Abstract

Due to soaring demand for universal energy, industry forced to look forward in either expand the limit of conventional energy resources or to look at other possibilities such as renewable energy resources and unconventional hydrocarbon resources. The challenges might be figured out by revolutionary technological developments in the energy sector by science and technology. The industry needs splendid technological breakthroughs in the energy sector to push the final frontier of conventional energy resources. Owing to its superior particle size and properties, nanotechnology can likely of moving far that current energy supply by introducing new technologies. The exact exploitation and manipulation of matter at measurements of (1–100) nanometres have revolutionized many sectors, including the petroleum sector. The upgrade in nanoscale organized materials represents one of the fascinating, inventive viewpoints bringing innovative advances in numerous industries. The charge of oil extraction is under heavyweight, and it becomes increasingly difficult to legitimize it when the gross price of oil is powerless and depressing. There is a universal belief that nanotechnologies can be to produce new, more valuable nanomaterials to oppose these technological limitations. Many research endeavours are being coordinated towards the opening of immense and diverse advantages of nanotechnology in the oil and gas industry. The research experts have experienced the utilization of different nanoparticle types and sizes. Nanoparticles show exceptional properties because of their large surface area and highly activated particle surface. The nanotechnology can be performed at a different scale in petroleum engineering from exploration, drilling, cementing, reservoir, completion, production, and processing and refinery in each stage. This paper intends to give a concise thought of the significant uses of nanoparticles, their potential advantages, associated economic and technical challenges, and solutions.

Similar content being viewed by others

Introduction

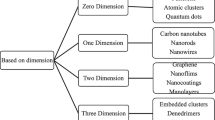

The control, coordination and integration of atoms and molecules at the nanoscale lead to emerging technological materials, structures, tools, devices, circuits, sensors and systems employing nanotechnology (Darjani et al. 2017; Mozaffari et al. 2016; 2018a; Li et al. 2019). Physically nano-sized particles have dimensions of one-billionth of a metre. Even dimensions of water molecules are roughly one-tenth of nanometres (Mozaffari et al. 2018b, 2019). The nanotechnology can construct and manipulate material at the molecular level that makes it likely to form something which has superior properties such as both being lightweight and high strength, and some capabilities like optical, mechanical, electrical and heat conductivity. The thermo-physical properties change with changes in shape, size, base fluid and volume proportion of fluid. Some of the researchers carried out theoretical and experimental studies on a nanofluid containing different shapes of nanoparticle (Hamilton and Crosser 1962; Timofeeva et al. 2009; Aaiza et al. 2015; Ellahi et al. 2016; Khan 2017). The rise of nanotechnology as a new power to rule in a multidisciplinary research study has prompted the advancement of nanomaterials and nanofluids, where the oil and gas industry can accept the modern advanced nanotechnology to tackle down to issue experienced in oilfield, particularly in enhanced oil recovery efficiency (Liu et al. 2017; Patel et al. 2020a, b; Pandya et al. 2019; Shah and Shah 2020; Shah et al. 2020). Owing to its superior nanometre scale ranging from 0.1 to 100 nm and unique properties, nanotechnology poised the significant influence on all sectors (Mokhatab et al. 2006; Muraza and Galadima 2015; Khalil et al. 2015, Wei et al. 2007, Chen et al. 2009). Nanoparticles, for their unique physicochemical characteristics, have brought attention in many industries, including the petroleum industry. Already, nanoscience is used or explored in critical areas related to remote sites including arctic and harsh deep sea condition and also unconventional reservoirs in every significant field of these industries, including exploration, drilling, monitoring, generation and processing and distribution. Notable of these are in the production sector. Here, the main objective of using nanometric particles is to change the reserve conditions needed to improve production economically. Nanomaterials can also solve problems with oil drilling by changing the quality of cake and reducing the sticking problems of tubes. Damage problems near the reservoir depend on the quality of the slime cake, which can be effectively modified using nanomaterials (Khan 2017; Thakkar et al. 2019).

Exploration and reservoir characterization

Hydrocarbon exploration is significant but very costly and risky assessments in the petroleum area (Patel et al. 2020a, b). Hydrocarbons are being investigated to determine the accumulation of hydrocarbons below the earth’s surface. However, it often encounters many challenges, such as geometric uncertainty and unexpected hazards that can affect the overall cost. Current probing technologies are not yet capable of exaggerating the high-resolution backup display and are unable to delve into the water to obtain adequate information about plumbers. Backup helps to estimate the reserve, characterize the tanks and monitor its performance. Moreover, many sensitive techniques, such as conventional electro-profiling, often cannot exaggerate reliable information under specific backup conditions. Despite advanced research techniques such as 3D and 4D seismic graph studies, the oil and gas sector still need an advance electrical method, sensitive electromagnetic imaging methods, sophisticated modelling and simulation techniques to improve deep-water understanding (Kong and Ohadi 2010).

Implementation of nanotechnology can enable predicting the accumulation of hydrocarbon and characterization of the reservoir. The size-dependent optical, chemical, electrical and magnetic characteristics of the nanoparticle can be used as nanosensor as it would be easily percolating through geological structure and give the information of the reservoir. A new sensing technique can also enable obtaining data of deeper reservoir region and complex interaction of geological formation with the immiscible fluid.

Magnetic nanomaterial can be potentially useful as a contrasting agent to control and evaluate the formation behaviour. The fundamental concept is that magnetic nanomaterial generates a magnetic field, which in turn decreases the speed of the electromagnetic wave, and 3D motion graph is obtained by determining the temporal fluctuations. The motion of magnetic nanoparticles/nanomaterial could be known preciously using electromagnetic waves which are transmitted by it and recorded on the receiver. From this method, the plot of the flow of reservoir fluid can be drawn assuming the laminar movement along with nanomaterials. In a recent study, Rahmani and co-workers carried out and experimented on ferrofluid to monitor the EM conductivity and magnetic tracing of its slug by the use of superparamagnetic iron oxide nanoparticle (SPION). It observed that ferrofluid alter the magnetic permeability of rock in a specific region at a shallow frequency which provides a high-resolution image of the flood (Rahmani et al. 2015).

In another study, Chi et al. (2016) used SPION as a contrasting agent and injected into rock and characterize their effect on Nuclear Magnetic Resonance (NMR). The combination of SPION with NMR relaxometry enables enhancing the characterization process to find the pore size distribution, its connectivity and fractures in rocks.

The previously fabricated all the experiments show that the nanosensor and nanorobot would be able to sense the reservoir condition (high salinity, pH, Ca2+, high temperature, fluid behaviour and all the information about useful reservoir mapping).

To detect hydrocarbons in oilfield rocks, Berlin et al. (2011) and Hwang et al. (2012) used sulphated and unsulphated polyvinyl alcohol-functionalized oxidized carbon black (PVA-OCB) nanoparticles. In this approach, nanoreporter (sulphated PVA-OCB) helps to transport noncovalently attached probe molecules through the heterogeneous formation and selectively anticipating when the rock contains oil. It gives quantitative information on oil content based on probe molecule remaining in the nanoreporter. Additionally, the same concept is applied by Hwang et al. (2014) for the detection of H2S. In this approach, polyvinyl alcohol-activated carbon black with H2S sensor is injected in oil and water containing porous medium and based on the enhancement of fluorescent level in production, well H2s content can be determined.

