Abstract

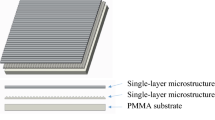

A new polymer masking system with photo-degradable material applicable to high-speed roll-to-roll vacuum deposition processing was studied. Specifically, a process using intense pulsed light to quickly and cleanly remove polymer masks was developed. Poly(methyl methacrylate) (PMMA) and TiO2 were blended together with the positive photoresist to prepare a photo-degradable polymer masking. Infrared spectroscopy confirmed that the positive photoresist moiety, diazonaphtoquinone, was photo-decomposed by white intense pulsed light. The process time required to remove the polymer mask was short enough that this method could be used even in high-speed roll-to-roll processes. It was confirmed that the polymer mask film could be easily removed even at a high process speed by using pressurized gas and adhesive roller tape. The transparent electrode was patterned using a polymer mask and an etching paste, and full solution processed inverted type OPV devices were fabricated. The fabricated OPV by direct etching showed a 94% efficiency compared with that of the reference device.

Similar content being viewed by others

References

K. Ali, K.-H. Choi, J. Jo, and Y. W. Lee, Mater. Lett., 136, 90 (2014).

K. Ali, K.-H. Choi, Langmuir, 30, 14195 (2014).

K. Ali, K.-H. Choi, and N. M. Muhammad, Chem. Vapor Depos., 20, 380 (2014).

T. Yamada, M. Ishihara, J. Kim, M. Hasegawa, and S. Iijima, Carbon, 50, 2615 (2012).

E. S. Polsen, D. Q. McNerny, B. Viswanath, S. W. Pattinson, and A. J. Hart, Sci. Rep., 5, 10257 (2015).

V. Miikkulainen, M. Leskelä, M. Ritala, and R. L. Puurunen, J. Appl. Phys., 113, 021301 (2013).

E. Ahvenniemi, A. R. Akbashev, S. Ali, M. Bechelany, M. Berdova, S. Boyadjiev, D. C. Cameron, R. Chen, and M. Chubarov, J. Vac. Sci. Technol. A, 35, 010801 (2016).

A. A. Malygin, V. E. Drozd, A. A. Malkov, and V. M. Smirnov, Chem. Vapor Deposition, 21, 216 (2015).

L. Guo, I. Lee, and F. Zaera, ACS Appl. Mater. Interfaces, 8, 19836 (2016).

A. Sinha, D. W. Hess, and C. L. Henderson, J. Electrochem. Soc., 153, G465 (2006).

B. Nketia-Yawson and Y.-Y. Noh, Macromol. Res., 25 489 (2017).

S. Park, S.J. Lim, J. Kim, and J.-W. Yu, Macromol. Res., 25 1022 (2017).

G. Grau, J. Cen, H. Kang, R. Kitsomboonloha, W. J. Scheideler, and V. Subramanian, Flex. Print. Electron., 1, 023002 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Acknowledgments: This work was supported by the Industrial Technology Innovation Program (Grant No. 10063277, Development of pattern deposition system based on roll to roll processing under low temperature and atmospheric pressure condition for smart thin film device fabrication) and was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIP) (Grant No. 2016R1A2B4012589).

Rights and permissions

About this article

Cite this article

Song, JH., Yim, S.J., Lim, S.J. et al. Polymer Masking Method for a High Speed Roll-to-Roll Process. Macromol. Res. 26, 838–843 (2018). https://doi.org/10.1007/s13233-018-6117-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13233-018-6117-x