Abstract

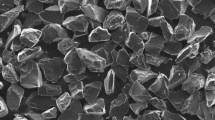

This work focuses on the investigations of hybrid reinforcement of SiC/Al2O3 as dual particle size and triple particle size (TPS) on the surface hardness of hybrid aluminum matrix composite (AMC) prepared with synergistic combination of fused deposition modeling, vacuum molding (V) process and stir casting. It was observed that TPS-based SiC resulted into highest microhardness of 45HV. Further, ANOVA revealed that the percentage contribution of particle size and type of reinforcement on surface hardness of AMC were 27.30% and 48.72%, respectively. The best parametric setting (of input parameters) for microhardness is: particle size—TPS, type of reinforcement—SiC, vacuum pressure—350 mm of Hg, sand grain size—70 (AFS no.), vibration time—4 s. and composition/proportion of reinforcement in Al matrix—10%, respectively, and overall, 5.1% improvement in microhardness was observed at proposed parametric setting. The presence of Al2O3/SiC responsible for the improvement in microhardness was supported by photomicrographs.

Similar content being viewed by others

References

Iqbal A A, and Dewan M N, Int J Appl Eng Res 11 (2016) 10408.

Sirahbizu Yigezu B, Mahapatra M M, and Jha P K, J Miner Mater Charact Eng 1 (2013) 124.

Matsunaga T, Kim J K, Hard Castle S, and Rohatgi P K, Trans AFS 104 (1996) 1097.

Hayrettin Ai, Tolga K, Ercan C, and Huseyin Ç, Tribol Int 39 (2006) 213.

Rajmohan T, Palanikumar K, and Ranganathan S, Trans Nonferrous Met Soc China 23 (2013) 2509.

Devaraju A, Kumar A, and Kotiveerachari B, Mater Des 45 (2013) 576.

Ramnath B V, Elanchezhian C, Jaivignesh M, Rajesh S, Parswajinan C, and Ghias A S A, Mater Des 58 (2014) 332.

Suresha S, and Sridhara B K, Compos Sci Technol 70 (2010) 1652.

Uvaraja V C, and Natrajan N, J Miner Mater Charact Eng 11 (2012) 757.

Prasad D S, Shoba C, and Ramanaiah N, J Mater Res Technol 3 (2014) 79.

Pugalenthi P, Jayaraman M, and Natarajan A, Appl Mech Mater 766 (2015) 246.

Radhika N, Balaji T V, and Palaniappan S, J Eng Sci Technol 10 (2015) 134.

Hashim J, Looney L, and Hashmi M S J, J Mater Proc Technol 92 (1999) 1.

Kubo Y, Nakata K, Akita K K, and Gouwens P R, AFS Trans 81 (1973) 529.

Liu Z, Hu J, Wang Q, Ding W, Zhu Y, Lu Y, and Chen W, J Mater Proc Technol 120 (2002) 94.

Kumar P, and Gaindhar J L, Trans Am Foundrym Soc 104 (1997) 635.

Singh R, Singh J, and Singh J, J Inst Eng (India) Ser C 93 (2012) 325.

Singh R, J Inst Eng India Ser C 94 (2013) 93.

Boparai K S, and Singh R, Appl Mech Mater 330 (2013) 91.

Singh R, and Singh G, J Manuf Process 19 (2015) 142.

Singh R, Podder D, and Singh S, Trans Indian Inst Metals 68 (2015) 791.

Sun Q, and Rizvi G M, Rapid Prototyp J 14 (2008) 72.

Hashim L, Looney L, and Hashmi M S J, J Mater Process Technol 92 (1999) 1.

Kumar G B V, Rao C S P, and Selvaraj N, J. Miner Mater Charac Eng 10 (2011) 59.

Sinha A, and Farhat Z, Mater Sci Appl 6 (2015) 549.

Islam M A, and Farhat Z N, Tribol Int 44 (2011) 498.

Kok M, J Mater Process Technol 161 (2005) 381.

Rahimian M, Parvin N, and Ehsani N, Mater Sci Eng A 527 (2010) 1031.

Acknowledgements

The authors are thankful to I. K.G. Punjab Technical University, Kapurthla (Pb.), India, and Guru Nanak Dev Engineering College, Ludhiana (Pb.), India, for providing this opportunity and support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Singh, S., Singh, R. & Gill, S.S. Investigations for Surface Hardness of Aluminum Matrix Composites with Hybrid Reinforcement. Trans Indian Inst Met 72, 181–190 (2019). https://doi.org/10.1007/s12666-018-1472-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1472-z