Abstract

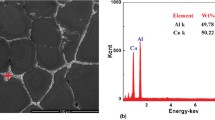

An effective alloying system for providing improved mechanical and technological properties of model cast Al–Cu alloys (Al-4.6%Cu-0.4%Mn-0.2%Ti), using magnetohydrodynamic (MHD) melt mixing, has been chosen in this research. It was shown that MHD treatment provides a non-dendritic (globular) ingot structure and can be applied to ensure thixotropy in the mass production of high-precision cast parts. Small additives of alloying elements that modify both grain structure (Mn, Zr) and reinforcing phases (Sn, In, Sc) were used. It is shown that the most effective alloying elements which improved the strength characteristics of the alloy are Sn and In. The introduction of 0.1–0.2% Sn or In followed by heat treatment led to a 50% increase in its yield strength, a 15% increase in the tensile strength. Sn and In modified the decomposition kinetics, providing a high density of precipitate and slow coalescence of nano-sized particles of the strengthening θ′-phase, which resulted in higher strength characteristics of the alloy.

Similar content being viewed by others

Abbreviations

- MHD:

-

Magnetohydrodynamic treatment

- DSC:

-

Differential scanning calorimetry

- TEM:

-

Transmission electron microscopy

- 3DAP:

-

Atom probe tomography

References

Banerjee S, Robi PS, Srinivasan A, Lakavath PK (2010) Effect of trace additions of Sn on microstructure and mechanical properties of Al–Cu–Mg alloys. Mater Des 31:4007–4015

Bourgeois L, Dwyer C, Weyland M, Nie J-F (2012) The magic thicknesses of θ′ precipitates in Sn-microalloyed Al–Cu. Acta Mater 609(2):633–644

Dubodelov V, Fikssen V, Slazhniev M, Goryuk M, Skorobagatko Iu, Seredenko E, Yashchenko O (2015) Modernization of casting magnetodynamic equipment. In: 8th international conference on electromagnetic processing of materials, Cannes, France. https://hal.archives-ouvertes.fr/hal-01336201

Nie JF, Muddle BC (2008) Strengthening of an Al–Cu–Sn alloy by deformation-resistant precipitate plates. Acta Mater 56(14):3490–3501

Polishchuk V, Horn R, Tsin M, Dubodelov V, Pogorsky V, Trefniak V (1989) Magnetodynamic pumps for liquid metals. Naukova dumka, Kyiv

Polmear IJ (2006) Light alloys. From traditional alloys to nanocrystals. Linacre House, Oxford

Ringer SP, Hono K, Sakurai T (1995) Nucleation and growth of θ′ precipitation in Sn-modified Al–Cu alloys: APFIM/TEM observations. Appl Surf Sci 87–88(2):223–227

Sankaran R, Laird C (1974) Effect of trace additions Cd, In and Sn on the interfacial structure and kinetics of growth of θ′ plates in Al–Cu alloy. Mater Sci Eng 14(3):271–279

Silcock JM, Flower HM (2002) Comments on a comparison of early and recent work on the effect of trace additions of Cd, In, or Sn on nucleation and growth of θ′ in Al–Cu alloys. Scripta Mater 46(5):389–394

Silcock JM, Heal TJ, Hardy HK (1954) Structural ageing characteristics of Aluminum–Copper alloys. J Inst Met 82:239–248

Stroganov GB (1985) Vysokoprochnyye liteynyye alyuminiyevyye splavy. Metallurgiya, Moskva

Totten G E, Tiryakioglu M, Kessler O (2018) Encyclopedia of Aluminum and its alloys, two-volume set (Print) CRC Press Taylor and Francis Group. https://doi.org/10.1201/9781351045636

Acknowledgements

This work was carried out within the frame of budget project 055/16 of the G.V. Kurdyumov IMP of the N.A.S. of Ukraine.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Berezina, A.L., Monastyrska, T.O., Molebny, O.A. et al. Effect of microalloying with transition and post-transition metals on the aging of precipitation-hardened Al–Cu alloys. Appl Nanosci 10, 4773–4780 (2020). https://doi.org/10.1007/s13204-020-01322-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01322-0