Abstract

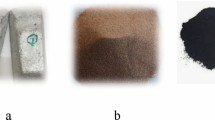

In this study, samples were produced via the Hot Isostatic pressing method by adding the elements Ni and Co at different rates into Cu–Sn (85/15) alloys. Due to their physical, thermal, and wear properties, Cu–Sn bronze alloys are widely used in journal bearings and bushings in automotive applications. In order to improve the mechanical properties of Cu–Sn alloys, it was aimed to increase their hardness and wear resistances by adding the elements Ni and Co at certain rates. By taking SEM images of the produced samples, their microstructures were examined, the hardness measurements were carried out using Brinell hardness measurement method and the porosity rates were determined based on Archimedes’ principle by conducting density measurements. Additionally, the effects of Ni and Co elements added to improve the wear properties of these alloys on wear were investigated.

taken from A2 and B2 samples after wear

Similar content being viewed by others

References

Dadbakhsh S, and Hao L, J Mater Process Technol 212 (2012) 2474.

Ceschini L, Morri A, and Sambogna G, J Mater Process Technol 204 (2008) 231.

Kashani S M M, Rhodin H, and Boutorabi S M A, Downloaded from Ijoce.Iust.Ac.Ir at 1:19 IRDT on Monday (2020).

Q T S İ P (HIP) H A Ş, (n.d.).

Aybarç U, Kara A, Çubuklusu H E, and Çe Ö B, Gazi Univ Fac Eng Arch J 32 (2017) 1327.

Ünlü B S, Sinan Köksal N, and Atik E, DEÜ Fac Eng Sci Eng Mag 5 (2003) 103.

General E, Diamond Products for Sawing and Drilling Applications (GE Superabrasives, 1991).

Mujica Roncery L, Lopez-Galilea I, Ruttert B, Huth S, and Theisen W, Mater Des 97 (2016) 544.

Islam A, and Farhat Z N, Wear 271 (2011) 1594.

Mallıkarjuna H M, Kashyap K T, Koppad P G, Ramesh C S, and Keshavamurthy R, Trans Nonferrous Met Soc China (English Ed. 26, 1755) (2016).

Ram Kumar S, Gowtham S, and Radhika N, Mater Today Proc 5 (2018) 12757.

Çelik H, and Kaplan M, Wear 257 (2004) 606.

Gür A K, Yıldız T, and Bozkurt N, DÜMF Mühendislik Derg 10 (2019) 981.

Yildiz T, Kati N, and Gür A K, J Alloys Compd 737 (2018) 8.

Yildiz T, and Aba S, J Superhard Mater 41 (2019) 157.

Ayyıldız C, Investigation of the Welding Zone in the Joining of Iron (Fe) Based Powder Metal (TM) Parts by Different Welding Methods, Master Thesis, Yıldız Technical University (2008).

Topaloğlu F, Characterızatıon of Dıamond Cutting Tools Usıng Cobalt Base Alloys as the Bındıng Matrıces, Master Thesis, Istanbul Technıcal Unıversıty (2013).

Demirel M, Investıgatıon of Influences to Wear Behaviour of Ni3Al Intermetallıc Reınforced Metal Matrıx Composıtes Produced by Powder Metallurgy, Master Thesis, Fırat Unıversıty (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yıldız, T., Katı, N. & Yılmaz, A. The Effect of the Elements Co and Ni on Wear Behaviour of Bronze Alloys Produced by the Hot Pressing Method. Trans Indian Inst Met 74, 881–889 (2021). https://doi.org/10.1007/s12666-021-02206-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-021-02206-9