Abstract

Coagulation is a primary and cost effective process in water treatment plants. Under optimum conditions, not only it effectively removes turbidity but also results in reduced sludge volume and subsequently minimizes sludge management costs. Highly turbid water from streams, canals, rivers and rain run offs was run through jar test for turbidity removal. The brown water with 250NTU turbidity when coagulated with alum and assorted coagulants proved that maximum turbidity removal was witnessed using alum dose of 0.25 g/l at ph 6 with a sedimentation time of 30 min.

Similar content being viewed by others

Introduction

Water is called turbid when it appears cloudy or muddy with suspended solids in it. The solid particles in turbid water are so small that they do not settle down, but stay suspended in the water. Turbidity could be described as an expression of optical property that would cause light to scatter and get absorbed rather than transmit with no change in direction (Eaton et al. 2005). Materials that cause turbidity in water may include clay, silt along with microorganisms, they usually impart cloudy appearance to water and may associate with some other aesthetic concerns such as color odor or taste. Turbidity becomes a major concern as most of the health risks are associated with suspended organic matter, bacteria and other microorganisms. As a result of these risks, turbidity removal continues to be a prime objective of coagulation operation (Davis and Edwards 2014).

Water from floods and rain run offs is muddy and contains lot of turbidity. With the addition of coagulants, turbidity can be removed and thus clear water may be obtained. However, addition of inorganic coagulants to remove turbidity may lead to adverse impacts on human health (Simate et al. 2012), and hence the treated water may not be completely fit for drinking purposes. This clear treated water could thus be used for washing purposes once it is free of debris and turbidity, reducing the pressure on clean drinking water as a resource.

Higher efficiency to treat turbid water has made inorganic chemicals favorite coagulants. Not only are they low priced but are also readily available (Duan and Gregory 2003). In water, most of the particles are negative charged, to neutralize the charge a positive ion (cation) may be used as a coagulant. Potassium hydroxide contributes a mono-valent ion, K+. Calcium hydroxide gives a divalent ion, Ca2+. Aluminum coagulants give trivalent aluminum ions, Al3+. According to Schultz in 1882 and Hardy in 1900, higher the charge of cation, more effective is charge neutralization.

Alum is one of the most widely used coagulants in the water treatment industry (Benschoten and Edzwald 1990). For water and wastewater treatment, the coagulants used more frequently are the inorganic salts of aluminum. When added to water, Al ions hydrolyze rapidly and form a range of metal hydrolysis species (Jiang 2015). These cationic species adsorb onto the negatively charged particles and neutralize the charge. In this mechanism, particles get destabilized and aggregation occurs (Yukselen and Gregory 2004).

Coagulation depends on coagulant dosage and also the ph. Almost all of the colloids in water are negatively charged and because of electrical repulsion they may remain stable. Destabilization could be made by addition of salts or cations that will interact with negative colloids to neutralize their charge (Duan and Gregory 2003). Upon hydrolysis, aluminum hydroxide precipitate is formed, this precipitate sweeps the colloidal particles from the suspension and is called the sweep-floc coagulation. Since it does not involve any charge reversal this is more popularly used in water treatment (Kim et al. 2001).

This paper aims at comparing the efficiency of Alum with other assorted coagulants such as potassium carbonate, potassium hydroxide, calcium oxide, sodium carbonate at varying pH, in removing turbidity in muddy water from streams, canals, rivers and rain run offs. A precise coagulant dose is required for charge neutralization, overdosing can lead to charge reversal and restabilization of particles.

Materials and methods

Water from rivers, canals and rain run offs varies widely in its turbidity. Samples were taken from river Ravi in Lahore and from the canal which bisects the city. In addition, water was also collected off the streets as rain run offs. Water collected from all these sources varied widely in its turbidity. It was for this purpose, water from all these sources was mixed together to get a homogenous mixture. Equal proportions of water from all these sources was mixed. It was then allowed to sit in storage tank for 24 h. This acted like sedimentation tank allowing for most debris and heavy particles to settle by gravitational force. The supernatant was simply filtered with whatmann’s filter paper no. 42 using a funnel. The idea of filtering the sample water was to free it from any heavy particles present in water. This filtered water with dark brown color possessed the following characteristics:

- pH:

-

7–7.3

- Color:

-

dark brown

- Turbidity, NTU:

-

250

- TDS, mg/l:

-

1900

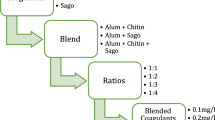

Coagulation was conducted using jar method with different coagulant dose and at different pHs. 0.1 N HCl and 0.1 N NaOH were used to adjust the pH of sample water. The coagulants used were,

- Potash alum (dodecahydrate) KAl (SO4)2. 12H2O CAS#:

-

10043-67-1

- Potassium carbonate (salt of tartar) K2CO3 CAS#:

-

584-08-7

- Potassium hydroxide (caustic potash) KOH CAS#:

-

14459-95-1

- Calcium oxide (Quicklime) CaO CAS#:

-

1305-78-8

- Sodium Carbonate (soda ash) Na2CO3 CAS#:

-

497-19-8

As coagulant was added, stirring speed was maintained at 100 rpm for 2 min and followed by a slow stirring speed of 40 rpm for 10 min, (Choy 2016). Beakers were then allowed to sit for sedimentation. After 30 min, the treated samples were tested for turbidity, pH and TDS. All the experiment and sample analysis were performed in triplicate at room temperature of 25 ± 1 °C.

