Abstract

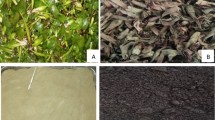

Response surface methodology based on central composite design was used as a tool to optimize the preparation of micro-/mesoporous activated carbon from plantain spike. The impact of three variables: activation temperature, activation time, and H3PO4 impregnation ratio, were evaluated on the iodine number and the methylene blue (MB) index according to the model-determined conditions. These three variables have been extensively studied using analysis of variance to assess their significance. Each response was described by a second-order regression equation showing good agreement between the predicted and the experimental data as the adjusted correlation coefficients were greater than 0.80. The multi-response optimized conditions have been set at the temperature of 480 °C, the activation time of 113 min, and the impregnation ratio of 3.34/1 (w/w). The activated carbon prepared in these conditions has a specific surface area of 896 m2/g with micro- and mesopore volumes of 34% and 66%, respectively. Water depollution capacity of this activated carbon evaluated by adsorption of MB and iodine was 206 mg/g and 927 mg/g, respectively.

Similar content being viewed by others

References

Rajoriya, S.; Bargole, S.; George, S.; Saharan, V.K.: Treatment of textile dyeing industry effluent using hydrodynamic cavitation in combination with advanced oxidation reagents. J. Hazard. Mater. 344, 1109–1115 (2018). https://doi.org/10.1016/j.jhazmat.2017.12.005

Hachi, M.; Selatnia, C.A.; Cabana, H.: Valorization of the spent biomass of pleurotus mutilus immobilized as calcium alginate biobeads for methylene blue biosorption. Environ. Process. 3, 413–430 (2016). https://doi.org/10.1007/s40710-016-0157-z

Cuiping, B.; Wenqi, G.; Dexin, F.; Mo, X.; Qi, Z.; Shaohua, C.; Zhongxue, G.; Yanshui, Z.: Natural graphite tailings as heterogeneous Fenton catalyst for the decolorization of rhodamine B. Chem. Eng. J. 197, 306–313 (2012). https://doi.org/10.1016/j.cej.2012.04.108

Nasrullah, A.; Bhat, A.H.; Naeem, A.; Isa, M.H.; Danish, M.: High surface area mesoporous activated carbon-alginate beads for efficient removal of methylene blue. Int. J. Biol. Macrom. 107, 1792–1799 (2018). https://doi.org/10.1016/j.ijbiomac.2017.10.045

Freitas, T.K.F.S.; Oliveira, V.M.; de Souza, M.T.F.; Geraldino, H.C.L.; Almeida, V.C.; Fávaro, S.L.; Garcia, J.C.: Optimization of coagulation-flocculation process for treatment of industrial textile wastewater using okra (A. esculentus) mucilage as natural coagulant. Ind. Crop. Prod. 76, 538–544 (2015). https://doi.org/10.1016/j.indcrop.2015.06.027

Hassanzadeh, E.; Farhadian, M.; Razmjou, A.; Askari, N.: An efficient wastewater treatment approach for a real woolen textile industry using a chemical assisted NF membrane process. Environ. Nanotechnol. Monit. Manag. 8, 92–96 (2017). https://doi.org/10.1016/j.enmm.2017.06.001

Orts, F.; del Río, A.I.; Molina, J.; Bonastre, J.; Cases, F.: Electrochemical treatment of real textile wastewater: Trichromy Procion HEXL®. J. Electroanal. Chem. 808, 387–394 (2018). https://doi.org/10.1016/j.jelechem.2017.06.051

Duarte, F.; Morais, V.; Maldonado-Hódar, F.J.; Madeira, L.M.: Treatment of textile effluents by the heterogeneous Fenton process in a continuous packed-bed reactor using Fe/activated carbon as catalyst. Chem. Eng. J. 232, 34–41 (2013). https://doi.org/10.1016/j.cej.2013.07.061

Ye, S.; Yan, M.; Tan, X.; Liang, J.; Zeng, G.; Wu, H.; Song, B.; Zhou, C.; Yang, Y.; Wang, H.: Facile assembled biochar-based nanocomposite with improved graphitization for efficient photocatalytic activity driven by visible light. Appl. Catal. B: Environ. 250, 78–88 (2019). https://doi.org/10.1016/j.apcatb.2019.03.004

Danish, M.; Ahmad, T.; Nadhari, W.N.A.W.; Ahmad, M.; Khanday, W.A.; Ziyang, L.; Pin, Z.: Optimization of banana trunk-activated carbon production for methylene blue-contaminated water treatment. Appl. Water. Sci. 8, 1–11 (2018). https://doi.org/10.1007/s13201-018-0644-7

