Abstract

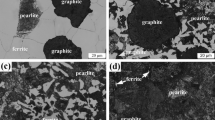

Compacted graphite cast irons are rapidly developing for they have better mechanical properties than lamellar graphite cast irons and present less porosity than spheroidal graphite cast irons. For many applications, an as-cast fully pearlitic matrix would be desired which can hardly be achieved when graphite is compacted. Addition of manganese, copper and tin are thus made as these elements are known to be pearlite promoters. However, their amount should be limited so as to avoid detrimental effects amongst which are heterogeneities in the matrix properties which impede easy machining. In the present work, a compacted graphite cast iron containing 0.3 wt% Mn, 0.8 wt% Cu and 0.1 wt% Sn was cast in sand mould and in standard thermal analysis cup. The cup sample showed a nearly fully pearlitic matrix and was selected for further study. The characterization consisted of measuring and correlating the distributions of pearlite interlamellar spacings and microhardness values. An attempt was made to look for the effect of solidification microsegregation on microhardness which did not reveal any trend.

Similar content being viewed by others

References

Janowak J F, and Gundlach R B, AFS Trans 90 (1982) 847.

Vander Voort G F, and Roosz A, Metallography 17 (1984) 1.

Ridley N, Metall Trans A 15A (1984) 1019.

Ray K K, and Mondal D, Acta metal Mater 39 (1991) 2201.

Ikeda T, Ravi V A, and Snyder G J, J Mater Res 23 (2008) 2538.

González-Martínez R, de la Torre U, Lacaze J, and Sertucha J, Mater Sci Eng A 712 (2018) 794.

Svensson H, and Sjögren T, Key Eng Mater 457 (2011) 169.

Nayyar V, Svensson H, König M, Berlund A, and Nyborg L, Int J Micro Mater Prop 8 (2013) 262.

Fourkalidi V, and Dioszegi A., Mater Sci Eng A 618 (2014) 161.

König M, and Wessen M, Int J Cast Metals Res 23 (2010) 97.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Freulon, A., Sertucha, J. & Lacaze, J. Solidification and Room Temperature Microstructure of a Fully Pearlitic Compacted Graphite Cast Iron. Trans Indian Inst Met 71, 2651–2656 (2018). https://doi.org/10.1007/s12666-018-1424-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1424-7