Abstract

Copper(I) oxide (Cu2O) was electrochemically deposited on fluorine-doped tin oxide (FTO) glass electrode and covered with a thin layer of poly(3,4-ethylenedioxythiophene) polystyrene sulfonate (PEDOT:PSS). The electrode was studied in the photoelectrocatalytic reduction of CO2. Methanol was obtained as the major product with a concentration of 460 μmol L−1 with a photoconversion yield of 12% after 60 min of reaction under the conditions of UV-Vis (125 W Hg high pressure lamp) and application of 0.0 V vs Ag/AgCl in 3.0 mol L−1 KCl in buffer sodium carbonate/sodium bicarbonate 0.1 mol L−1 saturated with CO2 gas. The PEDOT:PSS has led to a significant improvement in CO2 conversion due to rapid transfer of photogenerated holes. Consequently, the thin layer of PEDOT:PSS also reduces the photooxidation of Cu2O to CuO. The Cu2O/PEDOT:PSS photocatalytic system was found to have excellent photostability. Similar yield of alcohol was observed after reusing the catalyst six times.

Graphical Abstract

Similar content being viewed by others

Introduction

The world has an ever-increasing demand for energy to carry out fundamental activities such as transportation, industrial processes, food, and heating. Most of this energy demand is satisfied by use of fossil fuels, which leads to CO2 and other greenhouse gases (GHG) emissions responsible for Earth’s climate change [1, 2]. To overcome these issues, there is a high demand for the development of renewable energy resources and CO2 reduction technologies. Among several alternatives, conversion of CO2 into value-added products and/or fuels is an attractive option [3]. Technologies such as biocatalysis, thermocatalysis, electrocatalysis [2, 4], photocatalysis, and photoelectrocatalysis are currently being intensively pursued [2, 5,6,7,8]. Among these processes, photoelectrocatalytic reduction of CO2, in particular, has received great interest in recent years, due to combination of simple and easy to build systems, ability to control the conditions required for the CO2 reduction to alcohols, high selectivity, and easy scale-up.

A p-type semiconductor is commonly used in the photoelectrocatalytic process, where CO2 reduction occurs by photogenerated electrons that are promoted from the valence band to the conduction band under proper illumination. Among the p-type semiconductors, Cu2O is of special interest because of its narrow band gap (Eg = 2.0 eV) that allows for absorption of visible light, conduction, and valence bands positions that are appropriate for CO2 reduction [3, 9,10,11,12]; its known high selectivity in the photoreduction of CO2 to methanol [4, 9, 13,14,15,16]; and its low cost and low toxicity. However, the use of Cu2O for conversion of CO2 to methanol is limited by the lack of stability due to photocorrosion and high recombination rate of photogenerated charge carriers [11, 12, 17]. To overcome these limitations and improve the efficiency of its photoelectrocatalytic activity, the construction of heterojunction with n-type semiconductor such as TiO2, ZnO, Bi2O3 [18,19,20,21,22,23], noble metals (Au, Ag and Cu) [24, 25], and carbonaceous materials (graphene, CNT, rGO) [12, 17, 26] has been reported.

Stabilization of Cu2O by coating with ultrathin films such as nitrogen-containing polymers or oligomers [14, 27,28,29] has been reported. Modification of Cu2O surface with nafion was also studied [9]. The authors indicated that outermost nafion layer on transparent conducting oxide (TCO/Cu2O) facilitated the adsorption of CO2, which led to higher cathodic photocurrent, thus better overall photoelectrochemical conversion efficiency, and the reported system, which consisted of the oxide semiconductors Cu2O and TiO2 covered with a nafion film, exhibited remarkable stability with time. Other conducting polymer films such as polyaniline (PANI) and polypyrrole (PPy) were also studied [30, 31].

Another polymer widely used in photoelectrochemical studies is the 3,4-ethylenedioxythiophene:polystyrene sulfonate (PEDOT:PSS). This polymer is a good polyelectrolyte with high conductivity (10 S cm−1) and stability [32,33,34] with a band gap of 1.6 eV and LUMO and HOMO located at − 1.32 and 0.28 eV, respectively. Mardiansyah et al. [35] and Sun et al. [36] describe the use of PEDOT:PSS as a transparent protective layer that prevents the photocorrosion of Cu2O nanowires in photovoltaic solar cells without affecting the performance of the Cu2O. The PEDOT:PSS layer improves the performance of photovoltaic solar cells, because it allows fast transfer of photogenerated electrons reducing the recombination process rate [30, 31, 37]. Another interesting feature of PEDOT:PSS was shown by Lee et al. and Hong and Huh that indicates the good ability of this polymer to adsorb CO2 in its structure [30, 38]. This characteristic is interesting to CO2 reduction, since the electrons photogenerated by Cu2O under irradiation, can be quickly transferred to CO2 molecules trapped in the PEDOT:PSS. The process could favor the performance of the conversion of CO2 in compounds of high added value.

