Abstract

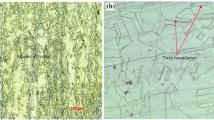

Strength and ductility of fusion zone of metastable β titanium alloy welds can be improved by choosing suitable fillers. This paper reports the effects of using CP-Ti filler on the microstructural and mechanical properties of Ti-15-3 weldments. Full penetration autogenous and CP-Ti filler welds were produced by pulsed gas tungsten arc welding. X-ray diffraction analysis revealed small amounts of α-Ti phase in the diffraction pattern obtained for welds prepared using CP-Ti filler. Transmission electron microscopy analysis showed presence of grain boundary and intragranular α in the fusion zone of the welds prepared using CP-Ti filler. The welds prepared with CP-Ti filler showed higher hardness, higher UTS and lower % strain compared to autogenous welds.

Similar content being viewed by others

References

Boyer R R, Mater Sci Eng A 213 (1996) 103.

Lutjering G, Mater Sci Eng A 243 (1998) 32.

Baeslack III W A and Banas C M, Welding Research Supplement, July (1981) 121.

Balasubramanian M, Jayabalan V, and Balasubramanian V, Mater Lett 62 (2008) 1102.

Hallum D L, and Baeslack III W A, WRC Bulletin 339 (1990) 326.

Balasubramanian M, Jayabalan V, and Balasubramanian V, J Manuf Sci Eng 131 (2009)

Chen J, and Pan C, Trans Nonferrous Met Soc China 21 (2011) 1506.

Sundaresan S, Janaki Ram G D, and Reddy G M, Mater Sci Eng A 262 (1999) 88.

Kishore Babu N, Sundara S G, Mythili R, and Saroja S, Mater Charact 58 (2007) 581.

Balachandar K, Subramanya Sarma V, Pant B, and Phanikumar G, Metall Mater Trans A 40 (2009) 2685.

Balasubramanian V, Jayabalan V, and Balasubramanian M, Mater Des 29 (2008) 1459.

Yang M, Qi B, Cong B, Liu F, and Yang Z, Int J Adv Manuf Technol 68 (2013) 19.

Greenfield M A, and Pierce C M, Welding Research Supplement, Nov (1973) 524.

Kuroda T, Horinouchi T, Iwagi O, Mori K, and Matsuda F, Trans JWRI 19 (1990) 79.

Barreda J L, Santamaria F, Azpiroz X, Irisarri A M, and Varona J M, Vacuum 62 (2001) 143.

Irisarri A M, Barreda J L, and Azpiroz X, Vacuum 84 (2010) 143.

Shariff T, Cao X, Chromik R R, Wanjara P, Cuddy J, and Birur A, J Mater Sci 47 (2012) 866.

Lippold J C, Welding Metallurgy and Weldability, John Wiley and Sons, NJ (2003) p 14.

Kou S, Welding Metallurgy, Second Edition, John Wiley and Sons, NJ (2003) p 170.

Kim S J, Choe B H, and Lee Y T, in Metallurgy and Technology of Practical Titanium Alloys, (eds) Fujishiro S, Eylon D, and Kishi T, TMS, Warrendale (1994), p 167.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Anis, A.L., Talari, M.K., Mohd Arif, I.A. et al. Microstructure and Mechanical Properties of Ti-15-3 Alloy Gas Tungsten Arc Welds Prepared Using CP-Titanium Filler. Trans Indian Inst Met 70, 685–690 (2017). https://doi.org/10.1007/s12666-017-1049-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-017-1049-2