Abstract

Recent advances in the manufacture and processing of high purity NiTinol 60 (60 wt% Ni–40 wt% Ti) has spurred a renewed interest in the use of this alloy for structural and mechanical component applications. NiTinol 60 (60NiTi) exhibits excellent corrosion resistance, can be hardened to high levels, has a low elastic modulus and extensive elastic range that imparts high mechanical contact load resilience. It is dimensionally stable, has good bio-compatibility, can be machined into precision components and is non-magnetic. This unique set of characteristics make the intermetallic 60NiTi suitable for a wide variety of applications in the marine, medical, aerospace and food processing industries. This article surveys and reviews a broad range of historic and recent publications on 60NiTi to highlight what is known and areas that require further study. In particular, recent results indicate a dichotomy in friction and wear behavior. Under good lubrication (liquid or solid) both friction and wear are low but in dry un-lubricated sliding, wear exceeds that of other materials such as steel that have comparable hardness. This unexpected behavior is proposed as an important topic for future investigations before any of widespread adoption in engineering applications.

Similar content being viewed by others

References

DellaCorte C, in Proc Symp 40th Aerospace Mechanisms Symposium, Cocoa Beach, Florida (2010).

DellaCorte C, Adv Sci Technol 89 (2014) 1.

Ingole S, JOM 65 (2013) 792.

DellaCorte C, Noebe R, Stanford M, and Padula S, Presented at the Rolling Element Bearings Symposium, Anaheim, California (2011).

DellaCorte C, Pepper S, Noebe R, Hull D, and Glennon G, Intermetallic Nickel-Titanium Alloys for Oil-Lubricated Bearing Applications, Report NASA/TM-2009-215646, NASA Glenn Research Center, Cleveland (2009).

Wojcik C, US Patent 7192496 (2007).

Mosley M J, and Mavroidis C, J Dyn Syst Meas Contr 123 (2001) 103.

Buehler W J, and Wang F E, Ocean Eng 1 (1968) 105IN7109.

Julien G J, US Patent 6422010 (2002).

Neupane R, and Farhat Z, Mater Sci Appl 6 (2015) 694.

Clayton P, Wear 162–164 (1993) 202.

Qian L, Xiao X, Sun Q, and Yu T, Appl Phys Lett 84 (2004) 1076.

Liu R, and Li D I, Metall Mater Trans A 31A (2000) 2773.

Lin H C, Wu S K, and Yeh C, Wear 249 (2001) 557.

Li D Y, Wear 255 (2003) 617.

Otsuka K, and Ren X, Progr Mater Sci 50 (2005) 511.

Weafer F M, and Bruzzi M S, Int J Fatigue 93 (2016) 148.

Hornbuckle B C, Xiao X Y, Noebe R D, Martens R, Weaver M L, and Thompson G B, Mater Sci Eng A 639 (2015) 336.

DellaCorte C, Moore III L E, and Clifton J S, The Effect of Pre-stressing on the Static Indentation Load Capacity of the Superelastic 60NiTi, Report NASA/TM-2013-216479, NASA Glenn Research Center, Cleveland (2013).

Stanford M K, Thomas F, and DellaCorte C, Processing Issues for Preliminary Melts of the Intermetallic Compound 60-NiTiNOL, Report NASA/TM-2012-216044, NASA Glenn Research Center, Cleveland (2012).

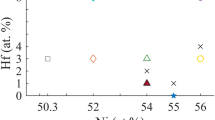

Stanford M K, Hardness and Microstructure of Binary and Ternary Nitinol Compounds, Report NASA/TM-2016-218946, NASA Glenn Research Center, Cleveland (2016).

Hornbuckle B C, Investigation in Phase Stability and Mechanical Attributes in Nickel-Rich Nitinol with and Without Hafnium Additions, Ph D Thesis, The University of Alabama: Alabama, United States (2014).

Kim J, and Miyazaki S, Acta Mater 53 (2005) 4545.

Stanford M, Wozniak W A, and McCue T, Addressing Machining Issues for the Intermetallic Compound 60-NITINOL, Report NASA/TM-2012-216027, NASA Glenn Research Center, Cleveland (2012).