The present work reports the fabrication of the Cu2O film on FTO glass substrate coated with a thin film PEDOT:PSS polymer. The electrode was designed in order to amplify the optical property, electron transfer suitability, stability of Cu2O film, and better adsorption of CO2 on the surface of the electrode. In addition, the new electrode assay (FTO/Cu2O/PEDOT:PSS) is tested to increase the reduction efficiency of CO2 to methanol by the photoelectrocatalytic process.

Experimental

Materials

All reagents, solvents, and electrolytes used in this study were of analytical grade: Copper(II) sulfate pentahydrate (CuSO4.5H2O, 98% Sigma-Aldrich), sodium citrate (C6H5Na3O7.2H2O, 99% Merck), potassium hydroxide (KOH, 98% Sigma-Aldrich), sodium sulfate (Na2SO4, Sigma-Aldrich), sodium hydrogen carbonate(NaHCO3 Merck), sodium carbonate (Na2CO3, Merck), PEDOT:PSS 4% m/v (Sigma-Aldrich), dimethylsulfoxide ((CH3)2SO, Synth), FTO from DyeSol, and resistivity 7 Ω/sq. Ultrapure water was used for the preparation of all the solutions. For all electrochemical measurement, Ag/AgCl in 3 mol L−1 KCl was used as reference electrode.

Preparation of FTO/Cu2O/PEDOT:PSS Electrode

The synthesis of the FTO/Cu2O/PEDOT:PSS electrode was carried out by using the following procedure. Firstly, a thin film of Cu2O was electrodeposited onto FTO glass substrate using a potentiostat/galvanostat PGSTAT 302 N Autolab system Metrohm (Herisau, Switzerland). For this, a solution containing 0.05 mol L−1 CuSO4.5H2O and 0.125 mol L−1 C6H5Na3O7.2H2O was prepared, and the pH of the solution was adjusted to pH 12, by adding drops of a solution 9 mol L−1 KOH. The Cu2O thin film was electrodeposited onto the FTO substrate using an electrochemical cell with capacity of 50 mL, containing three electrodes (FTO substrate working, dimensionally stable anode commercial (DSA®) counter, and Ag/AgCl reference electrodes). Cyclic voltammograms (5 successive cycles) were recorded immersing the electrode in the cell containing 30 mL of solution and scanned under potential window of + 0.3 V to − 1.0 V vs Ag/AgCl, at scan rate of 10 mV s−1 and T = 65 °C. Afterwards, the thickness of the Cu2O film deposited on the surface of FTO was controlled by chronoamperometry technique that used a constant applied potential of − 0.55 V vs Ag/AgCl and different times (10, 20, and 30 min). The FTO/Cu2O electrodes were washed in water and dried at room temperature for 60 min. Deposits of the conductor polymer onto FTO/Cu2O electrode were carried out by drop coating technique.

A solution containing 500 μL of PEDOT:PSS 4% m/v and 1500 μL of DMSO was prepared under stirring of 2 h. Then, 100 μL of this solution was deposited onto the FTO/Cu2O electrode surface. To form PEDOT:PSS film, the electrode was dried at 65 °C in an EDG muffle furnace (model 3P-S, São Paulo, Brazil) for 1 h.

Electrode Characterization

FTO/Cu2O/PEDOT:PSS electrode was characterized by field emission gun-scanning electron microscopy (FEG-SEM) using a JEOL 7500F microscope (Tokyo, Japan).

CO2 adsorption on the electrode surface with and without PEDOT:PSS was studied by Fourier transform infrared spectroscopy (FTIR). The study was carried out in a Vertex 70 BRUKER, spectrophotometer with the ATR mode (Ettlingen, Germany).

The optical properties were determined in the 200–800 nm range by diffuse reflectance spectroscopy using a Cary 60 UV/Vis Agilent Technologies spectrometer (Santa Clara, CA, USA) equipped with an external remote diffuse reflectance accessory probe Barrelino™, Harrick Scientific (Pleasantville, NY, USA) calibrated with a Spectralon standard (Labsphere USRS-99-020, 99% reflectance).

The photoelectrocatalytic activity was studied using a potentiostat/galvanostat PGSTAT 302 N Autolab system Metrohm, (Herisau, Switzerland) in the dark and under irradiation by linear sweep voltammetry at scan rate of 10 mV s-1.