Another new implemented application of nanomaterial-based sensing device for monitoring substance such as toxic, hazardous and flammable gas is essential for crew member’s health and safety in petroleum extraction and storage operation. In a recent study, Piantanida and co-workers have demonstrated a small, economically feasible, low magnitude power, highly sensitive and correctly sensing for the hydrogen sulphide (H2S) based on WO3 nanoparticles. In another study, Turkenburg et al. (2012) have demonstrated water-dispersed nanosensor for the waterflooding process which is based on a cocktail containing InP/ZnS quantum dots (QDs) and atomic silver (Ag) cluster with a bright luminescence to improve sensor functionalities (Fig. 1).

Drilling

Drilling fluids

The drilling operation is the most critical, high-risk operations to access the reservoir in the oil and gas sector. The perfect formulation and expertly designed drilling fluids are a road map to exceed the target depth of the hydrocarbon reservoir. There are water-based fluid, oil or synthetic-based fluids and pneumatic-based fluids generally used in the oil and gas industry in different conditions (Sadeghalvaad et al. 2015). The different types of nanoparticles (NPs) of size (1–100 nm) are in colloidal suspension considered to be nano-based fluids. In the account of physico-chemical properties of NPs, higher surface area and higher thermal conductivity, NPs in addition of additive could be able to improve the characteristics and performance of drilling fluid in terms of thermal stability, wellbore stability, salinity control, the formation of filter cake, rheological stability and mud filtration properties.

The rheology of drilling fluid is an important term which affects the drilling performance. The prime objective of a drilling fluid should be less resistant at higher shear rate, and that can be obtained by shear thinning characteristics of a drilling fluid. NPs can improve the rheological properties of drilling fluid by various mechanisms, and that depends on type and characteristics of NPs. Table 1 gives the summaries of various NPs on modification of rheological properties of drilling fluid.

For the better development of drilling fluid, William and co-workers identified that the nanofluid CuO and ZnO with xanthan gum aqueous solution which are termed as nanofluid-enhanced water-based drilling muds (NWBM) improve the rheological, thermal and electrical properties. They also reported that NWBM based on CuO nanofluid shows enhanced thermal properties and offers more resistant to HPHT condition in contrast to ZnO-based NWBM (William et al. 2014). Again, Ponmani and co-worker investigated the alteration of thermal, electrical and fluid loss properties of NWBM. They studied an effect of nanofluid CuO and ZnO with the base fluids such as polyvinylpyrrolidone (PVP), polyethylene glycol (PEG) and xanthan gum for the application of drilling fluid. They viewed that fluid loss decreases with the addition of nanofluids in WBM and also increases the thermal and electrical properties of nano-based drilling mud (Ponmani et al. 2016). Additionally, Liu et al. (2017) investigated new synthesized cellulose nanofibres (CNFs) which are renewable, non-toxic and relatively less expensive to synthetic polymers and its impact on water-based drilling fluid for rheology and filtration control. They observe that CNFs provide ideal performance for rheology and mud filtration control which transcend thermal stability of xanthan gum.

For filtration loss of drilling fluid into the formation, Shakib et al. (2016) studied the effect of different nanomaterials like nano-titanium, nano-copper oxide, nano-alumina and nano-clay on water-based drilling fluid. The experimental studies show that all these materials have superior properties in comparison with conventional additive and mud cake formed by the nano-clay has significantly lower permeability which reduces the filtrations.

Recently, Ahmad and co-workers studied the effect of novel water-soluble polymers and NPs on bentonite drilling fluid. They observed that NPs improve the filtration properties by decreasing the fluid loss in the formation and highly permeable zone by making thin filter cake for the smooth drilling operation. In contrast, the polymers enhance the rheological characteristics and dispersion of bentonite (Ahmad et al. 2017).

For high-pressure, high-temperature (HPHT) drilling, Fe2O3 and Fe3O4 are found to be an excellent and effective additive in drilling fluid. An optimum concentration of NPs bring significant benefits to obtain better cake quality. The Fe2O3 and Fe3O4 nanoparticles are enabled to improve the filter cake and filtration characteristic of bentonite-based drilling fluids at downhole condition up to 500 psi and 350 °F. Additionally, NPs can also allow developing the filtration characteristics in the static and dynamic state (Vryzas et al. 2016; Mahmoud et al. 2017).

Drilling bits

A drilling bit is a tool for cutting and grinding of formation which is placed at the distal end of the drill string. Polycrystalline diamond compact (PDC) bits are commonly used in drilling technology. Nanotechnology has the potential to design drill bits more appropriate and affordable for drilling jobs. Due to having a unique property of nanomaterials such as mechanical, electrical and thermal properties, they can be able to improve the performance of drilling bits. Chakraborty and co-workers investigated the working rule of nanodiamond, return on PDC cutters and property alteration in contrast to base PDC matrix. They witnessed that nanodiamond PDC technology can enable one to drill in harsher condition and demanding reservoir condition (Chakraborty et al. 2012).

Furthermore, Sengupta and Kumar (2013) studied the effect of Al2O3–TiO2 coating on drilling bit via a plasma coating method to improve the bit life and mitigate bit string trips. They observed that bond strength and toughness are doubling compared to conventional coating.

Cementation

The principal challenges in ensuring the well integrity in oil and gas exploration are the stability and integrity of the cement sheath around the carbon steel casing. Typically, there are several cementing problems during the drilling and production operation, such as casing centralization, inadequate cement formation, excessive wellbore damage during drilling, shrinkage of cement, incomplete cement placement, filtration of cement slurry to nearby formation and well integrity, micro-annuli in cement, cement failure due to mechanical or thermal stress, corrosion of casing and many more. To overcome this issue, selecting cementing material and its operation play a significant role in oil and gas exploration and production. Recently, developed smart cement materials in nanoscale act as additives with superior characteristics to solve or improve numerous practical issues by enhancing mechanical strength, heat and electrical conductivity and reducing permeability and porosity.

There are many types of metal oxide NPs with different additives, such as nano-silica (Lin et al. 2008; Jo et al. 2007; Qing et al. 2007; Jalal et al. 2015; Nili and Ehsani 2015), TiO2 (Nazari and Riahi 2010a, b, 2011a, b, c, d; Zhang et al. 2015), Al2O3 (Nazari and Riahi 2011a, b, c, d, 2012), ZrO3 (Nazari and Riahi 2010a, b, 2011a, b, c, d), Fe2O3 (Li et al. 2004; Khoshakhlagh et al. 2012), Fe3O4 (Sikora et al. 2016; Horszczaruk et al. 2017), CuO (Riahi and Nazari 2011; Khotbehsara et al. 2015), ZnO2 (Nazari and Azimzadegan 2012) and other types of magnetic nanoparticle (Blyszko et al. 2008), which improve the properties of concrete and cements, such as strength, resistance to water or air penetration, and provide self-compacting and many more.