DellaCorte C, and Wozniak W A, Design and Manufacturing Considerations for Shockproof and Corrosion-Immune Superelastic Nickel-Titanium Bearings for a Space Station Application, Report NASA/TM-2012-216015, NASA Glenn Research Center, Cleveland (2012).

Stanford M, Preliminary Investigation of Surface Treatments to Enhance the Wear Resistance of 60-NiTinol, Report NASA-2016-219121, NASA Glenn Research Center, Cleveland (2016).

DellaCorte C, The Effect of Indenter Ball Radius on the Static Load Capacity of the Superelasic 60NiTi for Rolling Element Bearings, Report NASA/TM-2014-216627, NASA Glenn Research Center, Cleveland (2014).

Stanford M K, Thermophysical Properties of 60-NITINOL for Mechanical Component Applications, Report NASA/TM-2012-216056, NASA Glenn Research Center, Cleveland (2012).

DellaCorte C, Moore III L E, and Clifton J S, Static Indentation Load Capacity of the Superelastic 60NiTi for Rolling Element Bearings, Report NASA/TM-2012-216016, NASA Glenn Research Center, Cleveland (2012).

Julien G J, US Patent #6886986 (2005).

Dehghani K, and Khamei A, Mater Sci Eng A 527 (2010) 684.

Stanford M K, Hot Isostatic Pressing of 60-Nitinol, Report NASA/TM-2015-218884, NASA Glenn Research Center, Cleveland (2015).

Stanford M K, Charpy Impact Energy and Microindentation Hardness of 60-NITINOL, Report NASA/TM-2012-216029, NASA Glenn Research Center, Cleveland (2012).

DellaCorte C, Stanford M K, and Jett T R, Tribol Lett 57 (2015) 26.

DellaCorte C, and Glennon G, US Patent 8182741 (2012).

DellaCorte C, Howard A, Thomas F, and Stanford M, Microstructural and Material Quality Effects on Rolling Contact Fatigue of Highly Elastic Intermetallic NiTi Ball Bearings, Report NASA/TM-2017-219466, NASA Glenn Research Center, Cleveland (2017).

Adharapurapu R R, Jiang F, and Vecchio K S, Mater Sci Eng A 527 (2010) 1665.

Benafan O, Garg A, Noebe R D, Skorpenske H D, An K, and Schell N, Intermetallics 82 (2017) 40.

Hornbuckle B C, Noebe R D, and Thompson G B, J Alloys Compd 640 (2015) 449.

Adharapurapu R R, Phase Transformations in Nickel-Rich Nickel-Titanium Alloys: Influenece of Strain-Rate, Temperature, Thermomechanical Treatment and Nickel Composition on the Shape Memory and Superelastic Characteristics, Ph D Thesis, University of California, UC San Diego, United States (2007).

Thomas F, The Effect of Various Quenchants on the Hardness and Microstructure of 60-NITINOL, Report NASA/TM-2015-218463, NASA Glenn Research Center (2015).

Li D Y, Wear 221 (1998) 116.

Stanford M, Hardness and Second Phase Percentage of Ni-Ti-Hf Compounds After Heat Treatment at 700 °C, Report NASA/TM-2017-219453, NASA Glenn Research Center, Cleveland (2017).

Adharapurapu R, and Vecchio K, Exp Mech 47 (2007) 365.

DellaCorte C, and Moore III L E, in Proc Symp 40th Aerosspace Mechanisms, Cocoa Beach, FL, United States (2010).

Patil D, Marinack M C, DellaCorte C, and Higgs C F, TRIBOL T 60 (2016) 615.

Qin Q, Wen Y, Wang G, and Zhang L, J Mater Eng Perform 25 (2016) 5167.

Liu R, and Li D, Wear 251 (2001) 956.

Lin H, He J, Chen K, Liao H, and Lin K, Metall Mater Trans A 28 (1997) 1871.

Miyoshi K, Lukco D, and Cytron S J, Oxide Ceramic Films Grown on 55Ni-45Ti for NASA and Department of Defense Applications: Unidirectional Sliding Friction and Wear Evaluation, Report NASA/TM-2004-212979, NASA Glenn Research Center, Cleveland (2004).

Zeng Q-f, and Dong G-n, Trans Nonferrous Met Soc China 24 (2014) 354.