Photoelectrocatalytic Reduction of CO2

The photoelectrocatalytic reduction of CO2 was investigated in different support electrolytes such as NaHCO3/Na2CO3 buffer, Na2CO3, or Na2SO4 in 0.1 mol L−1 of concentration saturated with CO2 gas for 30 min and a flow of 1 L min−1; this gas was kept constant throughout the experiments. A thermostatized glass reactor (the temperature of the experiments was kept at 30 °C) of 150 mL of capacity containing a quartz tube positioned in the center was used with three electrodes (FTO/Cu2O/PEDOT:PSS (1.5 × 3.5 cm2) working, Ag/AgCl reference, and DSA® commercial (2.0 × 3.5 cm2) counter electrodes) and 120 mL of support electrolyte under magnetic stirred. For irradiation UV-Vis light, a 125 W high pressure mercury lamp was used and positioned inside of the quartz tube in front of the FTO/Cu2O/PEDOT:PSS electrode. The experiments were carried out studying different parameters such as film thickness, supporting electrolyte, and bias potential. Techniques such as photocatalysis (FTO/Cu2O or FTO/Cu2O/PEDOT:PSS electrodes + UV-Vis irradiation), electrocatalysis (FTO/Cu2O/PEDOT:PSS electrode + bias potential), and photoelectrocatalysis (FTO/Cu2O/PEDOT:PSS electrode + UV/Vis irradiation + bias potential) were carried out in triplicate.

The concentration of CO2 dissolved in the solution was determined by total organic carbon (TOC) analysis using a Shimadzu model TOC-VCPN analyzer (Kyoto, Japan), and the concentration of CO2 after 30 min bubbling was of 180 mg L−1. The photoelectrocatalytic experiments were performed in different potentials as − 0.2 V, 0.0 V, and + 0.1 V vs Ag/AgCl using a potentiostat/galvanostat PGSTAT 302 N Autolab system Metrohm, (Herisau, Switzerland) with and without irradiation onto FTO/Cu2O/PEDOT:PSS, and FTO/Cu2O electrode also was used to compare the influence of the PEDOT:PSS deposited onto FTO/Cu2O.

Analysis of Products of Photoelectrocatalytic Reduction of CO2

Methanol and ethanol were identified and quantified by gas chromatography with flame ionization detection (GC-FID) using a Shimadzu 2010 model (Kyoto, Japan). For the analysis of the samples, solid phase microextraction technique (SPME) was used by using fiber coated with divinylbenzene/polydimethylsiloxane (DVB/PDMS) (reference 57329-U) (Supelco, Saint Quentin Fallavier, France) [16, 39, 40]. A Restec Stabilwax chromatographic column consisting of 30 m (Bellefonte, PA, USA) with 0.25 mm internal diameter and 25 μm film thickness was used. Nitrogen was used as gas carrier, at a flow rate of 1.0 mL min−1, and the temperature employed for the injector and detector was 250 °C. The column was heated from 40 to 46 °C at 2 °C min−1 and then was increased to 170 °C at 45 °C min−1 and maintained at this temperature for 4 min. Calibration curves for methanol and ethanol were constructed with a linear relationship from 10 to 1000 μmol L−1 (correlation coefficient r2 = 0.999 for both curves), and the detection limits obtained were 1.11 μmol L−1 and 0.81 μmol L−1 for methanol and ethanol, respectively.

Results and Discussion

Characteristics of the FTO/Cu2O/PEDOT:PSS Electrode

Figure 1 shows SEM images obtained for the FTO/Cu2O electrode (Fig. 1a) and FTO/Cu2O/ PEDOT:PSS electrodes (Fig. 1b). A change in the surface morphology is observed, due to the electrodeposited Cu2O film, with a microstructured appearance, where some crystallites in the form of quadrangular prisms of approximately 1 μm in length are clearly distinguished (Fig. 1c) [14]. For FTO/Cu2O/PEDOT:PSS, the formation of an organic layer on the oxide is observed, and the particles of Cu2O is not distinguished, but the polymer is coating all oxide surface (Fig. 1d).

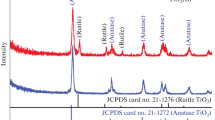

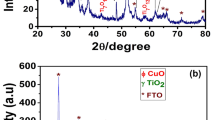

The absorbance spectra obtained for all materials analyzed are shown in Fig. 2a. As expected, FTO/Cu2O semiconductor (black) shows absorption in both UV and visible regions, while the conductive polymer FTO/PEDOT:PSS (red) shows only an absorption band in the UV at 280 nm. In contrast, the FTO/Cu2O/PEDOT:PSS (blue) shows strong broad absorption spread over the entire visible and UV region. FTO/PEDOT:PSS absorbs in UV only, but when coupled to Cu2O catalyst, there is an improvement of the optical properties of the new material.

Linear scan voltammograms (Fig. 2b) were recorded for the FTO/Cu2O/PEDOT:PSS in 0.1 mol L−1 NaHCO3/Na2CO3 buffer solution. The experiments were performed in the dark and under irradiation, in the presence and absence of CO2. The photocurrent increases in relation to the dark conditions at more positive potential than − 0.3 V, while hydrogen evolution starts in − 0.5 V. When CO2 gas is injected in the supporting electrolyte, the photocurrent intensity shows a large wave around 0 and − 0.2 V vs Ag/AgCl attributed to CO2 reduction under irradiation of FTO/Cu2O/PEDOT:PSS. These results suggest that the synthesized material could improve the CO2 reduction at low bias potential [16].

