Abstract

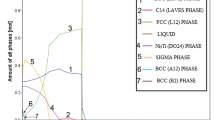

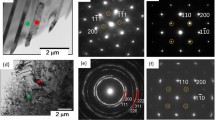

The development of single-phase high-entropy alloys (HEAs) emerges as a new paradigm shift in material research society during the last decade. A strong rise in the demand for structural and functional applications leads to the design and fabrication of super-strong eutectic HEAs through solidification processing. We report on the evolution of eutectic microstructure in CoCrFeNiNb0.5 and CoCrFeNiTa0.4 HEAs synthesized by arc melting. The evolved microstructure consists of nanolamellae of FCC γ-Ni and hexagonal β (Fe2Nb or Co2Ta type) Laves phases of 150 nm lamellae thickness. These alloys exhibit high yield strength of 2 GPa, ultimate compressive strength up to 2.2 GPa and 20% plastic strain. The strain rate jump test and transmission electron microscopic studies of deformed specimens have been performed to explore the microscopic mechanism of deformation in these high-strength advanced eutectic alloys.

Similar content being viewed by others

References

Yeh J W, Chen S K, Lin S J, Gan J Y, Chin T S, Shun T T, Tsau C H, and Chang S Y, Adv Eng Mater 6 (2004) 299.

Cantor B, Chang I T H, Knight P, and Vincent A J B, Mater Sci Eng 375 (2004) 213.

Murty B S, Yeh J W, and Ranganathan S, High entropy Alloys, Butterworth-Heinemann, Oxford (2014).

Hsu C Y, Yeh J W, Chen S K, and Shun T T, Metall Mater Trans A 35 (2004) 1465.

Sriharitha R, Murty B S, and Kottada R S, Intermetallics 32 (2013) 119.

Liu W H, He J Y, Huang H L, Wang H, Lu Z P, and Liu C T, Intermetallics 60 (2015) 1.

Agarwal R, Sonkusare R, Jha S R, Gurao N P, Biswas K and Nayan N, Mater Des 157 (2018) 539.

Wang Y P, Li B S, and Fu H Z, Adv Eng Mater 11 (2009) 641.

Ma S G, and Zhang Y, Mater Sci Eng A 532 (2012) 480.

Chen M R, Lin S J, Yeh J W, Chuang M H, Chen S K, and Huang Y S, Metall Mater Trans A 37 (2006) 1363.

Zhou Y J, Zhang Y, Wang Y L, and Chen G L, Appl Phys Lett 90 (2007) 181904.

Chen Y Y, Hong U T, Shih H C, Yeh J W, and Duval T, Corros Sci 47 (2005) 2679.

Tong C J, Chen Y L, Yeh J W, Lin S J, Chen S K, Shun T T, Tsau C H, and Chang S Y, Metall Mater Trans A 36 (2005) 881.

Biswas K, and Gurao N P, Mater Sci Eng A 657 (2016) 224.

Zhang Y, Zuo T T, Tang Z, Gao M C, Dahmen K A, Liaw P K, and Lu Z P, Prog Mater Sci 61 (2014) 1.

Huang Y S, Chen L, Lui H W, Cai M H, and Yeh J W, Mater Sci Eng A 457 (2007) 77.

Lu Y, Dong Y, Guo S, Jiang L, Kang H, Wang T, Wen B, Wang Z, Jie J, Cao Z, and Ruan H, Sci Rep 4 (2014) 1.

Jiang H, Zhang H, Huang T, Lu Y, Wang T, and Li T, Mater Des 109 (2016) 539.

Chanda B, and Das J, Adv Eng Mater 20 (2018) 1700908.

Guo S, Ng C, and Liu C T, Mater Res Lett 1 (2013) 228.

Mishra A K, Samal S, and Biswas K, Trans Indian Inst Met 65 (2012) 725.

Standard ASTM G129-00, Standard practice for slow strain rate testing to evaluate the susceptibility of metallic materials to environmentally assisted cracking, ASTM International, Conshohocken (2013).

Young R A, Introduction to Rietveld Method, Oxford University Press, Oxford, UK (1993).

Taylor G, Prog Mater Sci 36 (1992) 29.

Wei Q, Cheng S, Ramesh K T, and Ma E, Mater Sci Eng A 381(2004) 71.

Elmustafa A A, and Stone D S, J Mech Phys Solids 51 (2003) 357.

Ganji R S, Karthik P S, Rao K B S, and Rajulapati K V, Acta Mater 125 (2017) 58.

Das, J, Maity, T. and Singh, A, Trans Indian Inst Met 68 (2015) 1199.

Maity, T, Singh, A, Dutta, A and Das, J, Mater Sci Eng A 666 (2016) 72.

Juhasz A, Tasnandi P, Szaszvari P, and Kovacs I, J Mater Sci 21 (1986) 3287.

Rogal L, Morgiel J, Świątek Z, and Czerwiński F, Mater Sci Eng A 651 (2016) 590.

Senkov O N, Wilks G B, Scott J M, and Miracle D B, Intermetallics 19 (2011) 698.

Wang X F, Zhang Y, Qiao Y, and Chen G L, Intermetallics 15 (2007) 357.

Wang F J, Zhang Y, Chen G L, and Davies H A, J Eng Mater Technol 131 (2009) 034501.

Shun T T, and Du Y C, J Alloys Compd 479 (2009) 157.

Park J M, Sohn S W, Kim T E, Kim D H, Kim K B, Kim W T, Scripta Mater 57 (2007) 1153.

Maity T, and Das J, AIP Advances 2 (2012) 032175.

Maity T, and Das J, Intermetallics 63 (2015)51.

Xing L Q, Li Y, Ramesh K T, Li J, and Hufnagel T C, Phys Rev B 64 (2001) 180201.

Schroers J, and Johnson W L, Phys Rev Lett 93 (2004) 255506.

Das J, Tang M B, Kim K B, Theissmann R, Baier F, Wang W H, and Eckert J, Phys Rev Lett 94 (2005) 205501.

Acknowledgements

The authors acknowledge the technical support provided by M. Das, S. Maity and R. Kundu. The funding provided by SRIC (SGIRG) IIT Kharagpur and Naval Research Board (NRB/4003/PG/357), Government of India are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chanda, B., Verma, A. & Das, J. Nano-/Ultrafine Eutectic in CoCrFeNi(Nb/Ta) High-Entropy Alloys. Trans Indian Inst Met 71, 2717–2723 (2018). https://doi.org/10.1007/s12666-018-1408-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-018-1408-7