Abstract

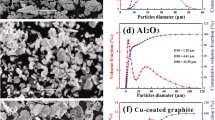

The objective of this paper is to investigate the tribological properties of a novel iron-copper-graphite (Fe–Cu–C) based self lubricating material at high temperature. The effect of Calcium fluoride (CaF2) as a solid lubricant on friction and wear behavior of sintered Fe–Cu–C materials has been studied. Fe–Cu–C based self-lubricating materials were prepared by single stage compaction and sintering process. CaF2 was added to Fe–2Cu–0.8C based materials in different weight percentages of 0, 3, 6, 9, and 12 wt%. The developed materials were tested for mechanical and tribological properties at high temperature (500 °C). The worn out surfaces were analyzed using a scanning electron microscope. The material with 3 wt% CaF2 exhibited high hardness value where as compression strength of the materials decreased with the addition of CaF2. Samples with 3, 6, and 9 wt% exhibited low value of coefficient of friction (COF) than base matrix. The material with 3 wt% CaF2 addition exhibited better wear resistance as compared to other developed materials. The worn surfaces were mostly characterized by delaminating and abrasive wear. A high temperature solid lubricant CaF2 was used in Fe–Cu–C based matrix and, the developed composites were tested for tribological properties at high temperature. The results showed that addition of CaF2 in Fe–Cu–C improved the friction and wear properties. Based upon the findings, the developed material could be used for antifriction applications.

Similar content being viewed by others

References

Ghaderi A R, Ahmadabadi M N, and Ghasemi H M, Wear 255 (2003) 410.

Liu X, Takamori S, and Osawa Y, J Mater Sci 21(2004) 6097.

Murakami T, Inoue T, Shimura H, Nakano M, and Sasaki S, Mater Sci Eng A 432 (2006) 113.

Li J L, and Xiong D S, Wear 265 (2008) 533.

Cranmer D C, Tribol Trans 31(1988) 164.

Zhao J C, and Westbrook J H, MRS Bull 28 (2003) 622.

Conte Jr A, Lubr. Eng 28 (1972) 423.

Milan J C, Carvalho M A, Xavier R R, Franco S D, and De Mello JD, Wear 259 (2005) 412.

Stott F H, Lin D S, Wood G C, and Stevenson C W, Wear 36 (1976) 147.

Taktak S, Surf. Coat. Technol. 201 (2006) 2230.

Woydt M, Skopp A, Dörfel I, and Witke K, Wear 218 (1998) 84.

Fedorchenko I M, Zozulya V D, and Shevchuk Y F, 9 (1970) 818.

Miroshnikov V N, and Shevchuk Y F, Powder Metall Met Ceram 10 (1971) 911.

Shevchuk Y F, Powder Metall Met Ceram 40 (2001) 40.

Kostornov A G, Fushchich O I, Gorban V F, Chevychelova T M, and Kostenko O D, Powder Metall Met Ceram 51 (2012) 412.

Zuomin L, and Childs T H Wear 257 (2004) 435.

Han J, Jia J, Lu J, and Wang J, Tribol Lett 34 (2009) 193.

Dhanasekaran S,and Gnanamoorthy R, Mater Des 28 (2007)1135.

Dhanasekaran S, and Gnanamoorthy R, J Mater Sci 42 (2007) 4659.

Merie V V, Cândea V C, Bîrleanu C, Păşcuţă P, and Popa C O, J Compos Mater 48 (2014).

Zhang A M, Hai H A, and Zhang X G, Trans Non Ferr Met Soc China 23(2013) 3167.

Song K H, Kim H S, and Kim W Y, Adv Mater Sci 28 (2011)158.

Oh J M, Lim J W, Lee B G, Suh CY, Cho SW, Lee S W, and Choi G S, Mater Trans 51 (2010) 2009.

Kim H W, Noh Y J, Koh Y H, Kim H E, and Kim H M, Biomater 23 (2002) 4113.

Du L, Huang C, Zhang W, Zhang J, and Liu W, J Therm Spray Technol 19 (2010) 551.

Barrau O, Boher C, Vergne C, Rezai-Aria F, and Gras R, Karlst Univ (2002) 81.

Jiang J, Stott F H, and Stack M M, Wear 176 (1994) 185.

Wang H M, Yu Y L, and Li S Q, Scr Mater 47 (2002) 57.

Shen P Z, Song M, Gao H Y, He Y H, Zou J, and Xu N P, J Mater Sci 44 (2009) 4413.

Samuels L E, Light microscopy of carbon steels, Asm International, (1999), p 371.

Marciuš M, Ristić M, Ivanda M, and Musić S, Croat Chem Acta 85 (2012) 117.

Ganechari S M, Kabadi R V, Kori S A, and Burbure R R, Thinkquest Springer India (2011) 239.

Islam M A, and Farhat Z N Tribol Int 44 (2011) 498.

Zambrano O A, Coronado J J, and Rodríguez S A, Tribol Lett 57 (2015) 1.

Kashani H, Amadeh A, Ghasemi and H M, Wear 262 (2007) 800.

Wang S Q, Wei M X, Wang F, Cui X H, and Dong C Tribol Lett 32 (2008) 67.

Gangatharan K, Selvakumar N, Narayanasamy P, and Bhavesh G, Int J Surf Sci Eng 10 (2016) 27.

Acknowledgements

The authors would like to thankfully acknowledge the staff of Department of Mechanical Engineering, Shri Mata Vaishno Devi University, Katra, J&K, India for their support in carrying out this study. We also extend our gratitude to Metallurgical Products India Pvt. Limited (Maharashtra) and Timcal Ltd. (Maharashtra) for providing Calcium Fluoride and graphite powders for carrying out this research. We acknowledge the help forwarded by CIFC- BHU, India for carrying out SEM microscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anand, A., Sharma, S.M. High Temperature Friction and Wear Characteristics of Fe–Cu–C Based Self-Lubricating Material. Trans Indian Inst Met 70, 2641–2650 (2017). https://doi.org/10.1007/s12666-017-1124-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1124-8