Abstract

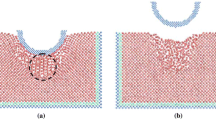

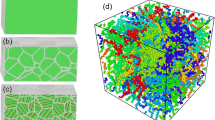

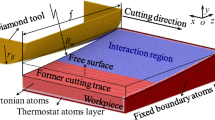

Nano-processes are gradually becoming more important than ever to realize the nano-metric cutting or nano-material formation. Although FEM and molecular dynamics (MD) are popular two analytical methods, they have their own limitations as used for nanoprocess simulation such as immense calculation time cost of MD, inappropriate governing equations of FE. To compensate the drawbacks of both methods and meet the demands on nanotechnology, multi-scale modeling approach is anticipated to provide a powerful analytical tool assuring materials simulation across length/time scale. In this paper one novel multi-scale simulation method combining the material point method (MPM) and MD by handshaking approach is proposed for nano-processes, i.e. nano-metric cutting and thin film formation. Quantitative assessment items: adhesion/cutting force, flatness and densification coefficient, etc. are provided to avoid drawbacks of current qualitative manner. Finally, various simulations are conducted to validate the efficiency of proposed multi-scale simulation approach and clarify the mechanism of nano-processes.

Similar content being viewed by others

References

Müller G., Deimal P.P., Hellmich W., Wagner C.: Sensor fabrication using thin film-on-silicon approaches. Thin Solid Films 296, 157 (1997)

Hwang N., Hahan J., Yoon D.: Charged cluster model in the low pressure synthesis of diamond. J. Crystal Growth 162, 55–68 (1996)

Chen H.W., Hagiwara I., Huang T., Zhang D.W.: Theoretical study on thin-film formation by parallel molecular dynamics simulation. Synth. Metals 155, 652–656 (2005)

Chen H., Hagiwara I., Zhang D., Huang T.: Parallel molecular dynamics simulation on thin film formation. J. Crystal Growth 276, 281–288 (2005)

Dornfeld D., Min S., Takeuchi Y.: Recent advances in mechanical micromachining. Ann CIRP 55(2), 745–768 (2006)

Yan J., Strenkowski J.: A finite element analysis of orthogonal rubber cutting. J. Mater. Process. Technol. 174(1–3), 102–108 (2006)

Mamalis A.G., Horvath M., Branis A.S., Manolakos D.E.: Finite element simulation of chip formation in orthogonal metal cutting. J. Mater. Process. Technol. 110, 19–27 (2001)

Simoneau A., Ng E., Elbestawi M.A.: Chip formation during microscale cutting of a medium carbon steel. Int. J. Mach. Tools Manuf. 46, 467–481 (2006)

Shiari B., Miller R.E., Klug D.D.: Multiscale simulation of material removal processes at the nanoscale. J. Mech. Phys. Solids 55, 2384–2405 (2007)

Cheng K., Luo X., Ward R., Holt R.: Modelling and simulation of the tool wear in nanometric cutting. Wear 255(7–12), 1427–1432 (2003)

Komanduri R., Chandrasekaran N., Raff L.M.: MD simulation of nanometric cutting of single crystal aluminium-effect of crystal orientation and direction of cutting. Wear 242, 60–88 (2000)

Komanduri R., Chandrasekaran N., Raff L.M.: Orientation effects in nanometric cutting of single crystal materials: an MD simulation approach. Ann. CIRP 48, 67–72 (1999)

Rafii-Tabar H., Hua L., Cross M.: A multi-scale atomistic continuum modelling of crack propagation in a two-dimensional macroscopic plate. J. Phys. Condens. Matter 10, 2357–2387 (1998)

Liu X., Devor R.E., Kapoor S.G. et al.: The mechanics of machining at the microscale: assessment of the current state of the science. Trans. ASME J. Manuf. Sci. Eng. 126, 666–678 (2004)

Bardenhagen S.G.: Energy conservation error in the material point method for solid mechanics. J. Comput. Phys. 180, 383–403 (2002)

Daw M.S., Baskes M.I.: Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. Lett. 29, 6443–6453 (1984)

Jackson M.J.: Micro and Nanomanufacturing. Springer, Berlin (2007)

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Chen, H., Hagiwara, I. & Tieu, A.K. A seamless coupling between molecular dynamics and material point method. Japan J. Indust. Appl. Math. 28, 55–67 (2011). https://doi.org/10.1007/s13160-011-0026-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13160-011-0026-0