Abstract

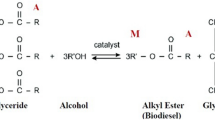

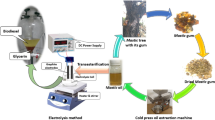

Transesterification of crude cottonseed oil with methanol in the presence of catalyst (NaOH) in tubular microreactor has been investigated experimentally. The transesterification reaction was performed in a silicon tube of 0.8 mm inner diameter, mounted in serpentine manner configuration on an acrylic sheet. Influence of process variables such as reaction temperature \((35{-}45\,{^{\circ }}\hbox {C})\), NaOH concentration (0.5–1.5 wt%) and oil/methanol molar ratio (1:7–1:9) on fatty acid methyl ester (FAME) was studied. In order to further improve biodiesel yield, an experimental design was employed using the Box–Behnken method and analysis of variance. The %FAME was calculated by gas chromatography using methyl arachidate as an internal standard. Fourier transform infrared spectroscopy was used to investigate the functional groups present in biodiesel. Thermal stability of biodiesel was evaluated using a thermogravimetric analyser. The optimal condition found was oil/methanol molar ratio (1:8), catalyst concentration (1 wt%) and reaction temperature \((45\,{^{\circ }}\hbox {C})\) while %FAME yield of about 94.1% at a residence time of 90 s.

Similar content being viewed by others

References

Abdullah, A.Z.; Salamatinia, B.; Mootabadi, H.; Bhatia, S.: Current status and policies on biodiesel industry in Malaysia as the world’s leading producer of palm oil. Energy Policy 37(12), 5440–5448 (2009)

Wang, R.; Zhou, W.W.; Hanna, M.A.; Zhang, Y.P.; Bhadury, P.S.; Wang, Y.; Song, B.A.; Yang, S.: Biodiesel preparation, optimization, and fuel properties from non-edible feedstock, Datura stramonium L. Fuel 91(1), 182–186 (2012)

Yücel, Y.: Optimization of biocatalytic biodiesel production from pomace oil using response surface methodology. Fuel Process. Technol. 99, 97–102 (2012)

Fukuda, H.; Kond, A.; Noda, H.: Biodiesel fuel production by transesterification. J. Biosci. Bioeng. 92(5), 405–416 (2001)

Leung, D.Y.C.; Wu, X.; Leung, M.K.H.: A review on biodiesel production using catalyzed transesterification. Appl. Energy 87(4), 1083–1095 (2010)

Marchetti, J.M.; Miguel, V.U.; Errazu, A.F.: Techno-economic study of different alternatives for biodiesel production. Fuel Process. Technol. 89(8), 740–748 (2008)

Sarin, R.; Sharma, M.; Sinharay, S.; Malhotra, R.K.: Jatropha–palm biodiesel blends: an optimum mix for Asia. Fuel 86(10–11), 1365–1371 (2007)

Šalić, A.; Zelić, B.: Microreactors-portable factories for biodiesel fuel production. Goriva Maz. 50(2), 85–110 (2011)

Campanelli, P.; Banchero, M.; Manna, L.: Synthesis of biodiesel from edible, non-edible and waste cooking oils via supercritical methyl acetate transesterification. Fuel 89(12), 3675–3682 (2010)

Yao, X.; Zhang, Y.; Du, L.; Liu, J.; Yao, J.: Review of the applications of microreactors. Renew. Sustain. Energy Rev. 47, 519–539 (2015)

Rashid, W.N.W.A.; Uemura, Y.; Kusakabe, K.; Osman, N.B.; Abdullah, B.: Synthesis of biodiesel from palm oil in capillary millichannel reactor: effect of temperature, methanol to oil molar ratio, and KOH concentration on FAME yield. Proc. Chem. 9, 165–171 (2014)

Chang, C.H.; Paul, B.K.; Remcho, V.T.; Atre, S.; Hutchison, J.E.: Synthesis and post-processing of nanomaterials using microreaction technology. J. Nanopart. Res. 10(6), 965–980 (2008)

Lin, L.; Ying, D.; Chaitep, S.; Vittayapadung, S.: Biodiesel production from crude rice bran oil and properties as fuel. Appl. Energy 86(5), 681–688 (2009)

Patil, P.D.; Deng, S.: Optimization of biodiesel production from edible and non-edible vegetable oils. Fuel 88(7), 1302–1306 (2009)

Billo, R.E.; Oliver, C.R.; Charoenwat, R.; Dennis, B.H.; Wilson, P.A.; Priest, J.W.; Beardsley, H.: A cellular manufacturing process for a full-scale biodiesel microreactor. J. Manuf. Syst. 37, 409–416 (2015)

Canter, N.: Making biodiesel in a microreactor. Tribol. Lubr. Technol. 68(8), 15–17 (2006)

Jovanovic, G.N.; Paul, B.K.; Parker, J.; Al-Dhubabian, A.: United States Patent Application, July 2, 2009. US 165,366, A1 (2009)