Leal, T.W.; Lourenço, L.A.; Scheibe, A.S.; de Souza, S.M.A.G.U.; de Souza, A.A.U.: Textile wastewater treatment using low-cost adsorbent aiming the water reuse in dyeing process. J. Environ. Chem. Eng. 6, 2705–2712 (2018). https://doi.org/10.1016/j.jece.2018.04.008

Peláez-Cid, A.A.; Herrera-González, A.M.; Salazar-Villanueva, M.; Bautista-Hernández, A.: Elimination of textile dyes using activated carbons prepared from vegetable residues and their characterization. J. Environ. Manag. 181, 269–278 (2016). https://doi.org/10.1016/j.jenvman.2016.06.026

da Silva Lacerda, V.; López-Sotelo, J.B.; Correa-Guimarães, A.; Hernández-Navarro, S.; Sánchez-Báscones, M.; Navas-Gracia, L.M.; Martín-Ramos, P.; Martín-Gil, J.: Rhodamine B removal with activated carbons obtained from lignocellulosic waste. J. Environ. Manag. 155, 67–76 (2015). https://doi.org/10.1016/j.jenvman.2015.03.007

Bansal, R.C.; Donnet, J.B.; Stoeckli, F.: Active Carbon. Marcel Dekker, New York (1988)

Das, S.; Mishra, S.: Box-Behnken statistical design to optimize preparation of activated carbon from limonia acidissima shell with desirability approach. J. Environ. Chem. Eng. 5, 588–600 (2016). https://doi.org/10.1016/j.jece.2016.12.034

Sayğili, H.; Güzel, F.: High surface area mesoporous activated carbon from tomato processing solid waste by zinc chloride activation: Process optimization, characterization and dyes adsorption. J. Clean. Prod. 113, 995–1004 (2016). https://doi.org/10.1016/j.jclepro.2015.12.055

Abdel-Ghani, N.T.; El-Chaghaby, G.A.; Elgammal, M.H.; Rawash, E.S.A.: Optimizing the preparation conditions of activated carbons from olive cake using KOH activation. New Carbon Mater. 31, 492–500 (2016). https://doi.org/10.1016/S1872-5805(16)60027-6

Def, T.; Traoré, S.; Aby, N.; Gnonhouri, P.; Yao, N.; Kobenan, K.; Konan, E.; Adiko, A.; Zakra, N.: Diversité et sélection participative de variétés locales productives de banane plantain de Côte d’Ivoire. J. Appl. Biosci. 114, 11324–11335 (2017). https://doi.org/10.4314/jab.v114i1.6

Sugumaran, P.; Susan, V.P.; Ravichandran, P.; Seshadri, S.: Production and characterization of activated carbon from banana empty fruit bunch and Delonix regia fruit pod. J. Sustain. Energ. Environ. 3, 125–132 (2012)

Ahmad, A.A.; Hameed, B.H.: Effect of preparation conditions of activated carbon from bamboo waste for real textile wastewater. J. Hazard. Mater. 173, 487–493 (2010). https://doi.org/10.1016/j.jhazmat.2009.08.111

Dizbay-Onat, M.; Vaidya, U.K.; Lungu, C.T.: Preparation of industrial sisal fiber waste derived activated carbon by chemical activation and effects of carbonization parameters on surface characteristics. Ind. Crop. Prod. 95, 583–590 (2016). https://doi.org/10.1016/j.indcrop.2016.11.016

Kan, Y.; Yue, Q.; Li, D.; Wu, Y.; Gao, B.: Preparation and characterization of activated carbons from waste tea by H3PO4 activation in different atmospheres for oxytetracycline removal. J. Taiwan Inst. Chem. Eng. 71, 494–500 (2017). https://doi.org/10.1016/j.jtice.2016.12.012

Huang, Y.P.; Hou, C.H.; Hsi, H.C.; Wu, J.W.: Optimization of highly microporous activated carbon preparation from Moso bamboo using central composite design approach. J. Taiwan Inst. Chem. Eng. 50, 266–275 (2015). https://doi.org/10.1016/j.jtice.2014.12.019

Yang, J.; Qiu, K.: Experimental design to optimize the preparation of activated carbons from herb residues by vacuum and traditional ZnCl2 chemical activation. Ind. Eng. Chem. Res. 50, 4057–4064 (2011). https://doi.org/10.1021/ie101531p

Senthilkumar, T.; Chattopadhyay, S.K.; Miranda, L.R.: Optimization of activated carbon preparation from pomegranate peel (Punica granatum Peel) using RSM. Chem. Eng. Commun. 204, 238–248 (2017). https://doi.org/10.1080/00986445.2016.1262358

Juang, R.S.; Tseng, R.L.; Wu, F.C.: Role of microporosity of activated carbons on their adsorption abilities for phenols and dyes. Adsorption. 7, 65–72 (2001). https://doi.org/10.1023/A:1011225001324