Results and discussion

In water, aluminium salts hydrolyze and give a variety of products including cationic species, which can adsorb on negative charged particles, and thus neutralize their charge. The particles get destabilized and aggregation occurs. Over dozing of coagulant leads to charge reversal and particles start restabilizing. A higher than the optimum dose of coagulant thus results in less turbidity removal. (Yukselen and Gregory 2004).

As evidenced with Fig. 3, turbidity removal is maximum at an optimized dose of alum 0.25 g/l and when the dose is increased turbidity tends to reappear due to charge reversal. After having had run the samples with varying amounts of coagulants, it was observed that maximum turbidity was removed when alum was added at 0.5 g/l at a ph of 7 with 10 NTU on turbidity meter (Figs. 1, 2). However, when ph dropped to 6, 10 NTU was witnessed at alum concentration of 0.25 g/l (Fig. 3). As pH was further dropped to 4, again a higher dosage of alum was required to get a clearer solution (Figs. 4, 5). Similar kind of result was observed using calcium oxide as coagulant. Maximum turbidity removal was witnessed but at a higher dose compared to alum. At both ph 6 and 4, it took 1 g/l of CaO to give 10 NTU on the scale. The pH not only affects the surface charge of coagulants, but also affects the stabilization of the suspension. The effectiveness of coagulants used gets affected with increase or decrease in pH (Saritha et al. 2017).

Assorted coagulants like potassium carbonate, potassium hydroxide, calcium oxide, sodium carbonate were used to treat muddy water at ph 7, 6 and 4. Turbidity removal was observed but just to an extent, with 25–100 NTU being the range. TDS tends to drop when extra coagulant dose is used, but with alum it drops sharply making it a preferred choice over other coagulants (Fig. 6).

The resultant pH of treated water also exhibits different patterns for alum as compared to other coagulants. When ph of sample water was maintained at 7, after coagulation with alum the resultant ph was seen closer to 6 whereas with other coagulants it was witnessed from 9 to 11.5 (Fig. 7). Even at lower pH of sample water, the resultant ph of treated water still remains higher because of strong alkaline nature of coagulants (Figs. 8, 9).

Conclusion

While comparing the resultant pH of coagulation treated water, it was observed that alum exhibits a different behavior compared to other coagulants. pH of treated water tends to stay stable when alum was used as coagulant, whereas when treated with other coagulants, the pH of treated water increases tremendously. This is because of higher alkaline nature of coagulants. In this series of studies, it was revealed that alum works quite effectively in removing turbidity in muddy water, and its efficiency gets improved with low pH at or around 6. When compared with other coagulants, their effectiveness is not as good to remove turbidity in muddy water. Furthermore, coagulants being highly alkaline in nature, turn the sample water alkaline with high pH. The brown water with 250NTU turbidity when coagulated with alum and assorted coagulants proved that maximum turbidity removal was witnessed using alum dose of 0.25 g/l at ph 6 with a sedimentation time of 30 min.

References

Choy SY (2016) Performance of conventional starches as natural coagulants for turbidity removal. Ecol Eng 94:352–364

Davis CC, Edwards M (2014) Coagulation with hydrolyzing metal salts: mechanisms and water quality impacts. Crit Rev Environ Sci Technol 44(4):303–347

Duan J, Gregory J (2003) Coagulation by hydrolysing metal salts. Adv Colloid Interface Sci 100:475–502

Eaton AD, Clesceri LS, Rice EW, Greenberg AE (2005) Standard methods of the examination of water and wastewater, 21st edn. American Public Health Association, Washington

Jiang JQ (2015) The role of coagulation in water treatment. Curr Opin Chem Eng 8:36–44

Kim SH, Moon BH, Lee HI (2001) Effects of pH and dosage on pollutant removal and floc structure during coagulation. Micro Chem J 68(2–3):197–203

Saritha V, Srinivas N, Srikanth N, Vuppala NS (2017) Analysis and optimization of coagulation and flocculation process. Appl Water Sci 7(1):451–460

Simate GS, Iyuke SE, Ndlovu S, Heydenrych M, Walubita LF (2012) Human health effects of residual carbon nanotubes and traditional water treatment chemicals in drinking water. Environ Int 39:38–49

Van Benschoten J, Edzwald JK (1990) Chemical aspects of coagulation using aluminum salts. I. Hydrolytic reactions of alum and polyaluminum chloride. Water Res 24:1519–1526

Yukselen MA, Gregory J (2004) The effect of rapid mixing on the break-up and re-formation of flocs. J Chem Technol Biotechnol 79(7):782–788

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Malik, Q.H. Performance of alum and assorted coagulants in turbidity removal of muddy water. Appl Water Sci 8, 40 (2018). https://doi.org/10.1007/s13201-018-0662-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-018-0662-5