Recently, it is noted that multi-walled carbon nanotubes (MWCNTs) can improve the properties of cement, such as impact toughness and durability, dry shrinkage capacity and permeability resistance (Yu and He 2015; Wang 2015). Additionally, the ultra-low proportion of carbon nanotubes (CNTs) and carbon nanofibres (CNFs) can able to modify the electrochemical properties of cement paste (Wong et al. 2015). Furthermore, Konsta-Gdoutos and co-workers investigated the impact of the carbon nanotubes (CNTs) and nanofibres (CNFs), and their dispersion on the corrosion performance, strength, electrical resistivity and mechanical properties of nano-modified Portland cement mortars (Konsta-Gdoutos et al. 2017). They conclude that CNTs and CNFs reduced corrosion rate by postponing onset corrosion activity, and so, ultimately, the increase in corrosion resistance is noticed.

Reservoir characterization and management

Nanotechnology enhances production by improving the effectiveness of various parameters at the nanoscale. Reservoir characterization has more importance in the petroleum industry. The optimization of the lifetime of a reservoir gives better performance for a long time. Many factors affected the reservoir characterization and management. In this unit, it involves the different NPs that are suitable to get more production.

Enhanced oil recovery

The nanotechnology enhanced oil recovery based on the incorporation of NPs and nanofluids to improve the conventional EOR processes. It covers the application of NPs in both chemical enhanced oil recovery (CEOR) and thermal enhanced oil recovery (TEOR).

Chemical enhanced oil recovery (CEOR)

Chemical methods for EOR can modify some important parameters which have high importance for the production of hydrocarbons (HCs), such as mobility ratio (M), interfacial tension (IFT), wettability and the effect of chemical solutions on a reservoir rock surface. CEOR can alter this parameter in favour of improving oil recovery by changing the mechanism of HCs such as IFT reduction, viscosity and wettability alteration and trapped out the HCs from pore spaces (Ali et al. 2018). NPs can change the oil recovery mechanisms to trap out the oil from pore spaces of the reservoir.

Interfacial tension (IFT) reduction

NPs can alter the rheological properties of the reservoir fluid by improving the efficiency of the surfactant solution for oil recovery. NPs focus on reducing the interfacial tension between the oil and rock interface or between the surfactant and oil interface. The NPs reduce the adsorption on a rock surface by enhancing disjoining pressure by forming wedge film on structure at the interface of oil and rock surface (Wasan and Nikolov 2003; Wasan et al. 2011) (Fig. 2).

Surfactant flooding reduces the interfacial tension by injecting surfactants such as indium oxide (IO) NPs coated with Si substrates (Munshi et al. 2008). Munshi et al. (2008) studied the variation in the value of the static contact angle, which was measured on indium oxide (IO) NPs that have different nano-sizes. The study showed that the NPs size has a direct impact on contact angle measurements.

Suleimanov et al. (2011) studied the nanofluids, which are a mixture of NPs and fluids for improvement in properties of liquid with low volume proportion. The study showed that a solution of anionic surface active with light non-ferrous metal NPs was able to reduce surface tension up to 70–90% with a comparison of any surface-active agent aqueous solution. It is observed that in the presence of NPs the sulphanole adsorption process is more stable and the value of surfactant adsorption exceeds by 14.5–18.5 times.

Ahmadi et al. (2017) studied the integration effect of hydrophilic nano-silica in addition to surfactant separated from leaves of Ziziphus spina-christi. The result showed that with a rising proportion of hydrophilic nano-silica, ultimately recovery rises from 81.08 to 83.45% originally oil-in-place (OOIP). The oil recovery increased due to a reduction in the mobility ratio between oil and injection fluid with increasing viscosity of the injecting fluid.

Pouriya Esmaeilzadeh et al. (2014) demonstrate the mixture containing both surfactants and ZrO2 to understand the air–water and oil–water tension of the system. The study also involved the ionic and nonionic surfactant in decreasing air–water surface tension. Some anionic surfactants are sodium dodecyl sulphate (SDS), cationic surfactant dodecyl trimethyl ammonium bromide (C12TAB) and nonionic surfactant lauryl alcohol 7-mole ethoxylate (LA7).

Joonaki and Ghanaatian (2014) introduce the NPs such as aluminium oxide, silicon oxide and iron oxide treated by saline. The study showed that with the addition of silicon, it changes the rock wettability rather than a decline of interfacial tension between oil and water. The survey of Moghadam and Azizian (2014) involved the measurement of interfacial tension between sodium dodecyl sulphate as an anionic surfactant and ZnO NPs. They witnessed that the ZnO NPs make the SDS molecules more capable of reducing the interfacial tension.

Javad Saien et al. (2013) studied the impact of hydrophobic NPs and hydrophilic solutions on interfacial tension of oil and water. The alumina as a hydrophilic and hexadecanoic acid act as a hydrophilic solution, and these NPs are dissolved in aqueous or organic phases to design a stable nanofluid. Still, with a change in temperature, the reduction in interfacial tension occurs (Table 2).

Wettability alteration

Ali Esfandyari Bayat et al. (2014) studied the aluminium oxide (Al2O3), titanium dioxide (TiO2) and silicon dioxide (SiO2) to enhance the oil recovery from an intermediate-wet limestone sample for various temperatures. The adsorption of Al2O3 was the highest, and for SiO2 and TiO2 adsorption was the highest on the limestone surface. By adsorption of NPs, the wettability of the limestone was changed from oil-wet to water-wet. The experiments showed that Al2O3 and TiO2 have a higher effect on the wettability alteration than the SiO2.

Moghaddam et al. investigate in 2015 the impact of nanomaterials on the susceptibility of moisture to carbonate rocks. Nanocomposites are consisting of titanium dioxide (TiO2), silicon dioxide (SiO2), magnesium oxide (MgO), aluminium oxide (Al2O3), cerium oxide (CeO2), zirconium dioxide (ZrO2) and carbon nanotubes (CNT). The study indicated that the disjoining pressure gradient is the primary factor for changing wettability. From theoretical experiments and calculations, it proved that the separation pressure of the NP layer nearby contact point was able to remove oil from the surfaces (Fig. 3).

FESM image from limestone grains after the flooding of TiO2 and SiO2 (Moghaddam et al. 2015)

Hendraningrat and Torsæter (2014) studied the hydrophilic metal oxide NPs for EOR in various reservoir rock samples. This study shows the better result for oil recovery than the conventionally used silica-based nanofluids. Also, the quartz plates changed from oil-wet to water-wet system by metal oxide nanoparticles, and by adding PVP of 1 wt.%, the durability of metal oxide nanoparticle improves significantly.

Ju and Fan (2009) investigated about the polysilicon nanoparticles (PN) for EOR process. The result shows alteration of wettability of sandstone by lipophobic and hydrophilic polysilicon nanoparticles (LHPNs), which proves that injecting polysilicon nanoparticles is beneficial for the water injection process (Table 3).

Thermal enhanced oil recovery (TEOR)

Thermal enhanced oil recovery is an approach to improve the residual oil from the reservoir by heating the reservoir. Applied heat reduces the viscosity of oil or vaporizes the part of the oil, and so mobility ratio is decreased. Also, by heating, the permeability of the reservoir is increased, and the surface tension is reduced. TEOR includes various methods such as cyclic steam injection, combustion and steam flooding.