To determine the effect of the polymer on CO2 capture, FTIR measurements were carried out for the FTO/Cu2O and FTO/Cu2O/PEDOT:PSS films before and after CO2 exposure for 12 h (Fig. 3). The vibrational modes of carbon dioxide associated with the νas C=O ν3, ν1, and ν2 bending bands are found in the gas phase CO2 spectrum at 2344, 1388, and 652 cm−1, respectively [41]. According to the literature [42, 43], the peaks at 612 and 652 cm−1 are specifically attributed to Cu(I)-O vibrational mode of the Cu2O phase and Cu2O/PEDOT:PSS, respectively. The bands at 1120 and 1017 cm −1 are also attributed to a vibrational stretching mode of Cu(I)-O bond, which disappear after adsorption of CO2 at Cu2O and Cu2O/PEDOT:PSS, respectively. The bands at 2338 and 2343 cm−1 are assigned to antisymmetric stretching mode of vibration of CO2. Their intensity increased when the films were exposed to CO2, indicating that CO2 is adsorbed on both Cu2O and Cu2O/PEDOT:PSS films.

CO2 Photoelectroreduction at FTO/Cu2O and FTO/Cu2O/PEDOT:PSS Electrodes

The photoelectrocatalytic reduction of dissolved CO2 dissolved in carbonate/bicarbonate buffer 0.1 mol L−1 to methanol at both FTO/Cu2O/PEDOT:PSS and FTO/Cu2O electrodes under irradiation was studied applying 0.0 V of bias potential. The amount of alcohol generated after 60 min is shown in Fig. 4. The methanol is the major product obtained during these experiments using both electrodes. This behavior is evidence that a greater number of charge carriers were generated, probably because there is a shifting of the absorption bands to the visible region in the heterojunction system. As expected, there is prompt photocorrosion of FTO/Cu2O electrode after 30 min of treatment, and the methanol generated is at least 18 times lower when compared to the performance of FTO/Cu2O/PEDOT:PSS electrode. It is well-known that PEDOT:PSS is widely used as hole transport layer [44]. However, when coupled to p-type semiconductor to produce a heterojunction such as Cu2O/PEDOT:PSS, the Schottky barrier and the Fermi level alignment at the organic/inorganic interface give rise to electron transfer from the inorganic semiconductor surface to the organic layer. The positions of HOMO (0.28 eV) and LUMO (− 1.32 eV) of the PEDOT:PSS conductor polymer are located between the orbitals of higher and lower energy of the Cu2O semiconductor with valence band at 0.80 eV and conduction band at − 1.4 eV [11, 34]. Photoexcitation of the Cu2O/PEDOT:PSS heterojunction generates charge carriers in each component, but the electrons and holes photogenerated are conducted to the orbitals LUMO and HOMO of the conductor polymer, respectively. Accordingly, the oxidation of adsorbed water by the holes scavenged can influence in the decreasing of the rate of Cu2O photocorrosion [34]. As demonstrated in Scheme 1, this behavior preserves the heterojunction for a longer time, while the electrons become available to promote CO2 reduction. The CO2 photoreduction occurs in different stages, which involve adsorption, activation, and dissociation of the carbon and oxygen bond. The activation step is particularly challenging because the CO2 molecule is highly stable and inert [16, 18, 45,46,47,48]. This process involves a series of reaction steps and the exchange of a large number of electrons and protons, which makes this process complex and challenging requiring 6 e− and 6 H+ to convert CO2 in methanol.

Influence of Film Thickness and Supporting Electrolyte on the Performance of CO2/Methanol Conversion

To optimize the thickness of Cu2O films for better performance of FTO/Cu2O/PEDOT:PSS, the electrodeposition of Cu2O on FTO for 10 min, 20 min, and 30 min before deposition of PEDOT:PSS film was investigated. Figure 5a shows methanol yield obtained after 1 h of photoelectrocatalytic reduction of CO2 in NaHCO3/Na2CO3 0.1 mol L−1 buffer at FTO/Cu2O/PEDOT:PSS under UV-Vis light irradiation and 0.0 V potential. Maximum photoeletrogeneration of methanol was obtained for thinner films of Cu2O (10 min), that is, 4 and 10 times higher than films obtained at electrodeposition times of 20 and 30 min, respectively. The thickness of PEDOT:PSS was also investigated using different ratios of PEDOT:PSS/DMSO. The best results were obtained for a ratio of 1:3 v/v. The order of addition PEDOT:PSS and Cu2O at FTO was also investigated, and the sandwich of FTO/Cu2O/PEDOT:PSS presented higher stability and also better efficiency, with no evidence of photocorrosion.

The results indicate that higher efficiency was verified for thinner films of both Cu2O and also PEDOT:PSS that seems activated as a protective layer.

