Abstract

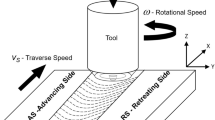

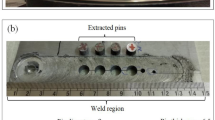

In this paper, dissimilar aluminium Al-5086/C10100 copper spot joints were made using friction stir spot welding, by varying the significant process parameters such as tool rotational speed, plunge depth and dwell time. Using a central composite design model, twenty experiments were conducted and the welded joints were subjected to corrosion analysis. Using electro-chemical system, polarization tests were conducted and salt fog testing was conducted for 20 h. Empirical relationships were established between the process parameters with the pitting potential and the rate of mass loss. ANOVA was used to evaluate the model’s significance and optimization was done using response surface methodology. It was observed that, at 1112 rpm of tool speed, 2.07 mm of plunging depth and 12.3 s of dwelling period, most positive pitting potential of − 586.86 eV and minimum mass loss of 0.0010234 g occurred. The model was validated with error within three percentage, which indicated high predictability of the developed model.

Similar content being viewed by others

References

Thomas W M, Nicholas E D, Needham J C, Murch M G, Temple Smith P, and Dawas C J, Friction Stir Welding. International Patent Application No. PCT/GB92/02203 G (1991).

Badarinarayan H, Fundamentals of Friction Stir Spot Welding, Ph D Thesis, Missouri University (2009).

Manickam S, and Balasubramanian V, J Manuf Eng 10 (2015) 207.

Arul S G, Pan T, Lin P C, Pan J, Feng Z, and Santella M L, Proceeding of 2005 SAE World Congress, Detroit, MI (2005).

Pan T Y, Joaquin A, Wilkosz D E, Reatheford L, Nicholson J M, Feng Z, and Santella M L, 5th International Symposium on Friction Stir Welding, TWI, Metz (2004).

Fahimpour V, Sadrnezhaad S K, and Karimzadeh F, Mater Des 39 (2012) 329.

Weifeng X, Jnhe L, and Hongqiang Z, Electrochim Acta, 55 (2010) 2918.

Paglia C S, and Buchheit R G, Scr Mater 58 (2008) 383.

Yong Gui Y, Li M, Jie Z H, and Bing Z H, Corros Sci Prot Technol, 21 (2009) 119.

Chen Y, Liu C, Zhou J, and Wang X, Int J Fatigue, 98 (2017) 269.

Reyes Hernández D, Manzano Ramírez A, Encinas A, Sánchez Cabrera V M, Marroquín De Jesús A, García García R, Orozco G, and Olivares Ramírez J M, Fuel, 198 (2017) 165.

Liu W, Pan H, Li L, Lv H, Wu Z, Cao F, and Zhu J, J Manuf Process, 25 (2017) 418.

Dick P A, Knörnschild G H, and Dick L F P, Corros Sci, 114 (2017) 28.

Lakshminarayanan A K, Annamalai V E, and Elangovan K, J Mater Res Technol, 4 (2015) 262.

Montgomery D C, Design and Analysis of Experiments, John Wiley & Sons, New York (2001).

Venkata Rao C, Madhusudhan Reddy G, and Srinivasa Rao K, Def Technol, 11 (2015) 123.

Srinivasa Rao K, and Prasad Rao K, Trans Indian Inst Met, 576 (2004), 593.

Paventhan R, Lakshminarayanan P R, and Balasubramanian V, Trans Nonferrous Met Soc China 21 (2011) 1480.

Miller J E F, and Johnson R, Probability and Statistics for Engineers, 5, Prentice Hall, New Delhi (1996).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Siddharth, S., Senthilkumar, T. Optimizing Process Parameters for Increasing Corrosion Resistance of Friction Stir Spot Welded Dissimilar Al-5086/C10100 Joints. Trans Indian Inst Met 71, 1011–1024 (2018). https://doi.org/10.1007/s12666-017-1236-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1236-1