Abstract

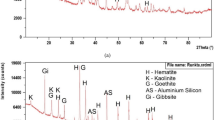

The pelletisation study of magnetite iron ore fines starts with green balling using limestone and bentonite as additives. Heating cycle of iron ore pellets is one of the prime segments of the whole pelletisation process. Drying, pre-heating, firing and cooling processes are collectively named as heating cycle of the process. A temperature profile is maintained throughout the induration process to meet the required specification of the pellet quality. This paper emphasizes on the effect of temperature profile on the mineralogical, physical and chemical properties of fired pellet in the heating cycle. This study includes the green balling and heating cycle at different temperatures from 800 to 1250 °C in batch processes of magnetite iron ore fines. The mineralogical phase conversion mainly from magnetite to hematite at different temperatures is evaluated by XRD study. The microstructural characterisation, compressive strength and chemical analysis of the indurated pellets are used to analyse the effect of increasing temperature during pellet induration.

Similar content being viewed by others

References

Mayer K, Pelletizing of Iron Ores, Springer, Berlin (1980).

Kawatra S K, and Ripke S J, Int J Miner Process 65 (2002) 165.

Fu J, Cheong Y, Reynolds G, Salman A, and Hounslow M, Powder Technol 140 (2004) 209.

Mohindra M, Prusti P, Sahu S N, Beuria P C, Sahu A K, and Biswal S K, in International Symposium on MRMMPI, Bhubaneswar (2013), p 143.

Sastry K V S, Dontula P, and Hosten C, Powder Technol 130 (2003) 231.

Liang R Q, Yang S, Yan F S, and He J C, J Iron Steel Res Int 20 (2013) 16.

Kumar T K S, Investigation of Sintering Kinetics of Magnetite pellets during Induration, Ph D Thesis, Luleå University of Technology, (2015).

Kumar T K S, Viswanathan N N, Ahmed H M, Andersson C, and Björkman B, Metall Mater Trans B 47 (2016) 309.

Forsmo S P E, Forsmo S E, Samskog P O, and Björkman B M T, Powder Technol 183 (2008) 247.

Forsmo S, Influence of Green Pellet Properties on Pelletizing of Magnetite Iron Ore, Doctoral Thesis, Luleå University of Technology Department of Chemical Engineering and Geosciences, Division of Process Metallurgy (2007).

Guo H W, Bai J L, Zhang J L, and Li H G, J Iron Steel Res Int 21 (2014) 9.

Cho H J, Tang M, and Pistorius P C, Metall Mater Trans B 45B (2014) 1213.

Tang M, Cho H J, and Pistorius P C, Metall Mater Trans B 45B (2014) 1304.

Kapur P C, and Fuerstenau D W, Trans AIME 229 (1964) 348.

Sastry K V S, and Fuerstenau D W, Powder Technol 7 (1973) 97.

Kapur P C, Adv Chem Eng 10 (1978) 55.

Abouzeid A Z M, Seddik A A, and El-Sinbawy H A, Powder Technol 24 (1979) 229.

Gupta R C, Theory and Laboratory Experiments in Ferrous Metallurgy, PHI Learning Private Limited (2010).

Sivrikaya O, and Arol A I, Int J Miner Process 110–111 (2012) 90.

Dwarapudi S, Devi T U, Rao S M, and Ranjan M, ISIJ Int 48 (2008) 768.

Umadevi T, Kumar P, Lobo N F, Mahapatra P C, Prabhu M, and Ranjan M, Steel Res Int 80 (2009) 709.

Acknowledgements

The authors are thankful to Prof. B.K. Mishra, Director of CSIR-Institute of Minerals and Materials Technology, Bhubaneswar for giving permission to publish this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prusti, P., Nayak, B.K. & Biswal, S.K. Study of Temperature Profile in the Induration of Magnetite Iron Ore Pellets. Trans Indian Inst Met 70, 453–462 (2017). https://doi.org/10.1007/s12666-016-1011-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-1011-8