Abstract

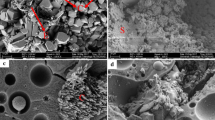

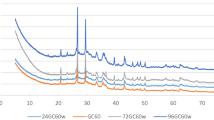

Acidizing is a widely used technique to stimulate an oil well in order to enhance its production. When portland cement is placed in contact with acid fluids, it will dissolve and, at some time, will be fully degraded because the acids have reacted with calcium silicate hydrate which resulted in the breaking up of the cement intergranular structure. This in turn will give rise to well integrity issue. Instead of introducing a new acid type, which may not be as effective toward reservoir formation, researchers have come up with a new cementing material, namely geopolymer cement. Literature has shown that geopolymer cement is unreactive toward conventional acids. In addition, its strength may be improved by introducing Nano-silica in the admixture. However, the studies were conducted at ambient condition. The objective of this work is to investigate geopolymerization mechanism and microstructure behavior of fly ash-based geopolymer cement with Nano-silica admixture. Two cement slurries, geopolymer and Class G OPC, were prepared in accordance with API RP-10B. The slurries were cured for 24 h at 130 \({^{\circ }}\)C and 20.69 MPa at the HPHT curing chamber before being exposed to 15 wt% acid solution for 14 days. The reaction mechanism of the cement samples was investigated by using FTIR and XRD analyses. The results were further validated by carrying out SEM and EDS tests to evaluate the microstructure behavior and chemical compositions of the cured samples. Results show that fly ash-based geopolymer cement with 1 wt% of Nano-silica additive was the least affected cement samples after acid treatment as compared to a similar weight of Class G OPC.

Similar content being viewed by others

References

Agapiou, K.; Charpiot, S.: Cement and wellbore integrity. Int. Cem. Rev.: Oilw. Cem., 113-116 (2013)

Choi, Y.S.; Young, D.; Nesic, S.; Gray, L.G.S.: Wellbore integrity and corrosion of carbon steel in \(\text{ CO }_{2}\) geologic storage environment: a literature review. Int. J. Greenh. Gas Control 16, S70–S77 (2013)

Nasvi, C.M.; Ranjith, P.G.; Sanjavan, J.: Geopolymer as well cement and variation of its mechanical properties under different curing temperature and curing mediums. Greenh. Gases Sci. Technol. 2(1), 46–58 (2012)

Izzat, A.M.; Abdullah, M.; Hussin, K.; Sandu, A.V.; Ghazali, C.M.R.; Mohd Tahir, M.F.; Ligia, M.M.: Sulfuric acid attack on ordinary portland cement and geopolymer material. Rev. Chim. (Bucharest) 64(9), 1011–1014 (2013)

Bensted, J.: Class G and H basic oilwell cements. World Cem., pp 44–50 (1992).

Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S.: The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 47, 409–418 (2013)

Adak, D.; Sarkar, M.; Mandal, S.: Effect of nano-silica on strength and durability of fly ash based geopolymer mortar. Constr. Build. Mater. 70, 453–459 (2014)

Maheswaran, S.: Study on effect of low calcium fly ash on geopolymer cement for oil well cementing. In: Paper SPE 176454 Presented at the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Bali, Indonesia, 20–22 October (2015). https://doi.org/10.2118/176454-MS.

Mahmoudkhani, A.H.; Huynh, D.; Sylvestre, C.J.; Schneider, J.: New environment- friendly cement slurries with enhanced mechanical properties for gas well cementing. In: Paper SPE 115004 Presented at the CIPC/SPE Gas Technology Symposium 2008 Joint Conference, Calgary, Alberta, Canada, 16–19 (2008). https://doi.org/10.2118/115004-MS.

Bakharev, T.: Geopolymeric materials prepared using class F fly ash and elevated temperature curing. Cem. Concr. Res. 35(6), 1224–1232 (2005)

Srivinasan, K.; Sivakumar, A.: Geopolymer binders: a need for future concrete construction. ISRN Polymer Sci. 2013, Article ID 509185 (2013). https://doi.org/10.1155/2013/509185.

Ridha, S.; Yerikania, U.: New nano-geopolymer cement system improves wellbore integrity upon acidizing job: Experimental findings. In: Paper SPE 176419 Presented at the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Nusa Dua, Bali, Indonesia, 20–22 October (2015). https://doi.org/10.2118/176419-MS.

Davidovits, J.: Properties of geopolymer cement. Alkaline Cem. Concr., 131–149 (1994)

Salehi. S.; Khattak, M.J.; Ali, N.; Rizvi, H.R.: Development of geopolymer-based cement slurries with enhanced thickening time, compressive and shear bond strength and durability. In: Paper SPE 178793 Presented at the IADC/SPE Drilling Conference and Exhibition, Fort Worth, Texas,USA, 1–3 March (2016). https://doi.org/10.2118/178793-MS.

Hewayde, E.; Nehdi, M.; Allouche, E.; Nakhla, G.: Effect of geopolymer cement on microstructure, compressive strength and sulfuric acid resistance of concrete. Mag. Concr. Res. 58(5), 321–33 (2006)

Santra, A.; Boul, P.J.; Pang, X.: Influence of nanomaterials in oilwell cement hydration and mechanical properties. In: Paper SPE 156937 Presented at the SPE International Oilfield Nanotechnology Conference, Noorwijk, The Netherlands, 12–14 June (2012). https://doi.org/10.2118/156937-MS.

Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J.: Geopolymer technology: the current state of the art. J. Mater. Sci. 42(9), 2917–2933 (2007)

Davidovits, J.: Geopolymer Chemistry and Applications, 3rd edn. Institute Geopolymer, Saint-Quentin (2011)

Houseworth, J.: Advanced Well Stimulation Technologies in California Chapter 2, p. 61. CCST Publication, Sacramento (2016)

Stegent, N.A.; Wagner, A.L.; Mullen, J.; Borstmayer, R.E.: Engineering a successful fracture-stimulation treatment in the eagle ford shale. In: Paper SPE 136183 Presented at the SPE Tight Gas Completions Conference, San Antonio, Texas, USA, 2–3 November 2010. https://doi.org/10.2118/136183-MS.

A. C 109/C 109M – 07: Standard test method for compressive strength of hydraulic cement mortars (using 2-in. or [50-mm] cube specimens). ASTM International (2008)

Syed, T.: EPA Hydraulic Fracturing Workshop, 2011. Retrieved December 22, 2017, from https://www.epa.gov/sites/production/files/documents/cementingandzonalisolationforhfwells.pdf

Bakharev, T.: Resistance of geopolymer materials to acid attack. Cem. Concr. Res. 35, 658–670 (2005)

Hughes, T.L.; Methven, C.M.; Jones, T.G.J.; Pelham, S.E.; Fletcher, P.; Hall, C.: Determining cement composition by Fourier Transform Infrared Spectroscopy. Adv. Cem. Based Mater. 2, 91–104 (1995)

Acknowledgements

The authors wish to express their gratitude to Universiti Teknologi PETRONAS for providing laboratory facilities and research fund under the Fundamental Research Grant Scheme (FRGS) Project No. 0153AB-K96.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ridha, S., Hamid, A.I.A., Setiawan, R.A. et al. Microstructure Behavior of Fly Ash-Based Geopolymer Cement Exposed to Acidic Environment for Oil Well Cementing. Arab J Sci Eng 43, 6413–6428 (2018). https://doi.org/10.1007/s13369-018-3183-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3183-5