The effect of supporting electrolyte on the photoelectrocatalytic performance of the FTO/Cu2O/PEDOT:PSS was also studied for dissolved CO2 in 0.1 mol L−1 of NaHCO3/Na2CO3, Na2CO3, NaHCO3, and Na2SO4. The photoelectrocatalysis experiments carried out during 60 min at 0.0 V and UV-Vis light are compared in Fig. 5b. Highest amount of methanol was produced in the NaHCO3/Na2CO3 buffer electrolyte. This behavior corroborates with literature [49] and can be correlated with the higher solubility of CO2 and higher adsorption at the electrode surface. This is an evidence that in a buffered medium NaHCO3/ Na2CO3, the pH is not greatly altered after saturation with CO2 or during its reduction at electrode surface favoring the solubility of CO2 and stabilizing the formation of radicals CO2 radical.

Photoelectrocatalytic Reduction of Dissolved CO2 at FTO/Cu2O/PEDOT:PSS Electrode: Potential and Stability

Figure 6 a shows the photoelectrocatalytic conversion of CO2 to methanol at FTO/Cu2O/PEDOT:PSS electrode under applied potential of 0.0 V, and UV/visible irradiation was monitored by gas chromatography. Experiments were performed for 60 min in 0.1 mol L−1 sodium carbonate/bicarbonate buffer saturated with CO2. The results were compared to photocatalytic performance using the same electrode under UV-vis irradiation only and electrochemical reduction using only an applied voltage of 0.0 V.

a Methanol formation after 60 min of photocatalysis (UV-Vis), electrocatalysis (E = 0.0 V without UV-Vis irradiation), and photoelectrocatalysis (E = 0.0 V and UV-Vis irradiation) of dissolved CO2 reduction in NaHCO3/Na2CO3 at FTO/Cu2O/PEDOT:PSS. b Methanol generated under 60 min of photoelectrochemical reduction at bias potential of − 0.2 V, 0.0 V, and + 0.1 V vs Ag/AgCl

The electrolysis processes showed only negligible generation of any of the products analyzed. In contrast, photoelectrocatalysis led to production of higher amount of methanol reaching 530 μmol L−1 after 60 min. Taking into consideration that dissolved CO2 in the solution is around 180 ppm [50], methanol production represents 12% of the reduction of CO2. In addition, comparing the performance with photocatalysis, for instance, an increase of 75% is observed, indicating that the bias potential can control the Fermi level of the semiconductors arrangement (FTO/Cu2O/PEDOT:PSS), which promotes steeper band bending that decreases the recombination rate of e−/h+ charge carriers [51].

The role of the applied potential on CO2/methanol conversion was also investigated. Photoelectrocatalytic experiments were carried out in 0.1 mol L−1 sodium carbonate/bicarbonate buffer saturated with CO2 at bias potentials of − 0.2 V, 0.0 V, and + 0.1 V vs Ag/AgCl under UV-Vis light irradiation and 10 °C (Fig. 6b). The results indicate that higher efficiency was reached at 0.0 V. As shown in Eqs. (1)–(3), the reduction of CO2 to CH3OH occurs at positive potentials [18]. At − 0.2 V, the slight decrease in methanol conversion could indicate secondary reactions such as hydrogen production and that CO adsorption as intermediate could take place in the process [52, 53].

Thus, 0.0 V was chosen for further photoelectrocatalysis studies because of good conversion of CO2/CH3OH and high stability of the prepared electrode, since the electrode was not destroyed even after 6 repetition of 60 min.

Photoelectrocatalytic reduction of CO2 to methanol at Cu2O/PEDOT:PSS electrode in 0.1 mol L−1 NaHCO3/Na2CO3 buffer at 10 °C and under UV-Vis light irradiation was monitored for 120 min (Fig. 7). The concentration of methanol increased linearly reaching a maximum of 473 μmol L−1 after 60 min. However, after this period of reaction, a drop of almost half of the maximum achieved production of methanol is observed, obtaining 187 μmol L−1 of methanol in 120 min of reaction.

To assess the stability of the FTO/Cu2O/PEDOT:PSS compared to the FTO/Cu2O electrode, photoelectrocatalytic reduction of dissolved CO2 under optimized conditions was investigated (Fig. 8). Photoelectrolysis carried out at FTO/Cu2O showed only one use with visible damage of the coating after each experiment. However, the results obtained at FTO/Cu2O/PEDOT:PSS reached an average concentration of 495 μmol L−1 of methanol formation during 6 repetitions after 60 min of the experiment using the same electrode. It can also be observed that the material in these conditions continues to maintain its photoelectrocatalytic activity.

Rapid hole transfer to the polymer where adsorbed water is oxidized decreases the Cu2O photocorrosion [11, 54] and leads to electron accumulation in the composite Cu2O/PEDOT:PSS, as shown in Scheme 1. It is way the polymer PEDOT:PSS that acts as coat of Cu2O plays an important role in protecting the stability of the Cu2O but also improving the CO2 photoelectrocatalytic conversion.