Hamedi Shokrlu and Babadagli (2010) studied the mechanisms to reduce the viscosity of heavy oil or bitumen by nano-sized metal particles for steam injection processes. The main advantage of the nano-size metal particle is that it can able to reduce the oil viscosity even at room temperature without steam stimulation. The study observed that catalysing the hydrogenation reactions of aqua-thermolysis process was the primary mechanism behind the function of nano-size metal particles. These NPs can improve the oil recovery with different methods such as steam stimulation, electrical or electromagnetic technique. NPs affect the properties of reservoir like dielectric properties, electrical conductivity and magnetic permittivity in favour of improving the displacement efficiency and sweep efficiency.

Hamedi Shokrlu and Babadagli (2014) reported the various types of metal suitable for conventional and unconventional heavy oil or bitumen recovery. The study involved the micron to nano-size particle of metal iron, nickel and copper. The study observed that the heat transfer magnitude altered by changing the size of NPs and reduction in viscosity affected by the oil composition. The selection of metal is critical, and the thermal conductivity of the metal should be high.

Davidson (2012) studied the superparamagnetic NPs for magnetic induction heating using the concept of Neel relaxation. The study involved the single-domain Fe3O4 NPs of approximately 10 nm size and noted that the rate of heat transfer is three times greater than the static fluid.

Nano-sensors for hydrocarbon detection in oilfield rocks

With increasing concern of hydrocarbon contamination and increasing need for low cost and in situ instrumentation, the hydrocarbon detectors provide a better detection. The function of the indicators depends on the characteristic of the compounds which are to be detected. Nowadays, optical fibres are generally used to identify hydrocarbon such as PetroSense hydrocarbon sensors.

NPs can detect the fluid and rock properties because NPs have a minimum retention time. Yu et al. (2010) studied the paramagnetic NPs to detect fluid saturation. The NPs identify the fluids by the application of a magnetic field and measuring the response of the NPs towards the magnetic field.

Berlin et al. (2011) demonstrate the basic design for a sequestering hydrophobic compound in an oxidized carbon core composed of NPs. By using the oxidized carbon black (OCB) as the core and polyvinyl alcohol (PVA) as the shell, effective release of 2,2’,5,5’-tetrachlorobiphenyl (PCB) occurs. By injecting the NPs bearing cargo into the subsurface, and then recovering and analysing for the presence of cargo, a release of cargo predicts the presence of oil. When NPs are used in such approaches, NPs can be called as nanoreporters (Fig. 4).

Schematic of oil detection by nanoreporters. a Polyvinyl alcohol (PVA)—organic carbon black (OCB) NPs are injected into the subsurface. b The nanoreporters sense the oil and release their hydrophobic cargo into the oil. c The nanoreporters are recovered and analyzed for the presence of the cargo’s absence in the PVA-OCB, which indicates the extent of subsurface oil

Oil microbe detection tool using nanoparticles

NPs have a stronger magnetic, electrical and specific optical properties compared to the bulk one. Thus, nanotechnology has a more significant application in oil microbe detection.

Ramanan Krishnamoorti, University of Houston 2006, observed the formation of imaging contrast agents by altering the magnetic, electrical and optical properties of NPs at lower volume fraction and showed that nanomaterials are suitable for the development of detection tool. Taking the advantage, the relation of the anisotropic nature of NPs and the relationship of percolation with orientation, nanomaterials have an ability for oil microbe detection. Such nanomaterials, with a combination of smart fluids, can be applied in sensitive sensors for prediction of temperature, downhole stress and pressure.

Jahagirdar studied the detection of downhole by resonance Raman spectra based on the identification of chemotaxonomic markers presence. The study also involved the nanoscale optical fibre and microbes for microbially enhanced oil recovery. The study concludes that the tool will help in the detection of hidden droplets of oil and the zones which cannot recognise easily.

Refining and processing

The commercial utilization of miniaturization of materials serves a lot in petrochemical industries for almost 100 years (El-Diasty and Ragab 2013). In the refining process, nano-catalyst is utilizable for upgrading low API crude to improve refining potential and efficiency (Fan et al. 2010; Almao 2012; Peng et al. 2017).

Crude with API gravity less than 20° can be upgraded to lighter crude using high temperature and long reaction duration along with severe environmental pollution. However, carbon NPs can enhance and improve this cracking process by completing the same reaction at relatively less temperature (about 150 °C) and shorter time (< 1 h) in a cheaper and more environmentally friendly way (Li et al. 2014).

The alternative way for thermal cracking of hydrocarbon is implemented by powder catalyst, which lowers the activation energy of the reaction, along with an increase in reaction sites by increasing the surface energy. Use of zeolite catalyst in face-centred cubic (FCC) structure has been a revolution in the petrochemical industry whose contributions are continuously felt hitherto; over seven million of chemicals and petroleum products are annually produced using this catalyst (Zhou 2007).

Nano-filters and nanomaterials can remove toxic materials from petroleum products such as sulphide by unsupported metal sulphide catalyst. Furthermore, to improve the efficiency of desulfurization, the particles size needs to be reduced, and this simplifies the application process (Li and Zhu 2012). Also, catalysts based on cobalt, nickel and molybdenum on various supports are beneficial for desulfurization (Sudhakar 1998; Mohajeri et al. 2010; Li and Zhu 2012; Etim et al. 2018). This catalyst can also be reusable because after three rounds of oxidative desulfurization it also exhibits an excellent catalytic activity which is quite valuable for industrial utilization (Rafiee and Rezaei 2016; Etim et al. 2018).

Future challenges

Nanotechnology can improve the outcomes of the various ongoing conventional methods in an efficiently and environmentally friendly manner. The following are the potential possibilities that nanotechnology can enhance the undergoing process (Jackson 2005; Mokhatab et al. 2006; Esmaeili 2009):

-

1.

It improves the accuracy of exploration data, which is useful to avoid the problem of drying wells and identify shallow risks.

-

2.

It enhances the mechanical durability of drilling tools, which in turn improves drilling performance and reliability in harsh HPHT conditions.

-

3.

It promotes greater accuracy in production data, which ensures proper diagnosis useful for management strategies.

-

4.

It is useful for building corrosion-resistant production and drilling tools.

-

5.

The manufacture of materials with many nanomaterials reduces machine weight and is necessary for offshore operations.

-

6.

It modifies the properties of the reservoir, which can convert a large amount of probable and possible reservoirs into the proved reservoir.

-

7.

Modified waste management strategy is a new advanced option and can also allow selective water filtration.

-

8.

It is useful in refining and petrochemical techniques.

