Abstract

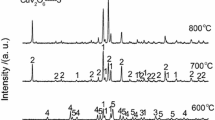

The ever increasing application of zinc titanate ceramics as a dielectric material in microwave devices and low temperature co-fired ceramics calls for the improvement in their dielectric properties. In this paper, the effect of different sintering techniques on the dielectric properties of zinc titanate have been discussed. Zinc titanate was prepared by ball milling 1:1 molar ratio of ZnO and TiO2 for 12 h and calcined at 800 °C for 2 h. The presence of ZnTiO3 and Zn2TiO4 phases were confirmed by X-ray diffraction and the dielectric properties of the sintered samples were studied using LCR meter. Samples consolidated by spark plasma sintering (SPS) showed highest densification (13% increase), higher dielectric permittivity (ɛr = 25.17) and Q factor (Q factor = 162.78) with lower loss tangent values (tanδ = 0.00614) than that of microwave sintered samples (ɛr = 21.86, Q factor = 99.08, tanδ = 0.01009) and conventionally sintered samples (ɛr = 20.54, Q factor = 60.07, tanδ = 0.01665). The fabrication time was considerably reduced for the materials prepared via SPS than that prepared by conventional route with improved properties and also the dependence of dielectric properties on density was confirmed in this research work.

Similar content being viewed by others

References

Dulin F H, and Rase D E, J Am Ceram Soc 43 (1960) 125.

Kim H T, Byun J D, and Kim Y, Mater Res Bull 33 (1998) 975.

Zhang Q L, Yang H, Zou J L, and Wang H P, Mater Lett 59 (2005) 880.

Hou L, Hou Y D, Zhu M K, Tang J, Liu J B, and Wang H, Mater Lett 59 (2005) 197.

Lee Y C, Huang Y L, Lee W H, and Shieu F S, Thin Solid Films 518 (2010) 7366.

Chang Y S, Chang Y H, Chen I G, Chen G J, Chai Y L, Fang T H, and Wu S, Ceram Int 30 (2004) 2183.

Obradovic N, Mitrovic N, and Pavlovic V, Ceram Int 35 (2009) 35.

Lokesh B, Kaleemulla S, and Madhusudhana Rao N, Int J ChemTech Res 6 (2014) 1929.

Liu X, Mater Lett 80 (2012) 69.

Zhu J, Kipkoech E R, and Lu W, J Eur Ceram Soc 26 (2006) 2027.

Lei W, Lu W Z, Zhu J H, and Wang X H, Mater Lett 61 (2007) 4066.

Li Y, Cheng T, and Lee Y, New J Glass Ceram 4 (2014) 1.

Lee Y C, Yeh Y Y, and Tsai P R, J Eur Ceram Soc 32 (2012) 1725.

Takeuchi T, Betourne E, Tabuchi M, and Kageyama H, J Mater Sci 34 (1999) 917.

Tamari N, Tanaka T, Tanaka K, Kondoh I, Kawahara M, and Tokita M, J Ceram Soc Jpn 103 (1995) 740.

Sundararajan T, and Balasivanandha Prabu S, Mater Chem Phys 139 (2013) 465.

Takeuchi T, Tabuchi M, and Kageyama H, J Am Ceram Soc 82 (1999) 939.

Licheri R, Fadda S, Orru R, Cao G, and Buscaglia V, J Eur Ceram Soc 27 (2007) 2245.

Luo J, Ma S Y, Cheng L, Song H S, and Li W Q, Mater Lett 138 (2015) 100.

Reddy K R, Nakata K, and Ochiai T, J Nanosci Nanotechnol 10 (2010) 7951.

Lines M E, and Glass A M, Principle and Application of Ferroelectrics and Related Materials, Clarendon Press, Oxford (1977).

Bobowska I, Opasinska A, Wypych A, and Wojciechowski P, Mater Chem Phys 134 (2012) 87.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhoopathy, B.G., Vishwath Ram, A., Rajeshwara Rao, R.J. et al. Enhanced Dielectric Properties in Spark Plasma Sintered Zinc Titanate Ceramics. Trans Indian Inst Met 70, 2571–2574 (2017). https://doi.org/10.1007/s12666-017-1109-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1109-7