Conclusion

The polymer PEDOT:PSS has been used successfully as a protective layer for the semiconductor FTO/Cu2O electrode and tested in the photoelectrocatalytic reduction of CO2 to methanol (predominant product) as a way to improve its performance against photocorrosion under UV-Vis irradiation. The system was optimized, and maximum conversion of CO2/methanol was obtained for thin films of Cu2O and also thinner coating of PEDOT:PSS. The arrangement allows reaching 0.495 μmol L−1 of methanol formation after 6 repetitions during 60 min of photoelectrolysis conducted at saturated CO2 solution of NaHCO3/Na2CO3 at Eapp = 0.0 V vs Ag/AgCl, UV-Vis irradiation, and temperature of 10 °C. The polymer favors the performance of the electrode, since it acts in the protection against photocorrosion of Cu2O. In general, our results show that a simple coating of a very explored material as Cu2O and a well-know material as PEDOT:PSS can both protect and improve the system performance and show good results in the obtaining of methanol from the reduction of CO2.

Change history

08 February 2021

A Correction to this paper has been published: https://doi.org/10.1007/s12678-021-00642-1

References

J. C. Colmenares and Y.-J. Xu, Heterogeneous photocatalysis: from fundamentals to green applications, 1o edition (Springer-Verlag Berlin Heidelberg, 2016)

H. Xie, T. Wang, J. Liang, Q. Li, S. Sun, Cu-based nanocatalysts for electrochemical reduction of CO2. Nano Today 21, 41–54 (2018)

T.T. Guaraldo, J.F. de Brito, D. Wood, M.V.B. Zanoni, A New Si/TiO2/Pt p-n junction semiconductor to demonstrate photoelectrochemical CO2 conversion. Electrochim. Acta 185, 117–124 (2015)

J. Bugayong and G. Griffin, MRS Proc. 1542, mrss13 (2013)

K. Gao, K.R. McKinley, Use of macroalgae for marine biomass production and CO2 remediation: a review. J. Appl. Phycol. 6(1), 45–60 (1994)

D.R. Sauerbeck, Nutr. Cycl. Agroecosystems 60(1/3), 253–266 (2001)

M. S. Martin M. Halmann, Greenhouse gas carbon dioxide mitigation: science and technology: Martin M. Halmann, Meyer Steinberg: 9781566702843: Amazon.Com: Books, 1st ed. (CRC Press, 1998)

R. Kortlever, J. Shen, K.J.P. Schouten, F. Calle-Vallejo, M.T.M. Koper, Catalysts and reaction pathways for the electrochemical reduction of carbon dioxide. J. Phys. Chem. Lett. 6(20), 4073–4082 (2015)

E. Szaniawska, K. Bienkowski, I.A. Rutkowska, P.J. Kulesza, R. Solarska, Enhanced photoelectrochemical CO2-reduction system based on mixed Cu2O – nonstoichiometric TiO2 photocathode. Catal. Today 300, 145–151 (2018)

M. Flores-Flores, E. Luévano-Hipólito, L.M. Torres-Martínez, T.O. Do, CO2 adsorption and photocatalytic reduction over Mg(OH)2/CuO/Cu2O under UV-Visible light to solar fuels. Mater. Chem. Phys. 227, 90–97 (2019)

M.E. Aguirre, R. Zhou, A.J. Eugene, M.I. Guzman, M.A. Grela, Cu2O/TiO2 heterostructures for CO2 reduction through a direct Z-scheme: protecting Cu2O from photocorrosion. Appl. Catal. B Environ. 217, 485–493 (2017)

X. An, K. Li, J. Tang, Cu2O/reduced graphene oxide composites for the photocatalytic conversion of CO2. ChemSusChem 7(4), 1086–1093 (2014)

K. Zhao, Y. Liu, X. Quan, S. Chen, H. Yu, CO2 electroreduction at low overpotential on oxide-derived Cu/carbons fabricated from metal organic framework. ACS Appl. Mater. Interfaces 9(6), 5302–5311 (2017)

E. Szaniawska, I.A. Rutkowska, M. Frik, A. Wadas, E. Seta, A. Krogul-Sobczak, K. Rajeshwar, P.J. Kulesza, Reduction of carbon dioxide at copper(I) oxide photocathode activated and stabilized by over-coating with oligoaniline. Electrochim. Acta 265, 400–410 (2018)

J.F. De Brito, M.V.B. Zanoni, On the application of Ti/TiO 2 /CuO n-p junction semiconductor: a case study of electrolyte, temperature and potential influence on CO 2 reduction. Chem. Eng. J. 318, 264–271 (2017)

J.F. de Brito, A.R. Araujo, K. Rajeshwar, M.V.B. Zanoni, B. Zanoni, Photoelectrochemical reduction of CO2 on Cu/Cu2O films: product distribution and pH effects. Chem. Eng. J. 264, 302–309 (2015)

T. Kulandaivalu, S. Abdul Rashid, N. Sabli, T.L. Tan, Visible light assisted photocatalytic reduction of CO2 to ethane using CQDs/Cu2O nanocomposite photocatalyst. Diam. Relat. Mater. 91, 64–73 (2019)

B. Li, W. Niu, Y. Cheng, J. Gu, P. Ning, Q. Guan, Preparation of Cu2O modified TiO2 nanopowder and its application to the visible light photoelectrocatalytic reduction of CO2 to CH3OH. Chem. Phys. Lett. 700, 57–63 (2018)