Ariharan, V.N.; Devi, V.N.M.; Prasad, P.N.: Physico-chemical characterization of cotton seed oil for its potential use as biodiesel. Res. J. Pharm. Biol. Chem. Sci. 4(2), 1336–1345 (2013)

Knothe, G.; Van Gerpen, J.; Krahl, J.: The Biodiesel Handbook. AOCS Press, Champaign, IL (2005)

Deshmukh, R.K.; Naik, J.B.: Optimization of sustained release aceclofenac microspheres using response surface methodology. Mater. Sci. Eng. C 48, 197–204 (2015)

Khairnar, G.; Mokale, V.; Naik, J.: Formulation and development of nateglinide loaded sustained release ethyl cellulose microspheres by \(O/W\) solvent emulsification technique. J. Pharm. Investig. 44(6), 411–422 (2014)

Yadava, S.K.; Naik, J.B.; Patil, J.S.; Mokale, V.J.; Singh, R.: Enhanced solubility and bioavailability of lovastatin using stabilized form of self-emulsifying drug delivery system. Colloids Surf. A Physicochem. Eng. Asp. 481, 63–71 (2015)

Patil, P.; Khairnar, G.; Naik, J.: Preparation and statistical optimization of Losartan Potassium loaded nanoparticles using Box Behnken factorial design: microreactor precipitation. Chem. Eng. Res. Des. 104, 98–109 (2015)

McCurry, J.D.: GC analysis of total fatty acid methyl esters (FAME) and methyl linolenate in biodiesel using the revised EN14103 : 2011 Method. Agilent Technologies, pp. 1–6 (2011)

Wang, Y.; Ou, S.; Liu, P.; Xue, F.; Tang, S.: Comparison of two different processes to synthesize biodiesel by waste cooking oil. J. Mol. Catal. A: Chem. 252(1–2), 107–112 (2006)

Patil, J.S.; Patil, P.B.; Sonawane, P.; Naik, J.B.: Design and development of sustained-release glyburide-loaded silica nanoparticles. Bull. Mater. Sci. 40(2), 263–270 (2017)

Rahimi, M.; Aghel, B.; Alitabar, M.; Sepahvand, A.; Ghasempour, H.R.: Optimization of biodiesel production from soybean oil in a microreactor. Energy Convers. Manag. 79, 599–605 (2014)

Sun, J.; Ju, J.; Ji, L.; Zhang, L.; Xu, N.: Synthesis of biodiesel in capillary microreactors. Ind. Eng. Chem. Res. 47(5), 1398–1403 (2008)

Basiri, M.; Rahimi, M.; Mohammadi, H.B.: Ultrasound-assisted biodiesel production in microreactors. Iran. J. Chem. Eng. 13(2), 22–32 (2016)

American Society of Testing and Materials Standard Methods Annual Book of ASTM for Biodiesel Specification, Philadelphia (2002)

Patil, P.; Gaikwad, G.; Patil, D.R.; Naik, J.: Synthesis of 1-D ZnO nanorods and polypyrrole/1-D ZnO nanocomposites for photocatalysis and gas sensor applications. Bull. Mater. Sci. 39(3), 655–665 (2016)

Sood, S.; Jain, K.; Gowthamarajan, K.: Optimization of curcumin nanoemulsion for intranasal delivery using design of experiment and its toxicity assessment. Colloids Surf. B Biointerfaces 113, 330–337 (2014)

Mustapha, M.; Haruna, M.K.; Awwal, S.; Ibrahim, A.: Optimization of biodiesel production from crude cotton seed oil using central composite design. Am. J. Chem. Biochem. Eng. 1(1), 8–14 (2016)

Hossain, A.B.M.S.; Mazen, M.A.: Effects of catalyst types and concentrations on biodiesel production from waste soybean oil biomass as renewable energy and environmental recycling process. Aust. J. Crop Sci. 4(7), 550–555 (2010)

Onukwuli, D.O.; Emembolu, L.N.; Ude, C.N.; Aliozo, S.O.; Menkiti, M.C.: Optimization of biodiesel production from refined cotton seed oil and its characterization. Egypt. J. Pet. 26(1), 103–110 (2017)

Jain, S.; Sharma, M.P.: Application of thermogravimetric analysis for thermal stability of Jatropha curcas biodiesel. Fuel 93, 252–257 (2012)

Freire, L.M.S.; Bicudo, T.C.; Rosenhaim, R.; Sinfrônio, F.S.M.; Botelho, J.R.; Carvalho Filho, J.R.; Santos, I.M.G.; Fernandes, V.J.; Antoniosi Filho, N.R.; Souza, A.G.: Thermal investigation of oil and biodiesel from Jatropha curcas L. J. Therm. Anal. Calorim. 96(3), 1029–1033 (2009)

Acknowledgements

Authors are grateful to Technical Education Quality Improvement Program (TEQIP-II), World Bank and MHRD, New Delhi, for providing financial assistance to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shrimal, P., Sanklecha, H., Patil, P. et al. Biodiesel Production in Tubular Microreactor: Optimization by Response Surface Methodology. Arab J Sci Eng 43, 6133–6141 (2018). https://doi.org/10.1007/s13369-018-3245-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3245-8