Abstract

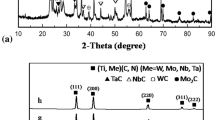

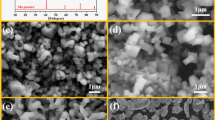

In the present research, the effect of TaC addition as ternary carbide on the microstructure and mechanical properties of dense Ti(CN)–WC–Ni/Co cermets processed via powder metallurgy route by conventional and SPS sintering technique was investigated. XRD patterns of SPS sintered cermets revealed peak broadening confirming evolution of refined carbide size during sintering. Sintered cermets showed Ti(CN) core and (Ti,W)(CN)/(Ti,W,Ta)(CN) rim solid solution. Least contiguity (C) of the ceramic particles and largest mean free path (λ) of the binder phase was observed for the cermet having TaC and Ni–Co addition. Hardness and fracture toughness of the TiCN based cermets prepared via conventional sintering varied from 14–16 GPa and 8.75–9.25 MPa m1/2 and via SPS technique varied from 15–17 GPa and 8.79–9.51 MPa m1/2. Nano hardness of different phases varied from 9.83 to 26.01 GPa for sintered cermets. Refined carbide size and least fraction of adjacent ceramic phase resulted in improved properties of TaC added TiCN–WC–Ni/Co cermet.

Similar content being viewed by others

References

Ettmayer P, Kolaska H, Lengauer W, and Dreyer K, Int J Ref Met Hard Mater 13 (1995) 343.

Zhang H, Yan J, Zhang X, and Tang S, Int J Ref Met Hard Mater 24 (2006) 236.

Zhang S, Mat Sci Eng, 163 A (1993) 141.

Dusza J, Parilak L, and Slesar M, Ceram Int 13 (1987) 133.

Moskowitz D, and Humenik M. Cemented Titanium Carbide Cutting Tools. 3rd vol. Modern developments in powder metallurgy; (1966).

Sundararajan G, and Suresh Babu P, Trans of The Ind Inst Of Met 62 (2009) 95.

Ricardo H. R. Castro. Overview of Conventional Sintering. 35th vol. Sintering; (2012).

Guillon O, Julian J G, Dargatz B, Kessel T, Schierning G, Rathel J, and Herrmann M, Adv Eng Mater 16 (2014) 830.

Pastor H, Mat Sci Eng A 105 (1988) 401.

Jeon E T, Joardar J, and Kang S, Int J Ref Met Hard Mater 20 (2002) 207.

Borrell A, Salvador M D, Rocha V G, Fernandez A, Aviles M A, and Gotor F J, Mat Res Bulletin 47 (2012) 4487.

Gong J, Pan X, Miao H, and Zhao Z, Mater Sci Eng A 359 (2003) 391.

Gruss W W, in Metals Handbook, 9th edn, vol 16, (ed) Burdes B P, Am Soc Met, Metals Park, (1989), p 90.

Rowcliffe D J, and Hollox G E, J Mater Sci 6 (1971) 1261.

Rowcliffe D J, and Warren W J, J Mater Sci 5 (1970) 345.

Xiong J, Guo Z, Shen B, and Cao D, Mater Des 28 (2007) 1689.

Kiani S, Yang J M, and Kodambaka S, J Am Ceram Soc 98 (2015) 1.

Ahn S Y, Kang S, J Am Ceramic Soc 83 (2000) 1489.

Shetty D K, Wright I G, Mincer P N, and Clauer A H, J Mater Sci 20 (1985) 1873.

Ping F, Hao X W, Yong Z, Xin Y L, and Hua X Y, J Wuhan Univ of Tech Mater Sci 19 (2004) 69.

Kwon W T, Park J S, Kim S W, and Kang S, Int J Mac Tools & Manu 44 (2004) 341.

Manoj Kumar B V M, Basu B, Vizintin O, and Kalin M, J Mat Res 23 (2008) 1214.

Xiong J, Guo Z X, Yang M, and Shen B L, Int J Ref Met Hard Mater 26 (2008) 212.

Hussainova I, Wear 255 (2003) 121.

Alvarez M, and Sanchez J M, Int J Ref Met Hard Mater 25 (2007) 107.

Zheng Y, Wang S, You M, Tana H, and Xiong W, Mater Chem Phys 92 (2005) 64.

Park D S, Lee Y D, and Kang S, J Am Ceram Soc 54 (1999), 3150.

Tretyakov V I, and Mashevskaya V I, P. Meta. Met. Ceram. 38 (1999) 64.

Kumar B V M, Ramkumar J, Basu B, and Kang S, Int J Ref Met Hard Mater 25 (2007) 293.

Krupp F. Hard Alloy for Working Instruments and Tools. French Patent 715148A. (1931) p 2004.

Kieffer R, Ettmayer P, and Freudhofmeier M, Metall 25 (1971) 1335.

lyori Y, and Yokoo H. Patente Cermet Alloys and Composite Mechanical Parts Made by Employing Them. US Patent 4983212 A.(1991) 1.

Liu N, Liu C L, and Zhao X Z, Cem Carbide 11 (1994) 144.

Liu N, Zhao X Z, and Liu C L, Phys Test Chem Anal A-Phys Test, 31 (1995) 13.

Zhang J, Liu C L, and Hu Z H, Powder Metall Technol 15 (1997) 122.

Zackrisson J, and Andren H O, Int J Ref Met Hard Mater 17 (1999) 265.

Ahn S Y, and Kang S, J Am Ceram Soc 83 (2003) 1489.

Zackrisson J, Rollander U, and Andren H O, Metall Mater Trans A 2 (2001) 85.

Liu N, Han C L, Xu Y D, Chao S, Shi M, and Feng J P, Mater Sci Eng A 382 (2004) 122.

Park S, and Kang S, Scripta Mater 52 (2005) 129.

Liu N, Chao S, and Yang H D, Int J Ref Met Hard Mater 24 (2006) 445.

Cardinal S, Malchere A, Garnier V, and Fantozzi G, Int J Ref Met Hard Mater 27 (2009) 521.

Zhang H A, Yan D K, and Tang S W, Rare Met 29 (2010) 528.

Liu Y, Jin Y Z, Yu H J, and Ye J W, Int J Ref Met Hard Mater 29 (2011) 104.

Kim Y S, Kwon W T, Seo M, and Kang S, Int J Preci. Eng.Manf 13 (2012) 941.

Mun S, and Kang S, Powder Metallurgy, 42 (1999) 251.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verma, V., Manoj Kumar, B.V. Processing of TiCN–WC–Ni/Co Cermets via Conventional and Spark Plasma Sintering Technique. Trans Indian Inst Met 70, 843–853 (2017). https://doi.org/10.1007/s12666-017-1069-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1069-y