Conclusion

Nowadays, the pioneering nanotechnology has been extensively implemented in various aspects of the oil and gas sector, and it may become one of the critical factors to rupture through the bottleneck of oil and gas development technologies. The unique sized nanomaterial has done revolutionary changes in each sector of hydrocarbon exploration, drilling production and development. In oil and gas exploration sector, the nanotechnology will be practically applied and developed mainly in the reservoir mapping, as it is helpful in reserve estimation, reservoir characterization and its performance monitoring. Nanoparticles improve the efficiency of downhole imagining tools by advancing the downhole electrical methods and increase the sensitivity of the electromagnetic imaging methods; this in turns useful for sophisticated modelling and better understanding of the reservoir. In the drilling section, the use of NWBM has been mentioned, and its different functions in enhancing the rheological properties compared to the conventional one. Nanoparticles can make the drilling operation runs smoother, effective and in cost constraint. The modification of the drilling equipment and various fluids are potential for making drilling operation run without the problems of high fluid loss in the formation, wellbore instability, friction, dragging in wellbore and pipe sticking. Cement properties are improved by utilization of nanoparticles, improving properties like toughness, durability and dry shrinkage. This solution is useful for overcoming the significant challenges that occur in the unconventional and deep-water reservoir. Nanoparticles with the surfactant effectiveness at the interfacial layers reduce IFT.

Additionally, in the form of catalysts and absorbents nanoparticles can able to improve or enhance heavy oil recovery. Various techniques developed by researchers could perform the synthesis of nanoparticles. The nanoparticle-based drilling fluid can alter the wettability to improve the hydrocarbon recovery. Furthermore, nanofluid injection into porous and permeable media can cause the change in viscosity by inhibiting the precipitation, agglomeration and deposition of asphaltenes molecules onto the rock surface, which leads to improving oil recovery factor. The newly invented synthesis method of nanomaterials, widespread application of conventional nanomaterials and unique properties of nano-sized particles will continuously emphasize the nanomaterials in the oil and gas industry.

Availability of data and material

All relevant data and material are presented in the main paper.

References

Aaiza G, Khan I, Shafie S (2015) Energy transfer in mixed convection MHD flow of nanofluid containing different shapes of nanoparticles in a channel filled with saturated porous medium. Nanoscale Res Lett 10(1):490

Abdo J, Haneef MD (2013) Clay nanoparticles modified drilling fluids for drilling of deep hydrocarbon wells. Appl Clay Sci 86:76–82

Abdo J, Zaier R, Hassan E, Al-Sharji H, Al-Shabibi A (2014) ZnO-clay nanocomposites for enhance drilling at HTHP conditions. Surf Interface Anal 46:970–974

Agarwal S, Tran P, Soong Y, Martello D, Gupta RK (2011) Flow behavior of nanoparticle stabilized drilling fluids and effect of high temperature aging. In: AADE National Technical Conference and Exhibition, Texas, USA

Ahmad HM, Kamal MS, Murtaza M, Al-Harthi MA (2017) Improving the drilling fluid properties using nanoparticles and water-soluble polymers. In: SPE Kingdom of Saudi Arabia annual technical symposium and exhibition. Society of Petroleum Engineers

Ahmadi MA, Shadizadeh SR (2017) Nano-surfactant flooding in carbonate reservoirs: a mechanistic study. Eur Phys J Plus 132:246. https://doi.org/10.1140/epjp/i2017-11488-6

Ali JA, Kolo K, Manshad AK, Mohammadi AH (2018) Recent advances in application of nanotechnology in chemical enhanced oil recovery: effects of nanoparticles on wettability alteration, interfacial tension reduction, and flooding. Egypt J Pet. https://doi.org/10.1016/j.ejpe.2018.09.006

Almao PP (2012) In situ upgrading of bitumen and heavy oils via nanocatalysis. Can J Chem Eng 90(2):320–329. https://doi.org/10.1002/cjce.21646

Anoop K, Sadr R, Al-Jubouri M, Amani M (2014) Rheology of mineral oil-SiO2 nanofluids at high pressure and high temperatures. Int J Therm Sci 77:108–115

Applications of Nanotechnology in Oil and Gas Industry (2016) Faseeh Ahmad Khan, Aarushi Ohri and Vikas Nain

Aurand KR, Dahle GS, Torsæter O (2014) Comparison of oil recovery for six nanofluids in Berea Sandstone Cores, SCA A064, 1–12

Barry MM, Jung Y, Lee J-K, Phuoc TX, Chyu MK (2015) Fluid filtration and rheological properties of nanoparticle additive and intercalated clay hybrid bentonite drilling fluids. J Pet Sci Eng 127:338–346

Berlin JM, Yu J, Lu W, Walsh EE, Zhang L, Zhang P et al (2011) Engineered nanoparticles for hydrocarbon detection in oil-field rocks. Energy Environ Sci 4:505–509

Blyszko J, Kiernozycki W, Guskos N, Zolnierkiewicz G, Typek J, Narkiewicz U et al (2008) Study of mechanical properties of concrete with low concentration of magnetic nanoparticles. J Non-Cryst Solids 354:4515–4518

Chakraborty S, Agrawal G, DiGiovanni A, Scott DE (2012) The trick is the surface-functionalized nanodiamond PDC technology. Paper SPE-157039eMS. In: Presented at SPE international oilfield nanotechnology conference and exhibition, Noordwijk, The Netherlands

Chen Y, Wang Y, Lu J, Wu C (2009) The viscosity reduction of nanokeggin-K3PMo12O4 in catalytic aquathermolysis of heavy oil. Fuel 88(8):1426–1434

Chi L, Cheng K, Heidari Z (2016) Improved assessment of interconnected porosity in multiple-porosity rocks by use of nanoparticle contrast agents and nuclear-magnetic-resonance relaxation measurements. SPE Reserv Eval Eng 19(01):095–107

Darjani S, Koplik J, Pauchard V (2017) Extracting the equation of state of lattice gases from random sequential adsorption simulations by means of the Gibbs adsorption isotherm. Phys Rev E. https://doi.org/10.1103/physreve.96.052803

Davidson AM (2012) Magnetic induction heating of superparamagnetic nanoparticles for applications in the energy industry. Thesis, University of Texas at Austin

El-Diasty AI, Ragab AMS (2013) Applications of nanotechnology in the oil & gas industry: latest trends worldwide & future challenges in Egypt. North Africa Tech Conf Exhib. https://doi.org/10.2118/164716-ms

Ellahi R, Hassan M, Zeeshan A, Khan AA (2016) The shape effects of nanoparticles suspended in HFE-7100 over wedge with entropy generation and mixed convection. Appl Nanosci 6(5):641–651

Emadi S, Shadizadeh SR, Manshad AK, Rahimi AM, Mohammadi AH (2017) Effect of nano silica particles on interfacial tension (IFT) and mobility control of natural surfactant (Cedr Extraction) solution in enhanced oil recovery process by nano-surfactant flooding. J Mol Liq 248:163–167

Esfandyari Bayat A, Junin R, Samsuri A, Piroozian A, Hokmabadi M (2014) Impact of metal oxide nanoparticles on enhanced oil recovery from limestone media at several temperatures. Energy Fuels 28(10):6255–6266. https://doi.org/10.1021/ef5013616

Esmaeili A (2009) Applications of nanotechnology in oil and gas industry. Presented at Petrotech 2009 Conference held in New Delhi, India

Esmaeilzadeh P, Hosseinpour N, Bahramian A, Fakhroueian Z, Arya S (2014) Effect of ZrO2 Nanoparticles on the interfacial behavior of surfactant solutions at air–water and n-heptane–water interfaces. Fluid Phase Equil. 361:289–295