Nasehi J, Ghasemi H M, and Abedini M, TRIBOL T 59 (2016) 286.

DellaCorte C, Thomas F, and Leak O, Tribological Evaluation of Candidate Gear Materials Operating Under Light Loads in Highly Humid Conditions, Report NASA/TM-2015-218896, NASA Glenn Research Center, Cleveland (2015).

Pepper S V, DellaCorte C, Noebe R D, Hall D R, and Glennon G, Presented at the ESMATS 13 Conference, Vienna, Austria (2009).

Pepper S V, DellaCorte C, and Glennon G, Lubrication of Nitinol 60, Report NASA/TM-2010-216331, NASA Glenn Research Center, Cleveland (2010).

DellaCorte C, in Proceedings of the ASME/STLE 2009 International Joint Tribology Conference, Memphis, Tennessee (2009), p 293.

Zeng Q-f, Zhao X-m, Dong G-n, and Wu H-x, Trans Nonferrous Met Soc China 22 (2012) 2431.

Stott A C, Brauer J I, Garg A, Pepper S V, Abel P B, DellaCorte C, Noebe R D, Glennon G, Bylaska E, and Dixon D A, J Phys Chem C 114 (2010) 19704.

Zeng Q, Dong G, and Martin J M, Sci Rep 6 (2016) 29992.

Zeng Q, and Dong G, Tribol Lett 52 (2013) 47.

Tang W, Metall Mater Trans A 28 (1997) 537.

Kaya I, Smart Mater Struct 25 (2016).

White E V, Calkins F T, Mabe J H, and Butler G W, Proceedings of the SPIE: Smart Structures and Materials 6171 (2006) p 617100.

Tan L, Biomaterials 24 (2003) 3931.

Ryhanen J, Biocompatibility Evaluation of Nickel-Titanium Shape Memory Metal Alloy, Ph D Thesis, University of Oulu, Finland (1999).

Khanlari K, Ramezani M, Hayat M, Kelly P, Cao P, and Neitzert T, MATEC Web of Conferences 109 (2017) p 01002.

Bolelli G, Bonferroni B, Laurila J, Lusvarghi L, Milanti A, Niemi K, and Vuoristo P, Wear 276 (2012) 29.

Gialanella S, Ischia G, and Straffelini G, J Mater Sci 43 (2008) 1701.

Smialek J L, Garg A, Rogers R B, and Noebe R D, Metall Mater Trans A 43 (2012) 2325.

Firstov G, Vitchev R, Kumar H, Blanpain B, and Van Humbeeck J, Biomaterials 23 (2002) 4863.

Wu S K, Chu C L, and Lin H C, Surf Coat Technol 92 (1997) 206.

Julien G J, US Patent 6454016 (2002).

Julien G J, US Patent 6267402 (2001).

DellaCorte C, in Proc Symp 43rd Aerospace Mechanisms, (NASA/CP-2016-219090) (2016).

Bahraminasab M, and Jahan A, Mater Des 32 (2011) 4471.

Elloy M A, Wright J T M, and Cavendish M E, Acta Orthop Scand 47 (2009) 193.

Shwartsmann C, Boschi L, Boschi L, Ramiro G, and Yepez A, Rev Bras Ortop 47 (2012) 154.

Hermawa H, Ramdan D, and Djuansjah J, in Biomedical Engineering-From Theory to Applications, CHPT 17 (2011).

Matassi F, Botti A, Sirleo L, Carulli C, and Innocenti M, Clin Cases Miner Bone Metab 10(2) (2013) 111.

Ni W, Cheng Y-T, Lukitsch M, Weiner A M, Lev L C, and Grummon D S, Wear 259 (2005) 842.

Alcala J, Barone A, and Anglada M, Acta Mater 48 (2000) 3451.

Acknowledgements

The authors would like to thank Dr. Christopher DellaCorte, National Aeronautics and Space Administration (NASA), Glenn Research Center, Cleveland, Ohio for his generous technical assistance and continuous support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khanlari, K., Ramezani, M. & Kelly, P. 60NiTi: A Review of Recent Research Findings, Potential for Structural and Mechanical Applications, and Areas of Continued Investigations. Trans Indian Inst Met 71, 781–799 (2018). https://doi.org/10.1007/s12666-017-1224-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1224-5