Abstract

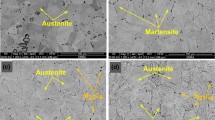

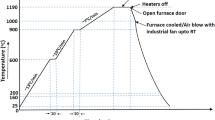

AISI 1015 low-carbon steel is being frequently applied in various steel industries, especially in the processing of parts by cold-forged, cold-headed and/or cold-formed machine tool parts. In this paper, the uniaxial compression test was conducted on AISI 1015 steel by varying the amount of percentage of cold work (PCW) and the strain rates (SRs). The PCW was varied from 15 to 65%, whereas the SR was increased from 1 × 10−4 to 1 × 10−1 s−1 with a step of 1000 times. The microstructural analyses of as-received and cold-deformed samples were carried out using various electron microscopes. The as-received microstructure revealed the presence of coarse α-ferrite and fine pearlite grains. Based on the process parameters, a cold workability map was developed and investigated by which the safe cold work parameters could be selected. The cold-deformed results through electron backscattered diffraction were explained. More elongated deformed grains (a fibre texture) were observed at low SR. A highly stressed equiaxed grain (spread texture) was obtained at a very high SR due to strain incompatibility. Finally, the work hardening behaviour was investigated as a function of SR for 65% cold-worked samples.

Similar content being viewed by others

Data Availability Statement

The experimental datasets obtained from this research work and then the analysed results during the current study are available from the corresponding author on reasonable request.

References

Bénard A E B, Hernández D M, Reyes J G G, Prado A O, and Franssens R S, Metall Mater Trans A45 (2014) 555.

Rao A V, Kumar R K, and Ramakrishnan N, Mech Adv Mater Struct14 (2007) 213.

Nabiran N, Weber S, and Theisen W, Steel Res Int83 (2012) 758.

Heibel S, Nester W, Clausmeyer T, and Tekkaya A E, in Mater Sci Eng Conf Ser (2016), p 12013.

C Medrea, and Negrea G, Int J Mater Form1 (2008) 73.

Ryl J, Arutunow A, Tobiszewski M T, and Wysocka J, Anti-Corros Methods Mater61 (2014) 328.

Sivasankaran S, Alaboodi A S, and Al-Mufadi F, Mater Manuf Process33 (2018) 1693.

Kim H, Suh D-W, and Kim N J, Sci Technol Adv Mater14 (2013) 14205.

Dennis R V, Viyannalage L T, Aldinger J P, Rout T K, and Banerjee S, Ind Eng Chem Res53 (2014) 18873.

Gunasekaran K, Lakshmi T S, and Satyanarayanan K S, Eur J Environ Civ Eng23 (2019) 368.

Peng M, Shi J, B Cui, Sun T, Li X, and Wang M, Steel Res Int88 (2017) 1700069.

Santos C A, Corrêa E C S, Aguilar M T P, Andrade M S, and Cetlin P R, J Eng Mater Technol132 (2010) 11011.

Pater Z, and Gontarz A, Materials (Basel)12 (2019) 1011.

Choi E, Kim D J, Hwang J-H, and Kim W J, Smart Mater Struct25 (2016) 85041.

Medrea-Bichtas C, Chicinaş I, and Domşa Ş, Zeitschrift Für Met93 (2002) 554.

Dargusch M S, Dehghan-Manshadi A, Shahbazi M, Venezuela J, Tran X, Song J, Liu N, Xu C, Ye Q, and Wen C, ACS Biomater Sci Eng5 (2019) 1686.

Rai P K, Shekhar S, and Mondal K, Wear412 (2018) 1.

Kim J G, Um H Y, Kang J Y, Jeong H J, Choi K H, Lee S-H, Kim S-Y, Chung J-S, and Kim H S, Mater Sci Eng A734 (2018) 408.

Sekban D M, Akterer S M, Saray O, Ma Z Y, and Purcek G, J Mater Sci Technol34 (2018) 237.

Zhang L, Ma A, Jiang J, and Jie X, Mater Des65 (2015) 115.

Huang S, Wang J, and Zhou C, Mater Sci Eng A636 (2015) 430.

Zhou C, Biner S, and LeSar R, Scr Mater63 (2010) 1096.

Shehadeh M A, Lu G, Banerjee S, Kioussis N, and Ghoniem N, Philos Mag87 (2007) 1513.

Acknowledgements

The authors acknowledge and thank Qassim University, Saudi Arabia, for all support required to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sivasankaran, S., Al-Mufadi, F. Influence of Strain Rate and Percentage of Cold Work on Room-Temperature Deformation Behaviour of AISI 1015 Carbon Steel: Detailed Microstructures and Cold Workability Map Investigations. Trans Indian Inst Met 73, 1439–1448 (2020). https://doi.org/10.1007/s12666-020-01901-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-020-01901-3