Abstract

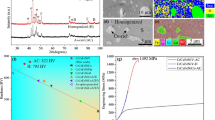

This paper presents the results of an experimental study to investigate the structural and microchemical characteristics of an equiatomic CrFeNbNiV alloy. XRD analysis of CrFeNbNiV alloy, revealed a predominant NbCrNi type HCP Laves phase conjoined with two minor tetragonal and BCC phases. Detailed microstructural investigations using electron microscopy techniques also substantiated the presence of the above mentioned phases. The structure of Laves phase in this alloy is determined ab initio for the first time using Precession Electron Diffraction technique which was in agreement with the Rietveld analysis of XRD pattern. The formation of intermetallic Laves phase was understood based on theoretical phase stability and average d- orbital energy level \(\overline{\text{Md}}\) value calculations. The alloy in the ‘as cast’ condition exhibited a very high value of hardness (~ 1500 Hv). No change in the microstructure and hardness was observed on annealing at high temperatures even up to 1373 K (1100 °C).

Similar content being viewed by others

References

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, and Chang S Y, Adv Eng Mater 6 (2004) 299.

Murty B S, Yeh J-W, and Ranganathan S, High-entropy Alloys, Butterworth-Heinemann, Oxford (2014).

Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, and Lu Z P, Prog Mater Sci, 61 (2014) 1.

Tsai M-H, and Yeh J-W, Mater Res Lett 2 (2014) 107.

Yeh J-W, Jom 65 (2013) 1759.

Huang Y-S, Recent Patents Mater Sci 2 (2009) 154.

Cantor B, Chang I, Knight P, and Vincent A, Mater Sci Eng A A 375 (2004) 213.

Lin C-M, Tsai H-L, and Bor H-Y, Intermetallics 18 (2010) 1244.

Ng C, Guo S, Luan J, Shi S, and Liu CT, Intermetallics 31 (2012) 165.

Ke G-Y, Chen S-K, Hsu T, and Yeh J-W, Annales de chimie Lavoisier 31 (2006) 669.

Guo S, Ng C, and Liu CT, J Alloy Compd 557 (2013) 77.

Zhou Y, Zhang Y, Wang F, Wang Y, and Chen G, J Alloy Compd 466 (2008) 201.

Zhou Y, Zhang Y, Wang Y, and Chen G, Mater Sci Eng A 454 (2007) 260.

Zhou Y, Zhang Y, Wang F, and Chen G, Appl Phys Lett 92 (2008) 241917.

Wu Y, Cai Y, Wang T, Si J, Zhu J, Wang Y, and Hui X, Mater Lett 130 (2014) 277.

Wang Z, Guo S, and Liu C T, JOM 66 (2014) 1966.

Hsu C-Y, Juan C-C, Wang W-R, Sheu T-S, Yeh J-W, and Chen S-K, Mater Sci Eng A 528 (2011) 3581.

Juan C-C, Hsu C-Y, Tsai C-W, Wang W-R, Sheu T-S, Yeh J-W, and Chen S-K, Intermetallics 32 (2013) 401.

Jiang H, Jiang L, Han K, Lu Y, Wang T, Cao Z, and Li T, J Mater Eng Perform 24 (2015) 4594.

Tsai M-H, Yuan H, Cheng G, Xu W, Jian W W, Chuang M-H, Juan C-C, Yeh A-C, Lin S-J, and Zhu Y, Intermetallics 33 (2013) 81.

Tsai C-W, Chen Y-L, Tsai M-H, Yeh J-W, Shun T-T, and Chen S-K J Alloy Compd 486 (2009) 427.

Tsai M-H, Yuan H, Cheng G, Xu W, Tsai K-Y, Tsai C-W, Jian W W, Juan C-C, Shen W-J, and Chuang M-H, Intermetallics 32 (2013) 329.

Xu X, Liu P, Guo S, Hirata A, Fujita T, Nieh T, Liu C, and Chen M, Acta Mater 84 (2015) 145.

Furtek A, in Book of Abstracts and Proc. 7th Int. Conf. Nuclear Option in Countries with Small and Medium Electricity Grids, (eds) Cavlina N, Pevec D, Bajs T, Croatian Nuclear Society, Croatia (2008) 19.

Murty K, and Charit I, J Nucl Mater 383 (2008) 189.

Yvon P, and Carré F, J Nucl Mater 385 (2009) 217.

Yvon P, Structural Materials for Generation IV Nuclear Reactors, Woodhead Publishing, Cambridge, 2016.

Avilov A, Kuligin K, Nicolopoulos S, Nickolskiy M, Boulahya K, Portillo J, Lepeshov G, Sobolev B, Collette JP, Martin N, and Robins AC, Ultramicroscopy 107 (2007) 431.

Kolb U, Gorelik T, Kübel C, Otten M, and Hubert D, Ultramicroscopy 107 (2007) 507.

Kolb U, Gorelik T, and Otten M, Ultramicroscopy 108 (2008) 763.

Sheng G, and Liu CT, Prog Nat Sci Mater Int 21 (2011) 433.

Yang X, and Zhang Y, Mater Chem Phys 132 (2012) 233.

Zhang Y, Zhou Y J, Lin J P, Chen G L, and Liaw P K, Adv Eng Mater 10 (2008) 534.

Mohanty S, Maity T, Mukhopadhyay S, Sarkar S, Gurao N, Bhowmick S, and Biswas K, Mater Sci Eng A 679 (2017) 299.

Mridha S, Samal S, Khan P Y, and Biswas K, Metallurg Mater Trans A 44 (2013) 4532.

Mohanty S, Gurao N, and Biswas K, Mater Sci Eng A 617 (2014) 211.

Sonkusare R, Divya Janani P, Gurao N, Sarkar S, Sen S, and Pradeep K, Mater Chem Phys 210 (2017) 269.

Takeuchi A, and Inoue A, Mater Trans 46 (2005) 2817.

Mehrer H (ed), Landolt-Börnstein numerical data and functional relationships in science and technology, Springer-Verlag, Berlin, Heidelberg, Group III, 26 (1990) p 47.

Morinaga M, Yukawa N, Adachi H, and Ezaki H, Superalloys 1984 (1984) 523.

Lu Y, Dong Y, Jiang L, Wang T, Li T, Zhang Y Entropy 17 (2015) 2355.

Zhang Y, Yang X, and Liaw P, Jom 64 (2012) 830.

He F, Wang Z, Cheng P, Wang Q, Li J, Dang Y, Wang J, and Liu C, J Alloys Compd 656 (2016) 284.

Jiang L, Lu Y, Wu W, Cao Z, and Li T, J Mater Sci Technol 32 (2016) 245.

Acknowledgements

Authors would like to thank Dr. G. Amarendra, Director, Metallurgy and Materials Group, and Dr. A. K. Bhaduri, Director, Indira Gandhi Centre for Atomic Research for their sustained support and encouragement in the pursuit of this work. Mr. Saikumaran expresses his deep sense of gratitude to HBNI for funding this project. The authors also thank UGC-DAE consortium for SEM facilities, Dr. N. V. Chandrasekar and Mr. Meenakshi sundaram for their help in alloy melting, Dr. S. Kalavathy and Mr. Irshad. K. Abbas for the XRD experiments.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Rights and permissions

About this article

Cite this article

Saikumaran, A., Mythili, R., Saroja, S. et al. Microstructural Characterization of Equiatomic CrFeNbNiV Alloy. Trans Indian Inst Met 72, 111–121 (2019). https://doi.org/10.1007/s12666-018-1466-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1466-x