Ennaciri, K.; Baçaoui, A.; Sergent, M.; Yaacoubi, A.: Application of fractional factorial and Doehlert designs for optimizing the preparation of activated carbons from Argan shells. Chemometr. Intell. Lab. 139, 48–57 (2014). https://doi.org/10.1016/j.chemolab.2014.09.006

Tounsadi, H.; Khalidi, A.; Abdennouri, M.; Barka, N.: Activated carbon from Diplotaxis Harra biomass: optimization of preparation conditions and heavy metal removal. J. Taiwan Inst. Chem. Eng. 59, 348–358 (2016). https://doi.org/10.1016/j.jtice.2015.08.014

Lussier, M.G.; Shull, J.C.; Miller, D.J.: Activated carbon from cherry stones. Carbon 32, 1493–1498 (1994). https://doi.org/10.1016/0008-6223(94)90144-9

Warhurst, A.M.; McConnachie, G.L.; Pollard, S.J.T.: The production of activated carbon for water treatment in Malawi from the waste seed husks of Moringa oleifera. Water. Sci. Technol. 34, 177–184 (1996). https://doi.org/10.1016/S0273-1223(96)00836-0

Raposo, F.; Rubia, M.A.D.L.; Borja, R.: Methylene blue number as useful indicator to evaluate the adsorptive capacity of granular activated carbon in batch mode: Influence of adsorbate/adsorbent mass ratio and particle size. J. Hazard. Mater. 165, 291–299 (2009). https://doi.org/10.1016/j.jhazmat.2008.09.106

Garba, Z.N.; Rahim, A.A.; Bello, B.Z.: Optimization of preparation conditions for activated carbon from Brachystegia eurycoma seed hulls: a new precursor using central composite design. J. Environ. Chem. Eng. 3, 2892–2899 (2015). https://doi.org/10.1016/j.jece.2015.10.017

Thuan, T.V.; Quynh, B.T.P.; Nguyen, T.D.; Ho, V.T.T.; Bach, L.G.: Response surface methodology approach for optimization of Cu2+, Ni2+ and Pb2+ adsorption using KOH-activated carbon from banana peel. Surf. Interfaces. 6, 209–217 (2017). https://doi.org/10.1016/j.surfin.2016.10.007

Torrades, F.; Saiz, S.; García-Hortal, J.A.: Using central composite experimental design to optimize the degradation of black liquor by Fenton reagent. Desalination 268, 97–102 (2011). https://doi.org/10.1016/j.desal.2010.10.003

Domínguez, J.R.; González, T.; Palo, P.; Cuerda-Correa, E.M.: Fenton + Fenton-like integrated process for carbamazepine degradation: optimizing the system. Ind. Eng. Chem. Res. 51, 2531–2538 (2012). https://doi.org/10.1021/ie201980p

Kaneko, K.; Ishii, C.: Superhigh surface area determination of microporous solids. Colloids Surf. 67, 203–212 (1992). https://doi.org/10.1016/0166-6622(92)80299-H

Gregg, S.J.; Sing, K.S.W.: Adsorption, Surface Area, and Porosity. Academic Press, London (1982)

Jagiello, J.; Olivier, J.P.: A simple two-dimensional NLDFT model of gas adsorption in finite carbon pores. Application to pore structure analysis. J. Phys. Chem. C. 113, 19382–19385 (2009). https://doi.org/10.1021/jp9082147

Seung Kim, Y.; Rae Park, C.: Titration Method for the Identification of Surface Functional Groups. Tsinghua University Press Limited (2016). https://doi.org/10.1016/b978-0-12-805256-3.00013-1

Brahmi, L.; Kaouah, F.; Boumaza, S.; Trari, M.: Response surface methodology for the optimization of acid dye adsorption onto activated carbon prepared from wild date stones. Appl. Water. Sci. 9, 1–13 (2019). https://doi.org/10.1007/s13201-019-1053-2

Rondina, D.J.G.; Ymbong, D.V.; Cadutdut, M.J.M.; Nalasa, J.R.S.; Paradero, J.B.; Mabayo, V.I.F.; Arazo, R.O.: Utilization of a novel activated carbon adsorbent from press mud of sugarcane industry for the optimized removal of methyl orange dye in aqueous solution. Appl. Water. Sci. 9, 1–12 (2019). https://doi.org/10.1007/s13201-019-1063-0

Unuabonah, E.I.; Adie, G.U.; Onah, L.O.; Adeyemi, O.G.: Multistage optimization of the adsorption of methylene blue dye onto defatted Carica papaya seeds. Chem. Eng. J. 155, 567–579 (2009). https://doi.org/10.1016/j.cej.2009.07.012

Sapkaite, I.; Barrado, E.; Fdz-Polanco, F.; Pérez-Elvira, S.I.: Optimization of a thermal hydrolysis process for sludge pre-treatment. J. Environ. Manag. 192, 25–30 (2017). https://doi.org/10.1016/j.jenvman.2017.01.043

