Abstract

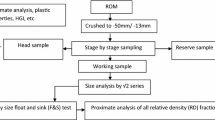

Low volatile coking (LVC) coal reserves have become the key for sustaining the coking coal production in India. Because of high ash content and difficult washability characteristics coking coal in India is usually cleaned at 16–18% ash content. To obtain a reasonable yield at this ash level, LVC coal needs to be crushed to less than at least 13 mm before cleaning. LVC coal when crushed to −13 mm, depending on HGI and crushers used fines (−0.5 mm) could constitute 15–25% of the crushed coal. Limited study has so far been done on flotation characteristics of LVC coal fines, though flotation is the only method used in India to clean the coking coal fines. The work presented here after discusses the difficulties associated with the flotation of LVC coal fines arising out of its petrographic composition, complicated liberation characteristics, collector dependency, etc.

Similar content being viewed by others

References

Dey S, A Comparative Study of Frother Performance in Coal Flotation, PhD Thesis, Indian School of Mines (2004).

SAIL (Steel Authority of India Ltd), Personal Communication (2009).

Gouricharan T, Sharma K K, Chattopadhyay U S, Sinha K M K, Chattopadhyay P C, Jha G S, Kabiraj S K, Haldar D D, Das T K, and Ghosh N K, in International Conference on Coking Coals and Coke Making: Challenges and Opportunities, Washability and Pilot Plant Studies to Generate Bulk Cleans at Desired Qualities from LVC Coal of Jharia Coalfields, (eds) Vijayavergia R K, Ray J K, Tirkey S, Viva Books, New Delhi (2009), p 219.

Bhattacharya S, Personal Research (2009).

Dell C C, Release analysis, A new tool for ore dressing research, in recent developments in mineral dressing, IMM (1953) p 75.

Dell C C, J Inst Fuel 37 (1964) 149.

Cavallaro J A, and Deurbrouck A W, Froth Flotation Washability Data of Various Appalachian Coals Using the Timed Release Analysis Technique, USBM Report of Investigation No. 6652 (1965).

BS 7530, Methods for Froth flotation testing of hard coal, Part 2, Evaluation of flotation characteristics, published by British Standard Institution, London (1994).

Nicol S K, Bensley C N, The K C, and Firth B A, The Estimation of Coal Flotation Response, Proceedings, Congress for Improving Froth Flotation of Coal, (ed) Membrey W, Australian Coal Industry Research Laboratories, (1983) p 116.

Forrest W R, Adel G T, and Yoon R H, Coal Prep 14 (1994) 13.

Mohanty M K, Honakar R Q, and Ho K, Coal Prep (1998) 19.

Brown D W, and Hall S T, Fuel 78 (1999) 1621.

Arnold B J, and Aplan F F, Fuel 68 (1989) 651.

Sen K, and Choudhuri S G, Beneficiation of Difficult to Wash Coals: Development and Prospects, XII International Coal Preparation Congress, (ed) Blaschke W S, Gordon and Breach, Amsterdam (1994), p 957.

Singh A K, Sahay A N, and Mishra H K, , MineTech 32 (2011) 3.

Chattopadhyay U S, Singh K M P, Kabiraj S K, Choudhuri S, Sharma K K, and Gouricharan T, Beneficiation of Difficult to Wash Indian Coking Coal- Challenges before Indian Steel Sectors, XXV International Mineral Processing Congress, New Delhi (2012), paper no. 961.

Caldeira J, and Redonda V, Low Volatile Jellinbah Semi Soft Coking Coal—An Alternative Coal for Coke Blending, Jellinbah Resources Pty Ltd. CAN 010825205 (1998). www.jellinbah.com.au.

Arnold B J, and Aplan F F, Coal Froth Flotation: The Response of Coal and Mineral Particles to Reagent and Circuit Variations, Advances in Mineral Processing, Society of Mining Engineers (1986), p 351.

Aplan F F, Min Eng 45 (1993) 83.

Malvadkar S B, Forbes S, and Mc Gurl, G V, Coal Resources: Formation of. In: Encyclopedia of Energy, (ed) Cleveland C J, Elsevier, New York (2014), p 529.

Divya Jyoti, Characterization and assessment of beneficiation and utilization potential of selected seams of low volatile coking coal of Jharia and Bokaro coalfield, PhD thesis, Indian School of Mines, Dhanbad (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhattacharya, S., Jyoti, D., Sahu, L. et al. Flotation of Low Volatile Coking Coal Fines. Trans Indian Inst Met 70, 421–432 (2017). https://doi.org/10.1007/s12666-016-0996-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0996-3