Abstract

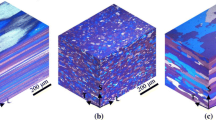

Ultrafine grained AA7075 aluminum alloy (Al–6Zn–2Mg–1Cu), was produced by cryorolling the solutionized samples followed by annealing and peak aging treatments. In the cryorolled and peak aged (CRPA) alloy, the presence of large amount of dislocations acted as nucleation sites for precipitation, resulting in finer and densely distributed precipitates, when compared to its coarse grain peak aged (CGPA) alloy. Potentiodynamic polarization studies revealed increased Epit by about 300 mV for CRPA alloy compared to CGPA alloy, indicating improved corrosion resistance to pitting. Intergranular corrosion tests were performed according to ASTM G-110 and the results revealed no grain boundary attack and improved resistance of CRPA when compared to severe grain boundary attack in CGPA alloy. The improved corrosion resistance in CRPA was mainly attributed to the reduced galvanic couples formation within the alloy due to absence of anodic coarse precipitates along the grain boundaries and the associated precipitate free zones.

Similar content being viewed by others

References

Li X M and Stranik M J, Mater Sci Technol 17 (2001) 1324.

Lendvai J, Mater Sci Forum 217 (1996) 43.

Mingler B, Karnthaler H P, Zehetbauer M and Valiev R Z, Mater Sci Eng A 319 (2001) 242.

Zhao Y H, Liao X Z, Jin Z, Valiev R Z and Zhu Y T, Acta Mater 52 (2004) 4589.

A Statistical Review on Aluminium Shipments by Major Market, 2004. United States and Canada.

Shanmugasundaram T, Murty B S and Subramanya Sarma V, Scr Mater 54 (2006) 2013.

Gopala Krishna K, Nidhi Singh K, Venkateswarlu K and Hari Kumar KC, J Mater Eng Perform 20 (2011) 1569.

Zhao Y H, Liao X Z, Cheng S, Ma E and Zhu Y T, Adv Mater 18 (2006) 2280.

Panigrahi S K and Jayaganthan R, Mater Des 32 (2011) 2172.

Das P, Jayaganthan R and Singh IV, Mater Des 32 (2011) 1298.

Panigrahi S K and Jayaganthan R, Mater Des 32 (2011) 3150.

Gopala Krishna K, Siva Prsad K, Venkateswarlu K and Hari Kumar K C, Mater Sci Eng A 535 (2012) 129.

Naga Krishna N, Tejas R, Siva Prasad K and Venkateswarlu K, Mater Design 52 (2013) 785.

Gopala Krishna K, Siva Prasad K, Sankara Narayanan T S N and Hari Kumar K C, Corros Sci 60 (2012) 82.

Siva Prasad K, Swarnalatha V, Ravi Kumar V V and Muthupandi V, Anti Corros Methods Mater 57 (2010) 18.

El-Amoush A S, Mater Chem Phys 126 (2011) 607.

Hadzima B, Janecek M, Hellmig R J, Kutnyakova Y and Estrin Y, Mater Sci Forum 503 (2006) 883.

Vinogradov A, Miyamoto H, Mimaki T and Hashimoto S, Ann Chim 27 (2002) 65.

Chung M K, Choi Y S, Kim J G, Kim Y M and Lee J C, Mater Sci Eng A 366 (2004) 282.

Huang TS, On the intergranular corrosion of 7XXX aluminum alloys, PhD thesis, The Ohio State University (2005).

Clark R Jr, Coughran B, Traina I, Hernandez A, Scheck T, Etuk C, Peters J, Lee E W, Ogren J and Es-Said O S, Eng Fail Anal 12 (2005) 520.

Andreatta F, Terryn H and de Wit J H W, Corros Sci 45 (2003) 1733.

Jayaganthan R and Panigrahi S K, Mater Sci Forum 584 (2008) 911.

Gao N, Starink M J, Xu C and Langdon T G, Mater Forum 28 (2004) 856.

Garcia-Cordovilla C and Louis E, Mater Sci Eng A 132 (1991) 135.

Starink M J and Wang S C, Acta Mater 51 (2003) 5131.

Dey S, Gunjan M K and Chattoraj I, Corros Sci 50 (2008) 2895.

Panigrahi S K and Jayaganthan R, Mater Sci Forum 584 (2008) 734.

Engdahl T, Hansen V, Warren P J and Stiller K, Mater Sci Eng A 327 (2002) 59.

Avitzur B, Metall Trans 4 (1973) 383.

Cheng S, Zhao Y H, Zhu Y T and Ma E, Acta Mater 55 (2007) 5822.

Jayaganthan R, Brokmeier H G, Schwebke B and Panigrahi S K, J Alloys Compd 496 (2010) 183.

Chemingui M, Khitouni M, Jozwiak K, Mesmacque G and Kolsi A. Mater Des 31 (2010) 3134.

Panigrahi S K, Jayaganthan R and Pancholi V, Mater Des 30 (2009) 1897.

Hatch J E, Aluminum: Properties and Physical Metallurgy, ASM, Metals Park (1983).

Wei R P, Liao C M and Gao M, Metall Mater Trans A 29 (1998) 1153.

Gao M, Feng C R, and Wei R P, Metall Mater Trans A 29 (1998) 1145.

Puiggali M, Zielinski A, Olive J M, Renauld E, Desjardins D, and Cid M, Corros Sci 40 (1998) 805.

Meng Q and Frankel G S, J Electrochem Soc 151 (2004) 271.

Ramgopal T, Gouma P I and Frankel G S, Corrosion 58 (2002) 687.

Ramgopal T, Schmutz P and Frankel G S, J Electrochem Soc 148 (2001) B348.

Acknowledgements

The first author (KGK) expresses his sincere thanks to The Director, CSIR-National Metallurgical Laboratory, Jamshedpur, for extending all the necessary support to carry out this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gopala Krishna, K., Das, G., Venkateswarlu, K. et al. Studies on Aging and Corrosion Properties of Cryorolled Al–Zn–Mg–Cu (AA7075) Alloy. Trans Indian Inst Met 70, 817–825 (2017). https://doi.org/10.1007/s12666-017-1064-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1064-3