Etim UJ, Bai P, Yan Z (2018) Nanotechnology applications in petroleum refining. In: Saleh T (ed) Nanotechnology in oil and gas industries. Topics in mining, metallurgy and materials engineering. Springer, Cham

Fan X-B, Tao Z-Y, Xiao C-X, Liu F, Kou Y (2010) Liquid-phase Fischer–Tropsch synthesis over Fe nanoparticles dispersed in polyethylene glycol (PEG). Green Chem 12(5):795. https://doi.org/10.1039/b926397g

Halali MA, Ghotbi C, Tahmasbi K, Ghazanfari MH (2016) The role of carbon nanotubes in improving thermal stability of polymeric fluids: experimental and modeling. Ind Eng Chem Res 55:7514–7534

Hamedi Shokrlu Y, Babadagli T (2010) Effects of nano-sized metals on viscosity reduction of heavy oil/bitumen during thermal applications. In: Canadian Unconventional Resources and International Petroleum Conference. https://doi.org/10.2118/137540-ms

Hamedi Shokrlu Y, Babadagli T (2014) Viscosity reduction of heavy oil/bitumen using micro- and nano-metal particles during aqueous and nonaqueous thermal applications. J Pet Sci Eng. 119:210–220. https://doi.org/10.1016/j.petrol.2014.05.012

Hamilton RL, Crosser OK (1962) Thermal conductivity of heterogeneous two-component systems. Ind Eng Chem Fundam 1(3):187–191

Horszczaruk E, Brzozowski P, Sikora P, Cendrowski K, Mijowska E (2017) The effect of nanomagnetite on the shielding properties of cementitious composites. Constr Mater Syst, p 55

Hwang CC, Wang L, Lu W, Ruan G, Kini GC, Xiang C et al (2012) Highly stable carbon nanoparticles designed for downhole hydrocarbon detection. Energy Environ Sci 5:8304–8309

Hwang CC, Ruan G, Wang L, Zheng H, Samuel ELG, Xiang C et al (2014) Carbon-based nanoreporters designed for subsurface hydrogen sulfide detection. ACS Appl Mater Interfaces 6:7652–7658

Jackson SA (2005) Innovation and human capital: energy security and the quiet crisis. American Petroleum Institute

Jalal M, Pouladkhan A, Harandi OF, Jafari D (2015) Comparative study on effects of Class F fly ash, nano silica and silica fume on properties of high performance self-compacting concrete. Constr Build Mater 94:90–104

Jo BW, Kim CH, Tae G, Park JB (2007) Characterization of cement mortar with nano-SiO2 particles. Constr Build Mater 21:1351–1355

Joonaki E, Ghanaatian S (2014) The application of nanofluids for enhanced oil recovery: effects on interfacial tension and coreflooding process. Pet Sci Technol 32:2599–2607

Ju B, Fan T (2009) Experimental study and mathematical model of nanoparticle transport in porous media. Powder Technol 192(2):195–202. https://doi.org/10.1016/j.powtec.2008.12.017

Karimi A, Fakhroueian Z, Bahramian A, Pour Khiabani N, Darabad JB, Azin R, Arya S (2012) Wettability alteration in carbonates using zirconium oxide nanofluids: EOR implications. Energy Fuels 26(2):1028–1036. https://doi.org/10.1021/ef201475u

Khalil M, Lee RL, Liu N (2015) Hematite nanoparticles in aquathermolysis: a desulphurization study of thiophene. Fuel 145:214–220

Khan I (2017) Shape effects of MoS2 nanoparticles on MHD slip flow of molybdenum disulphide nanofluid in a porous medium. J Mol Liq 1(233):442–451

Khoshakhlagh A, Nazari A, Khalaj G (2012) Effects of Fe2O3 nanoparticles on water permeability and strength assessments of high strength self-compacting concrete. J Mater Sci Technol 28:73–82

Khotbehsara MM, Mohseni E, Yazdi MA, Sarker P, Ranjbar MM (2015) Effect of nano-CuO and fly ash on the properties of self-compacting mortar. Constr Build Mater 94:758–766

Kong X, Ohadi M (2010) Applications of micro and nano technologies in the oil and gas industry-overview of the recent progress. In: Abu Dhabi international petroleum exhibition and conference. Society of Petroleum Engineers

Konsta-Gdoutos MS, Batis G, Danoglidis PA, Zacharopoulou AK, Zacharopoulou EK, Falara MG, Shah SP (2017) Effect of CNT and CNF loading and count on the corrosion resistance, conductivity and mechanical properties of nanomodified OPC mortars. Constr Build Mater 147:48–57

Krishnan S, Abyat, Z, Chok C (2016) Characterization of boron-based nanomaterial enhanced additive in water-based drilling fluids: a study on lubricity, drag, ROP and fluid loss improvement. In: SPE/iadc middle east drilling technology conference and exhibition. https://doi.org/10.2118/178240-ms

Krishnamoorti R (2006) Extracting the benefits of nanotechnology for the oil industry. J Pet Technol 58(11):24–26. https://doi.org/10.2118/1106-0024-jpt

Li YH, Zhu YQ (2012) Research progress of unsupported nano catalyst. Adv Mater Res 550–553:284–291. https://doi.org/10.4028/www.scientific.net/amr.550-553.284

Li H, Xiao H, Yuan J, Ou J (2004) Microstructure of cement mortar with nanoparticles. Compos B Eng 35:185–189

Li K, Hou B, Wang L, Cui Y (2014) Application of carbon nanocatalysts in upgrading heavy crude oil assisted with microwave heating. Nano Lett 14(6):3002–3008. https://doi.org/10.1021/nl500484d

Li W, Ivanov S, Mozaffari S, Shanaiah N, Karim AM (2019) Palladium acetate trimer: understanding its ligand-induced dissociation thermochemistry using isothermal titration calorimetry, X-ray absorption fine structure, and 31p nuclear magnetic resonance. Organometallics 38:451–460

Lin KL, Chang WC, Lin DF, Luo HL, Tsai MC (2008) Effect of nano-SiO2 and different ash particle sizes on sludge ash-cement mortar. J Environ Manag 88:708–714

Liu J, Qiu Z, Huang W (2015) Novel latex particles and aluminum complexes as potential shale stabilizers in water-based drilling fluids. J Pet Sci Eng 135:433–441

Liu F, Darjani S, Akhmetkhanova N, Maldarelli C, Banerjee S, Pauchard V (2017) Mixture effect on the dilatation rheology of Asphaltenes-Laden interfaces. Langmuir 33(8):1927–1942

Madkour TM, Fadl S, Dardir MM, Mekewi MA (2016) High performance nature of biodegradable polymeric nanocomposites for oil-well drilling fluids. Egypt J Pet 25:281–291

Mahmoud O, Nasr-El-Din HA, Vryzas Z, Kelessidis VC (2016) Nanoparticle-based drilling fluids for minimizing formation damage in HP/HT applications. In: SPE international conference and exhibition on formation damage control 2016; SPE-178949-MS

Mahmoud O, Nasr-El-Din HA, Vryzas Z, Kelessidis VC (2017) Characterization of filter cake generated by nanoparticle-based drilling fluid for HP/HT applications. In: SPE international conference on oilfield chemistry. Society of Petroleum Engineers

