Abstract

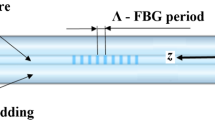

This paper details some significant findings on the use of the fiber Bragg grating (FBG) sensors for structural health monitoring (SHM) in aerospace fiber reinforced polymer (FRP) structures. A diminutive sensor provides a capability of imbedding inside FRP structures to monitor vital locations of damage. Some practical problems associated with the implementation of FBG based SHM systems in the aerospace FRP structures such as the difficulty of embedding FBG sensors during the manufacturing process and interrelation of distortion to FBG spectra due to internal damage, and other independent effects will be thoroughly studied. An innovative method to interpret FBG signals for identifying damage inside the structures will also be discussed.

Article PDF

Similar content being viewed by others

Avoid common mistakes on your manuscript.

References

F. K. Chang and K. Y. Chang, “A progressive damage model for laminated composites containing stress-concentrations,” Journal of Composite Materials, vol. 21, no. 9, pp. 834–855, 1987.

M. T. Kortschot and P. W. R. Beaumont, “Damage mechanics of composite materials: I-measurements of damage and strength,” Composites Science and Technology, vol. 39, no. 4, pp. 289–301, 1990.

S. Kamiya and H. Sekine, “Prediction of the fracture strength of notched continuous fiber-reinforced laminates by interlaminar crack extension analysis,” Composites Science and Technology, vol. 56, no. 1, pp. 11–21, 1996.

G. Zhou and L. M Sim, “Damage detection and assessment in fiber-reinforced composite structures with embedded fiber optic sensors-review,” Smart Materials and Structures, vol. 11, no. 6, pp. 925–939, 2002.

F. K. Chang, Structural Health Monitoring. Lancaster: DESTechnol Publications, 2003.

M. S. Reveley, T. Kurtoglu, K. M. Leone, J. L. Briggs, and C. A. Withrow, “Assessment of the state of the art of integrated vehicle health management technologies as applicable to damage conditions,” vol. NASA/TM-2010-216911, 2010.

K. O. Hill and G. Meltz, “Fiber Bragg grating technology fundamentals and overview,” Journal of Lightwave Technology, vol. 15, no. 8, pp. 1263–1276, 1997.

A. D. Kersey, M. A. Davis, H. J. Patrick, M. LeBlanc, K. P. Koo, C. G. Askins, M. A. Putnam, et al., “Fiber grating sensors,” Journal of Lightwave Technology, vol. 15, no. 8, pp. 1442–1463, 1997.

P. C. Hill and B. J. Eggleton, “Strain gradient chirp of fiber Bragg gratings,” Electronics Letters, vol. 30, no. 14, pp. 1172–1174, 1994.

M. LeBlanc, S. Y. Huang, M. M. Ohn, and R. M. Measures, “Tunable chirping of a fiber Bragg grating using a tapered cantilever bed,” Electronics Letters, vol. 30, no. 25, pp. 2163–2165, 1994.

Y. Okabe, S. Yashiro, T. Kosaka, and N. Takeda, “Detection of transverse cracks in CFRP composites using embedded fiber Bragg grating sensors,” Smart Materials and Structures, vol. 9, no. 6, pp. 832–838, 2000.

S. Takeda, Y. Okabe, and N. Takeda, “Delamination detection in CFRP laminates with embedded small-diameter fiber Bragg grating sensors,” Composites Part A: Applied Science and Manufacturing, vol. 33, no. 7, pp. 971–980, 2002.

Y. Wang, H. Bartelt, W. Ecke, R. Willsch, J. Kobelke, M. Kautz, et al., “Fiber Bragg gratings in small-core Ge-doped photonic crystal fibers,” in Proc. of Asia Pacific Optical Fiber Sensors Conference, Chengdu, China, Nov. 7–9, 2008.

L. I. Che-Hsien, K. Nishiguti, and M. Miyatake, “PPP-BOTDA method to achieve 2 cm spatial resolution in Brillouin distributed measuring technique,” in Proc. OFT2008-13, May 15–16, pp. 1–6, 2008.