Briton, B.G.H.; Duclaux, L.; Richardson, Y.; Yao, K.B.; Reinert, L.; Soneda, Y.: Optimization of total organic carbon removal of a real dyeing wastewater by heterogeneous Fenton using response surface methodology. Desal. Water. Treat. 136, 186–198 (2018). https://doi.org/10.5004/dwt.2018.22845

Prahas, D.; Kartika, Y.; Indraswati, N.; Ismadji, S.: Activated carbon from jackfruit peel waste by H3PO4 chemical activation: Pore structure and surface chemistry characterization. Chem. Eng. J. 140, 32–42 (2008). https://doi.org/10.1016/j.cej.2007.08.032

Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.S.; Rouquerol, J.; Siemieniewska, T.: International Union of Pure Commission on Colloid and Surface Chemistry Including Catalysis, Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure Appl. Chem. 57, 603–619 (1985). https://doi.org/10.1351/pac198557040603

Jagtoyen, M.; Derbyshire, F.: Activated carbons from yellow poplar and white oak by H3PO4 activation. Carbon 36, 1085–1097 (1998). https://doi.org/10.1016/S0008-6223(98)00082-7

Zuim, D.R.; Carpiné, D.; Distler, G.A.R.; De Paula Scheer, A.; Igarashi-Mafra, L.; Mafra, M.R.: Adsorption of two coffee aromas from synthetic aqueous solution onto granular activated carbon derived from coconut husks. J. Food Eng. 104, 284–292 (2011). https://doi.org/10.1016/j.jfoodeng.2010.12.019

Mahmood, T.; Ali, R.; Naeem, A.; Hamayun, M.; Aslam, M.: Potential of used Camellia sinensis leaves as precursor for activated carbon preparation by chemical activation with H3PO4; optimization using response surface methodology. Process. Saf. Environ. Prot. 109, 548–563 (2017). https://doi.org/10.1016/j.psep.2017.04.024

Silva, T.L.; Cazetta, A.L.; Souza, P.S.C.; Zhang, T.; Asefa, T.; Almeida, V.C.: Mesoporous activated carbon fibers synthesized from denim fabric waste: Efficient adsorbents for removal of textile dye from aqueous solutions. J. Clean. Prod. 171, 482–490 (2018). https://doi.org/10.1016/j.jclepro.2017.10.034

Konan, A.T.S.; Richard, R.; Andriantsiferana, C.; Yao, K.B.; Manero, M.H.: Low-cost activated carbon for adsorption and heterogeneous ozonation of phenolic wastewater. Desal. Water. Treat. 163, 336–346 (2019). https://doi.org/10.5004/dwt.2019.24479

Gueye, M.; Richardson, Y.; Kafack, F.T.; Blin, J.: High efficiency activated carbons from African biomass residues for the removal of chromium(VI) from wastewater. J. Environ. Chem. Eng. 2, 273–281 (2014). https://doi.org/10.1016/j.jece.2013.12.014

Charola, S.; Patel, H.; Chandna, S.; Maiti, S.: Optimization to prepare porous carbon from mustard husk using response surface methodology adopted with central composite design. J. Clean. Prod. 223, 969–979 (2019). https://doi.org/10.1016/j.jclepro.2019.03.169

Üner, O.; Geçgel, Ü.; Kolancilar, H.; Bayrak, Y.: Adsorptive removal of rhodamine B with activated carbon obtained from okra wastes. Chem. Eng. Commun. 204, 772–783 (2017). https://doi.org/10.1080/00986445.2017.1319361

Lu, P.J.; Lin, H.C.; Te Yu, W.; Chern, J.M.: Chemical regeneration of activated carbon used for dye adsorption. J. Taiwan Inst. Chem. Eng. 42, 305–311 (2011). https://doi.org/10.1016/j.jtice.2010.06.001

Acknowledgments

The authors thank the French Embassy in Côte d'Ivoire via Campus-France and the “Agence Universitaire de la Francophonie” for awarding the Ph.D scholarship to Bi Gouessé Henri Briton.

Funding

No funding was received for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

The authors certify that article is original work that has not been published elsewhere and approve the submission to Arabian journal for Science and Engineering.

Informed consent

All authors have endorsed the publication of this research.

Rights and permissions

About this article

Cite this article

Briton, B.G.H., Yao, B.K., Richardson, Y. et al. Optimization by Using Response Surface Methodology of the Preparation from Plantain Spike of a Micro-/Mesoporous Activated Carbon Designed for Removal of Dyes in Aqueous Solution. Arab J Sci Eng 45, 7231–7245 (2020). https://doi.org/10.1007/s13369-020-04390-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04390-0