Moghadam TF, Azizian S (2014) Effect of ZnO nanoparticles on the interfacial behavior of anionic surfactant at liquid/liquid interfaces. Colloids Surf A: Physicochem Eng Aspects 457:333–339. https://doi.org/10.1016/j.colsurfa.2014.06.009

Moghaddam RN, Bahramian A, Fakhroueian Z, Karimi A, Arya S (2015) Comparative study of using nanoparticles for enhanced oil recovery: wettability alteration of carbonate rocks. Energy Fuel 29:2111–2119

Mohajeri A, Rashidi A, Jozani KJ, Khorami P, Amini B, Parviz D, Kalbasi M (2010) Hydrodesulphurization nanocatalyst, its use and a process for its production. U.S. Patent No. 20100167915

Mohammadi MS, Moghadasi J, Naseri S (2014) An experimental investigation of wettability alteration in carbonate reservoir using γ-Al2O3. Nanoparticles 3(2):18–26

Mokhatab S, Fresky MA, Islam MR (2006) Applications of nanotechnology in oil and gas E&P. J Pet Technol Online 58:48

Mozaffari S, Tchoukov P, Mozaffari A, Atias J, Czarnecki J, Nazemifard N (2016) Capillary driven flow in nanochannels: application to heavy oil rheology studies. Colloids Surf A Physicochem Eng Asp 513:178–187

Mozaffari S, Li W, Thompson C, Ivanov S, Seifert S, Lee B, Kovarik L, Karim AM (2018a) Ligand-mediated nucleation and growth of palladium metal nanoparticles. J Vis Exp 136:e57667. https://doi.org/10.3791/57667

Mozaffari A, Sharifi-Mood N, Koplik J, Maldarelli C (2018b) Self-propelled colloidal particle near a planar wall: a Brownian dynamics study Phy Rev. Fluids 3:014104

Mozaffari S, Li W, Dixit M, Seifert S, Lee B, Kovarik L, Mpourmpakis G, Karim AM (2019) The role of nanoparticle size and ligand coverage in size focusing of colloidal metal nanoparticles. Nanoscale Adv 1:4052–4066

Munshi AM, Singh VN, Kumar M, Singh JP (2008) Effect of nanoparticle size on sessile droplet contact angle. J Appl Phys 103(8):084315. https://doi.org/10.1063/1.2912464

Muraza O, Galadima A (2015) Aquathermolysis of heavy oil: a review and perspective on catalyst development. Fuel 157:219–231

Nasser J, Jesil A, Mohiuddin T, Ruqeshi M, Devi G, Mohataram S (2013) Experimental investigation of drilling fluid performance as nanoparticles. World J Nano Sci Eng 3:57–61

Nazari A, Azimzadegan T (2012) Prediction the effects of ZnO2 nanoparticles on splitting tensile strength and water absorption of high strength concrete. Mater Res 15:440–454

Nazari A, Riahi R (2010a) The effect of TiO2 on flexural damage of self-compacting concrete. Int J Damage Mech 20:1049–1072

Nazari A, Riahi S (2010b) The effects of ZrO2 nanoparticles on physical and mechanical properties of high strength self compacting concrete. Mater Res 13:551–556

Nazari A, Riahi S (2011a) TiO2 nanoparticles effects on physical, thermal and mechanical properties of self compacting concrete with ground granulated blast furnace slag as binder. Energy Build 43:995–1002

Nazari A, Riahi S (2011b) Al2O3 nanoparticles in concrete and different curing media. Energy Build 43:1480–1488

Nazari A, Riahi S (2011c) The effects of ZrO2 nanoparticles on properties of concrete using ground granulated blast furnace slag as binder. J Compos Mate 46:1079–1090

Nazari A, Riahi S (2011d) Effects of CuO nanoparticles on microstructure, physical, mechanical and thermal properties of self-compacting cementitious composites. J Mater Sci Technol 27:81–92

Nazari A, Riahi S (2012) Computer-aided prediction of the Al2O3 nanoparticles’ effects on tensile strength and percentage of water absorption of concrete specimens. Neural Comput Appl 21:1651–1667

Nili M, Ehsani A (2015) Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater Des 75:174–183

Pandya HN, Parikh SP, Shah M (2019) Comprehensive review on application of various nanoparticles for the production of biodiesel. Energy Sources Part A: Recovery Util Environ Effects. https://doi.org/10.1080/15567036.2019.1648599

Patel M, Patel J, Pawar Y, Patel N, Shah M (2020a) Membrane-based downhole oil–water separation (DOWS) technology: an alternative to hydrocyclone-based DOWS. J Pet Explor Prod Technol. https://doi.org/10.1007/s13202-020-00848-x

Patel H, Prajapati D, Mahida D, Shah M (2020b) Transforming petroleum downstream sector through big data: a holistic review. J Petrol Explor Prod Technol. https://doi.org/10.1007/s13202-020-00889-2

Peng B, Tang J, Luo J, Wang P, Ding B, Tam KC (2017) Applications of nanotechnology in oil and gas industry: progress and perspective. Can J Chem Eng 96(1):91–100. https://doi.org/10.1002/cjce.23042

Piantanida M, Veneziani M, Fantoni RF, Mickelson W, Milgrome O, Sussman A, et al (2013) An innovative wireless H2S sensor based on nanotechnology to improve safety in oil and gas facilities. In: SPE 166544 presented at the SPE offshore Europe oil and gas conference and exhibition, September 3–6, Aberdeen, UK

Ponmani S, Nagarajan R, Sangwai JS (2016) Effect of nanofluids of CuO and ZnO in polyethylene glycol and polyvinylpyrrolidone on the thermal, electrical, and filtration-loss properties of water-based drilling fluids. Society of Petroleum Engineers. https://doi.org/10.2118/178919-pa

Qing Y, Zenan Z, Deyu K, Rongshen C (2007) Influence of nano-SiO2 addition on particles of hardened cement paste as compared with silica fume. Constr Build Mater 21:539–545

Rafiee E, Rezaei S (2016) Deep extractive desulfurization and denitrogenation of various model oils by H3 + nPMo12– nVnO40 supported on silica-encapsulated γ-Fe2O3 nanoparticles for industrial effluents applications. J Taiwan Inst Chem Eng 61:174–180. https://doi.org/10.1016/j.jtice.2015.11.027

Rahmani AR, Bryant SL, Huh C, Ahmadian M, Zhang W, Liu QH (2015) Characterizing reservoir heterogeneities using magnetic nanoparticles. In: SPE 17319 MS presented at the SPE reservoir simulation symposium, February 23–25, Houston, Texas, USA

Rezvani H, Khalilnezhad A, Ganji P, Kazemzadeh Y (2018) How ZrO2 nanoparticles improve the oil recovery by affecting the interfacial phenomena in the reservoir conditions? J Mol Liq 252:158–168. https://doi.org/10.1016/j.molliq.2017.12.138

Riahi S, Nazari A (2011) Compressive strength and abrasion resistance of concrete containing SiO2 and CuO nanoparticles in different curing media. Sci China Technol Sci 54:2349–2357