N. Pugazhenthiran, K. Kaviyarasan, T. Sivasankar, A. Emeline, D. Bahnemann, R.V. Mangalaraja, S. Anandan, Sonochemical synthesis of porous NiTiO3 nanorods for photocatalytic degradation of ceftiofur sodium. Ultrason. Sonochem. 35(Pt A), 342–350 (2017)

A. M. Qadir and I. Y. Erdogan, Int. J. Hydrogen energy 1 (2019)

M. Iqbal, Y. Wang, H. Hu, M. He, A. Hassan Shah, L. Lin, P. Li, K. Shao, A. Reda Woldu, T. He, Cu2O-tipped ZnO nanorods with enhanced photoelectrochemical performance for CO2 photoreduction. Appl. Surf. Sci. 443, 209–216 (2018)

J. Ke, C. Zhao, H. Zhou, X. Duan, S. Wang, Enhanced solar light driven activity of p-n heterojunction for water oxidation induced by deposition of Cu2O on Bi2O3 microplates. Sustain. Mater. Technol. 19, e00088 (2019)

Y. Luo, Q. Huang, B. Li, L. Dong, M. Fan, F. Zhang, and Guangxi, Appl. Surf. Sci. J. 357, 1072 (2015)

Q. Hu, F. Wang, Z. Fang, X. Liu, Cu2O–Au nanocomposites for enzyme-free glucose sensing with enhanced performances. Colloids Surfaces B Biointerfaces 95, 279–283 (2012)

J.W. Hou, X.C. Yang, M.M. Cui, M. Huang, Q.Y. Wang, Synthesis and optical property of one-dimensional Ag–Cu2O heterojunctions. Mater. Lett. 74, 159–162 (2012)

D. Zhang, B. Hu, D. Guan, Z. Luo, Essential roles of defects in pure graphene/Cu2O photocatalyst. Catal. Commun. 76, 7–12 (2016)

K. B. and P. J. K. Ewelina Seta , Weronika A. Lotowska , Iwona A. Rutkowska , Anna Wadas , Adrianna Raczkowska , Marta Nieckarz, Aust. J. Chem. 69, 411 (2016)

A.N. Grace, S.Y. Choi, M. Vinoba, M. Bhagiyalakshmi, D.H. Chu, Y. Yoon, S.C. Nam, S.K. Jeong, Electrochemical reduction of carbon dioxide at low overpotential on a polyaniline/Cu2O nanocomposite based electrode. Appl. Energy 120, 85–94 (2014)

C. Janáky, K. Rajeshwar, The role of (photo)electrochemistry in the rational design of hybrid conducting polymer/semiconductor assemblies: from fundamental concepts to practical applications. Prog. Polym. Sci. 43, 96–135 (2015)

W. Dai, H. Xu, J. Yu, X. Hu, X. Luo, X. Tu, L. Yang, Photocatalytic reduction of CO 2 into methanol and ethanol over conducting polymers modified Bi 2 WO 6 microspheres under visible light. Appl. Surf. Sci. 356, 173–180 (2015)

S. Zhang, Q. Chen, Y. Wang, L. Guo, Synthesis and photoactivity of CdS photocatalysts modified by polypyrrole. Int. J. Hydrog. Energy 37(17), 13030–13036 (2012)

B.L. Groenendaal, F. Jonas, D. Freitag, H. Pielartzik, J.R. Reynolds, Poly(3,4-ethylenedioxythiophene) and its derivatives: past, present, and future. Adv. Mater. 12(7), 481–494 (2000)

S.H. Kim, J.H. Kim, H.J. Choi, J. Park, Pickering emulsion polymerized poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate)/polystyrene composite particles and their electric stimuli-response. RSC Adv. 5(88), 72387–72393 (2015)

K. Trzciński, M. Szkoda, K. Siuzdak, M. Sawczak, A. Lisowska-Oleksiak, Enhanced photoelectrochemical performance of inorganic–organic hybrid consisting of BiVO4 and PEDOT:PSS. Appl. Surf. Sci. 388, 753–761 (2016)

D. Mardiansyah, T. Badloe, K. Triyana, M.Q. Mehmood, N. Raeis-Hosseini, Y. Lee, H. Sabarman, K. Kim, J. Rho, Sci. Rep. 8, 1 (2018)

Q. Sun, S. Zhou, X. Shi, X. Wang, L. Gao, Z. Li, Y. Hao, Efficiency enhancement of perovskite solar cells via electrospun CuO nanowires as buffer layers. ACS Appl. Mater. Interfaces 10(13), 11289–11296 (2018)

J.C. Cardoso, C.A. Grimes, X. Feng, X. Zhang, S. Komarneni, M.V.B. Zanoni, N. Bao, Fabrication of coaxial TiO2/Sb2S3 nanowire hybrids for efficient nanostructured organic–inorganic thin film photovoltaics. Chem. Commun. 48(22), 2818 (2012)

