Abstract

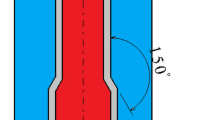

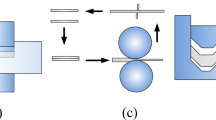

Severe plastic deformation (SPD) is divided to a number of branches. One of the most important branches of SPD of tube materials is parallel tubular channel angular pressing (PTCAP). The PTCAP process is more complicated than another SPD process for metal tubes. The PTCAP process includes two half cycles for obtaining the desired product. There are some factors, which affect the PTCAP process. For instance, deformation ratio, clamping force, channel angles, and curvature angles. In this paper, the PTCAP process for aluminum alloy (Al 5083) was simulated through the finite element ABAQUS software in order to investigate the effect of die parameters. Thus, the influences of deformation ratio, channel angles, and curvature angles on the PTCAP process were examined numerically. In addition, to verify the finite element method (FEM) results, the PTCAP process was done experimentally. To some extent, good conformity was observed between the FEM calculations and experimental results.

Similar content being viewed by others

References

Yoon S C, Horita Z, and Kim H S, J. Mater. Process. Technol. 201 (2008) 32.

Abrinia K, and Mirnia M, Int. J. Adv. Manuf. Technol. 46 (2010) 411.

Lee S, Saito Y, Tsuji N, Utsunomiya H, and Sakai T, Scr. Mater. 46 (2002) 281.

Faraji G, Mashhadi M M, and Kim H S, Mater. Lett. 65 (2011) 3009.

Faraji G, Mashhadi M, Abrinia K, and Kim H, Appl. Phys. A 107 (2012) 819.

Faraji G, Mosavi M M, and Seop K H, Mater. Trans. 53 (2012) 8.

Segal V M, Mater. Sci. Eng. A 197 (1995) 157.

Richert J, Richert M, Zasadziński J, and Korbel A, Patent PL (1979), no. 123026.

Zu-de Z, Qiang C, Yan-bin W, and Da-yu S, Trans. Nonferrous Metals Soc. China 19 (2009) 535.

Zhu Y T, Jiang H, Huang J, and Lowe T C, Metall. Mater. Trans. A 32 (2001) 1559.

Faraji G, Mashhadi M, Dizadji A, and Hamdi M, J. Mech. Sci. Technol. 26 (2012) 3463.

Faraji G, Babaei A, Mashhadi M M, and Abrinia K, Mater. Lett. 77 (2012) 82.

Faraji G, Bushroa A, Babaei A, Mashhadi M, and Hamdi M, Mater. Sci. Eng. A 563 (2013) 193.

Nagasekhar A V, Yoon S C, TickHon Y, and Kim H S, Comput. Mater. Sci. 46 (2009) 347.

Xu C, Furukawa M, Horita Z, and Langdon T G, Acta Mater. 51 (2003) 6139.

Torabzadeh H, Faraji G, and Zalnezhad E, Trans. Indian Inst. Metals 69 (2016) 1217.

Afrasiab M, Faraji G, Tavakkoli V, Mashhadi M M, and Dehghani K, Trans. Indian Inst. Metals 68 (2015) 873.

Metals Test Methods and Analytical Procedures, Annual Book of ASTM Standards, ASTM-E8 and ASTM-E517, West Conshohocken, PA Vol 03.01, 2000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Javidikia, M., Hashemi, R. Analysis and Simulation of Parallel Tubular Channel Angular Pressing of Al 5083 Tube. Trans Indian Inst Met 70, 2547–2553 (2017). https://doi.org/10.1007/s12666-017-1117-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1117-7