Abstract

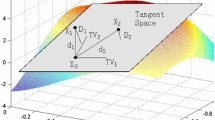

This paper proposes a new manifold learning-based scheme for multi-fault detection and classification, which utilizes local and nonlocal embedding method to build a statistic index for fault detection and subsequently develops a joint global and local discriminant embedding (GLDE) approach to discover the discriminant features of multiple faults for fault classification. The proposed GLDE approach can capture the global and local/nonlocal structure information of complicated data and obtain the concise discriminant information for classification. Compared with the conventional Fisher discriminant analysis method, GLDE has a strong discriminant power and provides better monitoring results for complex multi-fault Tennessee Eastman process.

Similar content being viewed by others

References

Ge, Z.; Song, Z.H.; Gao, F.: Review of recent research on data-based process monitoring. Ind. Eng. Chem. Res. 52(l0), 3543–3562 (2013)

Chiang, L.H.; Russell, E.; Braatz, R.D.: Fault Detection and Diagnosis in Industrial Systems. Springer, Berlin (2001)

AlGhazzawi, A.; Lennox, B.: Monitoring a complex refining process using multivariate statistics. Control Eng. Pract. 16, 294–307 (2008)

Qin, S.J.: Survey on data-driven industrial process monitoring and diagnosis. Annu. Rev. Control 36(2), 220–234 (2012)

Fan, Y.P.; Li, S.P.; Zhang, Y.W.: Monitoring of multimode processes based on quality-related common subspace separation. Math. Probl. Eng. 2014, 1–8 (2014)

Nomikos, P.; MacGregor, J.F.: Monitoring of batch processes using multi-way principal component analysis. AIChE J. 40, 1361–1375 (1994)

Kourti, T.; MacGregor, J.F.: Multivariate SPC methods for process and product monitoring. J. Qual. Technol. 28(4), 409–428 (1996)

Choi, S.; Lee, I.B.: Nonlinear dynamic process monitoring based on dynamic kernel PCA. Chem. Eng. Sci. 59(24), 5897–5908 (2004)

Jiang, X.D.; Zhao, H.T.; Jin, B.: Multimode process monitoring based on sparse principal component selection and Bayesian inference-based probability. Math. Probl. Eng. 2015, 1–12 (2015)

MacGregor, J.F.; Jaeckle, C.; Kiparissides, C.; Koutoudi, M.: Process monitoring and diagnosis by multiblock PLS methods. AIChE J. 40(5), 826–838 (1994)

Kruger, U.; Dimitriadis, G.: Diagnosis of process faults in chemical systems using a local partial least squares approach. AIChE J. 54(10), 2581–2596 (2008)

Muradore, R.; Fiorini, P.: A PLS-based statistical approach for fault detection and isolation of robotic manipulators. IEEE Trans. Ind. Electron. 59(8), 3167–3175 (2012)

Duda, R.O.; Hart, P.E.; Stork, D.G.: Pattern Classification. Wiley, New York (2001)

Chiang, L.; Kotanchek, M.; Kordon, A.: Fault diagnosis based on Fisher discriminant analysis and support vector machines. Comput. Chem. Eng. 28(8), 1389–1401 (2004)

Yu, J.: Localized Fisher discriminant analysis based complex chemical process monitoring. AIChE J. 57(7), 1817–1828 (2011)

He, X.F.; Niyogi, P.: Locality preserving projections. In: Proceedings of the Conference on Advances in Neural Information Processing Systems, Dec 8–13, Vancouver, Canada (2003)

Tenenbaum, J.B.; Silva, V.; Langford, J.C.: A global geometric framework for nonlinear dimensionality reduction. Science 290(5500), 2319–2323 (2000)

Belkin, M.; Niyogi, P.: Laplacian eigenmaps and spectral techniques for embedding and clustering. Neural Inf. Process. Syst. 1, 585–592 (2002)

Lu, C.H.; Xiao, S.Q.; Gu, X.F.: Hyperplane distance neighbor clustering based on local discriminant analysis for complex chemical processes monitoring. Korean J. Chem. Eng. 31(11), 1943–1953 (2014)

Song, B.; Ma, Y.X.; Shi, H.B.: Multimode process monitoring using improved dynamic neighborhood preserving embedding. Chemom. Intell. Lab. Syst. 135, 17–30 (2014)

Ma, Y.X.; Song, B.; Shi, H.B.; Yang, Y.W.: Fault detection via local and nonlocal embedding. Chem. Eng. Res. Des. 94, 538–548 (2015)

Zhang, D.; He, J.Z.; Zhao, Y.; Luo, Z.L.; Du, M.H.: Global plus local: a complete framework for feature extraction and recognition. Pattern Recogn. 47(3), 1433–1442 (2014)

Zhang, M.G.; Ge, Z.Q.; Song, Z.H.; Fu, R.: Global-local structure analysis model and its application for fault detection and identification. Ind. Eng. Chem. Res. 50(11), 6387–6848 (2011)

Yu, J.B.: Local and global principal component analysis for process monitoring. J. Process Control 22(7), 1358–1373 (2012)

Luo, L.J.: Process monitoring with global-local preserving projections. Ind. Eng. Chem. Res. 53(18), 7696–7705 (2014)

Luo, L.J.; Bao, S.Y.; Mao, J.F.; Tang, D.: Nonlinear process monitoring based on kernel global-local preserving projections. J. Process Control 38, 11–21 (2016)

Qin, S.J.: Statistical process monitoring: basics and beyond. J. Chemom. 17(8–9), 480–502 (2003)

Martin, E.B.; Morris, A.J.: Non-parametric confidence bounds for process performance monitoring charts. J. Process Control 6(6), 349–358 (1996)

Downs, J.J.; Vogel, E.F.: Plant-wide industrial process control problem. Comput. Chem. Eng. 17(3), 245–255 (1993)

Ricker, N.L.: Decentralized control of the Tennessee Eastman challenge process. J. Process Control 6(4), 205–221 (1996)

Ricker, N.L.: Optimal steady-state operation of the Tennessee Eastman challenge process. Comput. Chem. Eng. 19(9), 949–959 (1995)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Additional information

The work is supported by Research Fund of Nantong (MS12016036) and University Research Fund of Jiangsu Province (17KJB530008).

Rights and permissions

About this article

Cite this article

Lu, C., Wang, J. Joint Global and Local Discriminant Embedding for Multi-fault Process Monitoring and Fault Classification. Arab J Sci Eng 43, 5859–5869 (2018). https://doi.org/10.1007/s13369-018-3072-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3072-y