J.Y. Hong, S. Huh, Hollow S-doped carbon spheres from spherical CT/PEDOT composite particles and their CO2 sorption properties. J. Colloid Interface Sci. 436, 77–82 (2014)

S. Stülp, J.C. Cardoso, J.F. de Brito, J.B.S. Flor, R.C.G. Frem, F.A. Sayão, M.V.B. Zanoni, An artificial photosynthesis system based on Ti/TiO2 coated with Cu(II) aspirinate complex for CO2 reduction to methanol. Electrocatalysis 8(3), 279–287 (2017)

J.C. Cardoso, S. Stulp, J.F. de Brito, J.B.S. Flor, R.C.G. Frem, M.V.B. Zanoni, MOFs based on ZIF-8 deposited on TiO2 nanotubes increase the surface adsorption of CO2 and its photoelectrocatalytic reduction to alcohols in aqueous media. Appl. Catal. B Environ. 225, 563–573 (2018)

G. Herzberg, Molecular spectra and molecular structure. Vol.2: Infrared and Raman Spectra of Polyatomic Molecules, 18th ed. (Krieger Pub Co, PRINCETON, 1945)

A. Lamberti, M. Destro, S. Bianco, M. Quaglio, A. Chiodoni, C.F. Pirri, C. Gerbaldi, Facile fabrication of cuprous oxide nanocomposite anode films for flexible Li-ion batteries via thermal oxidation. Electrochim. Acta 86, 323–329 (2012)

W. C. J. Ho, Q. Tay, H. Qi, Z. Huang, J. Li, and Z. Chen, Molecules 22, (2017)

V. V. Kislyuk, M. I. Fedorchenko, P. S. Smertenko, O. P. Dimitriev, and A. A. Pud, J. Phys. D. Appl. Phys. 43, 1 (210AD)

H. Hashiba, S. Yotsuhashi, M. Deguchi, and Y. Yamada, ACS Comb. Sci. acscombsci.6b00021 (2016)

D. Sebastián, A. Palella, V. Baglio, L. Spadaro, S. Siracusano, P. Negro, F. Niccoli, A.S. Aricò, CO 2 reduction to alcohols in a polymer electrolyte membrane co-electrolysis cell operating at low potentials. Electrochim. Acta 241, 28–40 (2017)

S. Stulp, J.C. Cardoso, J.F. de Brito, J.B.S. Flor, R.C.G. Frem, F.A. Sayão, M.V.B. Zanoni, An artificial photosynthesis system based on Ti/TiO2 coated with Cu(II) aspirinate complex for CO2 reduction to methanol. Electrocatalysis 8(3), 279–287 (2017)

J.C. Cardoso, S. Stulp, J.F. de Brito, J.B.S. Flor, R.C.G. Frem, M.V.B. Zanoni, MOFs based on ZIF-8 deposited on TiO2 nanotubes increase the surface adsorption of CO2 and its photoelectrocatalytic reduction to alcohols in aqueous media. Appl. Catal. B Environ. 225, 563–573 (2018)

M. Naoki Yoshihara, Arita, and M. Noda. Chem. Lett. 46, 125 (2017)

J.F. de Brito, F.F. Hudari, M.V.B. Zanoni, Photoelectrocatalytic performance of nanostructured p-n junction NtTiO2/NsCuO electrode in the selective conversion of CO2 to methanol at low bias potentials. J. CO2 Util. 24, 81–88 (2018)

G.G. Bessegato, T.T. Guaraldo, J.F. de Brito, M.F. Brugnera, M.V.B. Zanoni, Achievements and trends in photoelectrocatalysis: from environmental to energy applications. Electrocatalysis 6(5), 415–441 (2015)

J. Albo, A. Sáez, J. Solla-Gullón, V. Montiel, A. Irabien, Appl. Catal. B Environ. 176–177, 709 (2015)

J. Albo, A. Irabien, Cu2O-loaded gas diffusion electrodes for the continuous electrochemical reduction of CO2 to methanol. J. Catal. 343, 232–239 (2016)

Y. Yang, D. Xu, Q. Wu, P. Diao, Sci. Rep. 6, 1 (2016)

Funding

The authors are grateful for the financial support provided by the Ministerio de Educación (MINEDU) of Peru through of the agreement 401-2017-MINEDU of Perú, the Brazilian funding agencies FAPESP (#2015/18109-4, #2017/12790-7, and #2014/50945-1 INCT-DATREM), CNPq (#409792/2018-7), and CAPES. We are also indebted to GFQM-IQ for the X-ray diffraction measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de la Cruz, P.T.S., Irikura, K., Lachgar, A. et al. Preparation of FTO/CU2O Electrode Protected by PEDOT:PSS and Its Better Performance in the Photoelectrocatalytic Reduction of CO2 to Methanol. Electrocatalysis 11, 546–554 (2020). https://doi.org/10.1007/s12678-020-00612-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12678-020-00612-z