Abstract

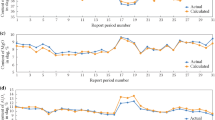

Twenty-five numbers of blast furnace slag samples are collected from different operational Indian blast furnaces. The viscosities of these slag samples are estimated using various models developed by several researchers for the purpose. Subsequently, viscosities of some selected slag samples are measured using a high temperature viscometer to choose the best possible model that can be used in the present investigation. On the basis of the results, a comparison is made between the various models bringing about the shortcomings of these mathematical models. It is observed that the estimated viscosities by Iida model are best fitted with the viscosities of slags measured by high temperature viscometer and hence, the viscosity data obtained by Iida model are analyzed at length to ascertain the compositional dependence of slag viscosity. It is observed that the industrial blast furnace slag viscosity is greatly influenced by its CaO/SiO2 ratio, MgO and Al2O3 contents.

Similar content being viewed by others

Notes

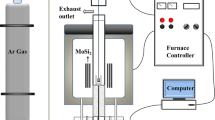

To avoid the measurement difficulties, the viscosities of some selected slag samples are measured experimentally. The selection is made based on the slag composition pertaining to C/S ratio.

References

Tiwary J N, Mishra B, Sarkar S, and Mohanty U K, Emerg Mater Res 2 (2013) 152.

Gupta S S, and Chatterjee A, Blast Furnace Iron Making, SBA Publication, Washington (1995) 20.

Behera R C, Mohanty U K, and Mohanty A K, High Temp Mater Process 9 (1990) 57.

Kondratiev A, Jak E, and Hayes P C, JOM 54 (2002) 41.

Shankar A, Gornerup M, Lahiri A K, and Seetharaman S, Metall Mater Trans B 38 (2007) 911.

Mills K C, Viscosities of Molten Slags, Slag Atlas 2nd edition, Düsseldorf, Germany, (1995) 349.

Sridhar S, JOM 54 (2002) 46.

Shu Q F, Steel Res Int 80 (2009) 107.

Mills K C, The estimation of slag properties, Short course presented as part of Southern African Pyrometallurgy 2011, 7th of March, (2011).

Mills K C, and Sridhar S, Ironmak Steelmak 26 (1999) 262.

Ray H S, and Pal S, Ironmak Steelmak 31 (2004) 125.

Iida T, Sakai H, Kita Y, and Shigeno K, ISIJ Int 40 (2000) S110.

Iida T, 5th International Conferenc on Molten Slags, Fluxes and Salts, Warrendale, PA: ISS (1997) 877.

Iida T, in Proceedings of the Mills Symposium, London (2002) 101.

Urbain G, Cambier F, Deletter M, and Anseau M R, Trans J Br Ceram Soc 80 (1981) 139.

Urbain G, Steel Res 58 (1987) 111.

Kondratiev A, and Jak E, Metall Mater Trans B 32 (2001)1015.

Kekkonen M, Oghbasilasie H, and Louhenkilpi S, Viscosity models for molten slags, Department of materials science and engineering, research report, science and technology, Aalto university publication series, 12 (2012) 6.

Duffy J A, and Ingram M D, J. Am. Chem. Soc. 93 (1971) 6448.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pati, A., Sahoo, S.K., Mishra, B. et al. Viscosity of Industrial Blast Furnace Slag in Indian Scenario. Trans Indian Inst Met 71, 801–812 (2018). https://doi.org/10.1007/s12666-017-1212-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1212-9