Roustaei A, Moghadasi J, Bagherzadeh H, Shahrabadi A (2012) An experimental investigation of polysilicon nanoparticles’ recovery efficiencies through changes in interfacial tension and wettability alteration. In: SPE international oilfield nanotechnology conference and exhibition. Noordwijk, the Netherlands

Roustaei A, Saffarzadeh S, Mohammadi M (2013) An evaluation of modified silica Nanoparticles’ efficiency in enhancing oil recovery of light and intermediate oil reservoirs. Egypt J Pet 22:427–433

Sadeghalvaad M, Sabbaghi S (2015) The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol 272:113–119

Saien J, Moghaddamnia F, Bamdadi H (2013) Interfacial tension of methylbenzene–water in the presence of hydrophilic and hydrophobic alumina nanoparticles at different temperatures. J Chem Eng Data 58(2):436–440. https://doi.org/10.1021/je3011584

Sengupta S, Kumar A (2013) Nano-ceramic coatings-a means of enhancing bit life and reducing drill string trips. Paper IPTC-16474eMS. In: Presented at international petroleum technology conference, Beijing, China

Shah A, Shah M (2020) Characterisation and bioremediation of wastewater: a review exploring bioremediation as a sustainable technique for pharmaceutical wastewater. Groundw Sustain Dev 11:100383. https://doi.org/10.1016/j.gsd.2020.100383

Shah S, Shah M, Shah A, Shah M (2020) Evolution in the membrane-based materials and comprehensive review on carbon capture and storage in industries. Emergent Mater. https://doi.org/10.1007/s42247-020-00069-2

Shakib JT, Kanani V, Pourafshary P (2016) Nano-clays as additives for controlling filtration properties of water–bentonite suspensions. J Petrol Sci Eng 138:257–264

Sikora P, Horszczaruk E, Cendrowski K, Mijowska E (2016) The influence of nano-Fe3O4 on the microstructure and mechanical properties of cementitious composites. Nanoscale Res Lett 11(1):182

Song K, Wu Q, Li M-C, Wojtanowicz AK, Dong L, Zhang X et al (2016) Performance of low solid bentonite drilling fluids modified by cellulose nanoparticles. J Nat Gas Sci Eng 34:1403–1411

Srivatsa JT, Ziaja MB (2012) An experimental investigation on use of nanoparticles as fluid loss additives in a surfactant—polymer based drilling fluid. In: International petroleum technology conference, pp 2436–2454

Sudhakar C (1998) Selective hydrodesulfurization of cracked naphtha using novel catalysts. U.S Patent No. 5770046

Suleimanov BA, Ismailov FS, Veliyev EF (2011) Nanofluid for enhanced oil recovery. J Pet Sci Eng 78(2):431–437. https://doi.org/10.1016/j.petrol.2011.06.014

Taraghikhah S, Kalhor Mohammadi M, Tahmasbi Nowtaraki K (2015) Multifunctional nanoadditive in water based drilling fluid for improving shale stability. In: International petroleum technology conference, 2015; IPTC-18323-MS

Thakkar A, Raval A, Chandra S, Shah M, Sircar A (2019) A comprehensive review of the application of nano-silica in oil well cementing. Petroleum. https://doi.org/10.1016/j.petlm.2019.06.005

Tian Y, Wu Y, Wang Z, Lin Y, Luo P, Guo Q (2019) Fe3O4/poly (acrylic acid) nanoparticles as modifiers for improving rheological and filtration properties of water-based drilling fluids. J Macromol Sci Part A. https://doi.org/10.1080/10601325.2019.1578619

Timofeeva EV, Routbort JL, Singh D (2009) Particle shape effects on thermophysical properties of alumina nanofluids. J Appl Phys 106(1):014304

Turkenburg D, Chin PTK, Fischer H (2018) Use of modified nanoparticles in oil and gas reservoir management. In: SPE 157120 MS presented at the SPE international oilfield nanotechnology conference and exhibition, June 12– 14, Noordwijk, The Netherlands (2012)

Vryzas Z, Zaspalis V, Nalbantian L, Mahmoud O, Nasr-El-Din HA, Kelessidis VC (2016) A comprehensive approach for the development of new magnetite nanoparticles giving smart drilling fluids with superior properties for HP/HT applications. In: International petroleum technology conference. https://doi.org/10.2523/18731-ms

Wang Z (2015) Impact toughness, dry shrinkage and permeability resistance properties of multi-walled carbon nanotubes reinforced cement composites. J Adv Microsc Res 10(1):73–77

Wasan DT, Nikolov AD (2003) Spreading of nanofluids on solids. Nature 423(6936):156–159

Wasan D, Nikolov A, Kondiparty K (2011) The wetting and spreading of nanofluids on solids: role of the structural disjoining pressure. Curr Opin Colloid Interface Sci 16(4):344–349. https://doi.org/10.1016/j.cocis.2011.02.001

Wei L, Hua ZJ, Hua QJ (2007) Application of nano-nickel catalyst in the viscosity reduction of Liaohe extra-heavy oil by aquathermolysis. J Fuel Chem Technol 35:176–180

William JKM, Ponmani S, Samuel R, Nagarajan R, Sangwai JS (2014) Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J Pet Sci Eng 117:15–27

Wong I, Loh KJ, Wu R, Garg N (2015) Effects of ultra-low concentration of carbon nanotubes on the electromechanical properties of cement paste. In: Nanotechnology in construction. Springer, New York, pp 371–376

Yu H, Kotsmar C, Yoon KY, Ingram DR, Johnston KP, Bryant SL, Huh, C (2010) Transport and retention of aqueous dispersions of paramagnetic nanoparticles in reservoir rocks. In: SPE Improved Oil Recovery Symposium. https://doi.org/10.2118/129887-ms

Yu HS, He JB (2015) Fracture toughness and durability performance of highly dispersed multi-walled carbon nanotubes reinforced cement-based composites. J Adv Microsc Res 10(1):14–19

Zargartalebi M, Barati N, Kharrat R (2014) Influences of hydrophilic and hydrophobic silica nanoparticles on anionic surfactant properties: interfacial and adsorption behaviors. J Pet Sci Eng 119:36–43

Zhang R, Cheng X, Hou P, Ye Z (2015) Influences of nano-TiO2 on the properties of cement-based materials: hydration and drying shrinkage. Constr Build Mater 81:35–41

Zhou B (2007) Nanotechnology in catalysis vol 3. Springer, New York. doi:10.1007/978-0-387-34688-5

Acknowledgements

The authors are grateful to the School of Petroleum Technology and School of Technology, Pandit Deendayal Petroleum University, for the permission to publish this research.

Author information

Authors and Affiliations

Contributions

All the authors make substantial contribution in this manuscript. JS, VS, KD and MS participated in drafting the manuscript. JS, VS and KD wrote the main manuscript; all the authors discussed the results and implication on the manuscript at all stages.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shingala, J., Shah, V., Dudhat, K. et al. Evolution of nanomaterials in petroleum industries: application and the challenges. J Petrol Explor Prod Technol 10, 3993–4006 (2020). https://doi.org/10.1007/s13202-020-00914-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-020-00914-4