R. Kashyap, Fiber Bragg gratings. San Diego: Academic Press, 1999.

A. D. Kersey, M. A. Davis, T. A. Berkoff, D. G. Bellemore, K. P. Koo, and R. TJones, “Progress towards the development of practical fiber Bragg grating instrumentation systems,” in Proc. SPIE, vol. 2839, pp. 40–63, 1996.

J. A. Guemes and J. M. Menéndez, “Response of Bragg grating fiber-optic sensors when embedded in composite laminates,” Composite Science and Technology, vol. 62, no. 2, pp. 959–966, 2002.

E. N. Barton, S. L. Ogin, A. M. Thorne, G. T. Reed, and B. H. Le Page, “Interaction between optical fiber sensors and matrix cracks in cross-ply GRP laminates-part 1: passive optical fibers,” Composite Science and Technology, vol. 61, no. 13, pp. 1863–1869, 2001.

Y. Okabe, R. Tsuji, and N. Takeda, “Application of chirped fiber Bragg grating sensor for identification of crack location in composites,” Composites Part A: Applied Science and Manufacturing, vol. 35, no. 1, pp. 59–65, 2004.

S. Yashiro, N. Takeda, T. Okabe, and H. Sekine, “A new approach to predicting multiple damage states in composite laminates with embedded FBG sensors,” Composites Science and Technology, vol. 65, no. 3–4, pp. 659–667, 2005.

J. A. Eparrachchi, J. Canning, and M. Stevenson, “The response of embedded NIR (830 nm) fiber Bragg grating (FBG) sensors in glass fiber composites under fatigue loading,” Journal of Composite Structures, vol. 44, no. 7, pp. 809–819, 2009.

K. Peters, M. Studer, J. Botsis, A. Iocco, H. Limberger, and R. Salathé, “Embedded optical fiber Bragg grating sensor in a nonuniform strain field: measurements and simulations,” Experimental Mechanics, vol. 41, no. 1, pp. 19–28, 2001.

M. Wu and W. P. Winfree, “Fiber optic thermal detection of composite delaminations,” in Proc. SPIE, vol. 8013, pp. 801314, 2011.

S. Takeda, Y. Okabe, and N. Takeda, “Monitoring of delamination growth in CFRP laminates using chirped FBG sensors,” Journal of Intelligent Material Systems and Structures, vol. 19, no. 4, pp. 437–444, 2008.

I. Yamauchi, S. Minakuchi, N. Takeda, and Y. Hidose, “Detection of arrested crack in foam core sandwich structures using embedded FBG sensors,” Kanagawa: DEStech Publications Inc., 2008.

S. D. Dyer, P. Williams, R. J. Espejo, J. D. Kofler, and M. Etzel, “Fundamental limits in fiber Bragg grating peak wavelength measurements,” in Proc. SPIE, vol. 5855, pp. 88–93, 2005.

G. C. Kahandawa, J. A. Epaarachchi, H. Wang, and J. Canning, “Effects of the self-distortions of embedded FBG sensors on spectral response due to torsional and combined loads,” in Proc. of APWSHM3, Tokyo, Japan, Nov. 30–Dec. 2, 2010.

G. C. Kahandawa, J. A. Epaarachchi, H. Wang, D. Followell, P. Birt, J. Canning, and M. Stevenson, “An investigation of spectral response of embedded fiber Bragg grating (FBG) sensors in a hollow composite cylindrical beam under pure torsion and combined loading,” in Proc. of ACAM 6, Perth, Australia, Dec. 13, 2010.

G. C. Kahandawa, J. A. Epaarachchi, and H. Wang, “Identification of distortions to FBG spectrum using FBG fixed filters,” in Proc. of ICCM18, Jeju, Korea, Aug. 21–26, 2011.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is published with open access at Springerlink.com

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Kahandawa, G.C., Epaarachchi, J., Wang, H. et al. Use of FBG Sensors for SHM in Aerospace Structures. Photonic Sens 2, 203–214 (2012). https://doi.org/10.1007/s13320-012-0065-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13320-012-0065-4