surf. Sci. 200, 104–110 (2002)

Lim, J.D., Susan, Y.S.Y., Daniel, R.M., Leong, K.C., Wong, C.C.: Surface roughness effect on copper–alumina adhesion. Microelectron. Reliab. 53, 1548–1552 (2013)

Reboun, J., Hromadka, K., Hermansky, V., Johan, J.: Properties of power electronic substrates based on thick printed copper technology. Microelectron. Eng. 167, 58–62 (2017)

Reboun, J., Hlina, J., Totzauer, P., Hamacek, A.: Effect of copper-and silver-based films on alumina substrate electrical properties. Ceram. Int. 44, 3497–3500 (2018)

Rossnagel, S.M., Nichols, C., Hamaguchi, S., Ruzic, D., Turkot, R.: Thin, high atomic weight refractory film deposition for diffusion barrier, adhesion layer, and seed layer applications. J. Vac. Sci. Technol. B 14, 1819–1827 (1996)

Hoogvliet, J.C., Van Bennekom, W.P.: Gold thin-film electrodes: an EQCM study of the influence of chromium and titanium adhesion layers on the response. Electrochim. Acta 47, 599–611 (2001)

Yang, J.J., Strachan, J.P., Xia, Q., Ohlberg, D.A.A., Kuekes, P.J., Kelly, R.D., Stickle, W.F., Stewart, D.R., Medeiros-Ribeiro, G., Williams, R.S.: Diffusion of adhesion layer metals controls nanoscale memristive switching. Adv. Mater. 22, 4034–4038 (2010)

Najiminaini, M., Vasefi, F., Kaminska, B., Carson, J.J.L.: Optical resonance transmission properties of nano-hole arrays in a gold film: effect of adhesion layer. Opt. Express 19, 26186–26197 (2011)

Li, W., Chen, M., Wei, J., Li, W., You, C.: Synthesis and characterization of air-stable Cu nanoparticles for conductive pattern drawing directly on paper substrates. J. Nanopart. Res. 15, 1949 (2013)

Kim, Y.H., Lee, D.K., Jo, B.G., Jeong, J.H., Kang, Y.S.: Synthesis of oleate capped Cu nanoparticles by thermal decomposition. Colloids Surf. A 284, 364–368 (2006)

Xu, X., Luo, X., Zhuang, H., Li, W., Zhang, B.: Electroless silver coating on fine copper powder and its effects on oxidation resistance. Mater. Lett. 57, 3987–3991 (2003)

Yoshida, M., Tokuhisa, H., Itoh, U., Kamata, T., Sumita, I., Sekine, S.: Novel low-temperature-sintering type Cu-alloy pastes for silicon solar cells. Energy Proc. 21, 66–74 (2012)

Panek, P., Socha, R.P., Putynkowski, G., Slaoui, A.: The new copper composite of pastes for Si solar cells front electrode application. Energy Proc. 92, 962–970 (2016)

Yabuki, A., Arriffin, N., Yanase, M.: Low-temperature synthesis of copper conductive film by thermal decomposition of copper–amine complexes. Thin Solid Films 519, 6530–6533 (2011)

Yabuki, A., Tanaka, S.: Electrically conductive copper film prepared at low temperature by thermal decomposition of copper amine complexes with various amines. Mater. Res. Bull. 47, 4107–4111 (2012)

Joo, M., Lee, B., Jeong, S., Lee, M.: Laser sintering of Cu paste film printed on polyimide substrate. Appl. Surf. Sci. 258, 521–524 (2011)

Lee, B., Jeong, S., Kim, Y., Jeong, I., Woo, K., Moon, J.: Hybrid copper complex-derived conductive patterns printed on polyimide substrates. Met. Mater. Int. 18, 493–498 (2012)

Joo, M., Lee, B., Jeong, S., Lee, M.: Comparative studies on thermal and laser sintering for highly conductive Cu films printable on plastic substrate. Thin Solid Films 520, 2878–2883 (2012)

ASTM Standard D-3359-09e2: Test Methods for Measuring Adhesion by Tape Test (2009)

Turco, M., Bagnasco, G., Cammarano, C., Senese, P., Costantino, U., Sisani, M.: Cu/ZnO/Al2O3 catalysts for oxidative steam reforming of methanol: the role of Cu and the dispersing oxide matrix. Appl. Catal. B 77, 46–57 (2007)

Acknowledgements

This study was supported by the Research Program (2018-0497) funded by the SeoulTech (Seoul National University of Science and Technology).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, C.H., Lee, JH. Characterization of Copper Complex Paste: Manufacture of Thin Cu-Seed Films on Alumina Substrates. Electron. Mater. Lett. 15, 247–252 (2019). https://doi.org/10.1007/s13391-018-00117-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13391-018-00117-4