Abstract

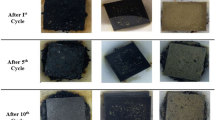

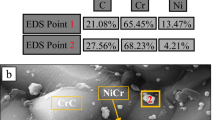

9Cr–1Mo steel has been proposed as the container material for the electrorefining process of pyrochemical reprocessing of spent metallic fuels from the future sodium cooled fast breeder reactors. The electrorefining process was carried out using LiCl–KCl–UCl3 molten salt as the electrolyte at 500 °C under argon atmosphere. To protect the electrorefining vessel, made of 9Cr–1Mo steel from the attack by the electrolyte, yttria stabilized zirconia (YSZ) ceramic coating was deposited on 9Cr–1Mo steel by thermal spray process. The corrosion behavior of 9Cr–1Mo steel with and without YSZ coating was evaluated in LiCl–KCl–UCl3 molten salt at 600 °C under argon atmosphere for various durations (100, 250, 500 and 1000 h). The results revealed that with increase in exposure time, the weight loss of uncoated 9Cr–1Mo steel samples increased, while YSZ coated 9Cr–1Mo steel samples exhibited insignificant weight loss. SEM examination of exposed uncoated 9Cr–1Mo steel samples showed Cr depletion on the surface and formation of chromium based oxides as corrosion products. After the corrosion experiment, SEM/EDS and XRD analyses of both coated and uncoated samples showed the presence of Fe–Cr and UO2.

Similar content being viewed by others

References

Raj B, Energy Procedia 7 (2011) 186.

Nagarajan K, Reddy B P, Ghosh S, Ravisankar G, Mohandas K S, Kamachi Mudali U, Kutty K V G, Kasiviswanathan K V, Anand Babu C, Kalyanasundaram P, Vasudeva Rao P R and Raj B, Energy Procedia 7 (2011) 431.

Laidler J J, Battles J E, Miller W E, Ackerman J P and Carls E L, Prog Nucl Energy 31 (1997) 131.

Ravi Shankar A, Thyagarajan K and Kamachi Mudali U, Corrosion 69 (2013) 655.

Herman H, Sampath S and McCune R, Trends MRS Bull 25 (2000) 17.

Ravi Shankar A, Mathiya S, Thyagarajan K and Kamachi Mudali U, Metall Mater Trans A 41A (2010) 1815.

Ravi Shankar A, Kamachi Mudali U, Sole R, Khatak H S and Raj B, J Nucl Mater 372 (2008) 226.

Sure J, Ravi Shankar A, Ramya S, and Kamachi Mudali U, Ceram Int 38 (2012) 2803.

Sure J, Jagadeeswara Rao Ch, Venkatesh P, Prabhakara Reddy B, Mallika C and Kamachi Mudali U, Ceram Int 40 (2014) 6509.

Jagadeeswara Rao Ch, Ravi Shankar A, Mallika C and Kamachi Mudali U, Ceram Int 41 (2015) 3128.

Periasamy P, Hurley M F, Marx B M, Simpson M F and Butt D P, J Nucl Mater 405 (2010) 266.

Jagadeeswara Rao Ch, Ravi Shankar A, Ajikumar P K, Kamruddin M, Mallika C and Kamachi Mudali U, Corrosion 71 (2015) 502.

Nakayoshi A, Kitawaki S, Fukushima M, Murakami T and Kurata M, J Nucl Mater 441 (2013) 468.

Davies W and Gray W, Talanta 11 (1964) 1203.

Kane R D, in ASM Handbook, Volume 13A: Corrosion: Fundamentals, Testing, and Protection, (eds) Cramer S D, Covino Jr B S, ASM International, Materials Park (2003), p 216.

Molten salt corrosion, in High Temperature Corrosion and Materials Applications, (ed) Y Lai George, ASM International, Materials Park (2007), p 409.

Birks N, Meier G H and Pettit F S, Introduction to the High Temperature Oxidation of Metals, Cambridge University Press, Cambridge (2006).

Knacke O, Kubaschewski O, Hesselmann K, Thermochemical Properties of Inorganic Substances, 2nd Ed, Springer, New York (1991).

Acknowledgments

The authors acknowledge Dr. B. Prabhakara Reddy, Scientific Officer ‘H’ and Shri. P. Venkatesh, Scientific Officer ‘F’, Chemistry Group, IGCAR for providing the molten salt.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jagadeeswara Rao, C., Ismail, T.P., Ravi Shankar, A. et al. Corrosion Behaviour of Uncoated and Ceramic Coated 9Cr–1Mo Steel in Molten LiCl–KCl–UCl3 Salt. Trans Indian Inst Met 70, 1359–1367 (2017). https://doi.org/10.1007/s12666-016-0906-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0906-8