Abstract

Purpose

Spent liquors produced in the pulping industry contain dissolved lignocellulosic macromolecular components that are currently burned or treated in wastewater treatment systems. However, they can be isolated by flocculation to make added-value products. In this work, lignin and hemicelluloses were extracted from spent liquor (SL) of a thermomechanical pulping process (TMP) and treated by polydiallyldimethylammonium chloride (PDADMAC).

Methodology

The flocculation of lignocellulosic compounds of SL with three different molecular weights of PDADMAC was studied comprehensively in this work. The settlement of the generated flocs was also investigated by means of advanced techniques, and the results were related to the characteristics of PDADMAC and lignocellulosic compounds.

Results

The maximum removals of lignin (57%) and hemicellulose (36%) were achieved by larger PDADMAC with a molecular weight of 1045 kg/mol at the dosages of 100 mg/L and 80 mg/L, respectively. The properties of lignin and hemicelluloses, as well as zeta potential and focused beam reflectance measurement (FBRM) analyses, confirmed that the flocculation of lignin was mainly based on charge interaction, while that of hemicellulose was based on bridging mechanism. PDADMAC/pure lignin system showed a faster sedimentation rate with more compact flocs than both PDADMAC/pure hemicellulose and PDADMAC/industrial SL (TMP) systems. The PDADMAC/hemicellulose system had flocs with the loosest structure and poorest settling performance. The results of this study provide a means to extract and use lignocellulosic compounds of spent liquor via selective flocculation and separation strategies. Lignin/PDADMAC flocs and hemicellulose/PDADMAC flocs can be separated from their solutions by sedimentation and filtration, respectively.

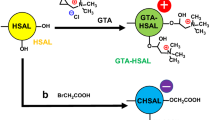

Graphic Abstract

Similar content being viewed by others

References

Laurichesse, S., Avérous, L.: Chemical modification of lignins: towards biobased polymers. Prog. Polym. Sci. 39, 1266–1290 (2014)

Zhu, H., Luo, W., Ciesielski, P.N., Fang, Z., Zhu, J., Henriksson, G., Himmel, M.E., Hu, L.: Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 116, 9305–9374 (2016)

Patel, M., Kumar, A.: Production of renewable diesel through the hydroprocessing of lignocellulosic biomass-derived bio-oil: a review. Renew. Sustain. Energy Rev. 58, 1293–1307 (2016)

Sharma, H.K., Xu, C., Qin, W.: Biological pretreatment of lignocellulosic biomass for biofuels and bioproducts: an overview. Waste Biomass Valoriz. 10, 235–251 (2019)

Hubbe, M.A., Alén, R., Paleologou, M., Kannangara, M., Kihlman, J.: Lignin recovery from spent alkaline pulping liquors using acidification, membrane separation, and related processing steps: a review. BioResources 14, 2300–2351 (2019)

Andersson, K.I., Eriksson, M., Norgren, M.: Removal of lignin from wastewater generated by mechanical pulping using activated charcoal and fly ash: adsorption isotherms and thermodynamics. Ind. Eng. Chem. Res. 50(13), 7722–7732 (2011)

Liao, B., Bokhary, A., Cui, L., Lin, H.: A Review of membrane technology for integrated forest biorefinery. J. Membr. Sci. Res. 3, 120–141 (2017)

Bokhary, A., Leitch, M., Gao, W.J., Fatehi, P., Liao, B.Q.: Separation of hemicelluloses and lignins from synthetic hydrolyzate and thermomechanical pulp mill process water via liquid-liquid extraction. Sep. Purif. Technol. 215, 508–515 (2019)

Mussatto, S.I., Fernandes, M., Roberto, I.C.: Lignin recovery from brewer’s spent grain black liquor. Carbohydr. Polym. 70, 218–223 (2007)

Solikhin, A., Hadi, Y.S., Massijaya, M.Y., Nikmatin, S.: Novel isolation of empty fruit bunch lignocellulose nanofibers using different vibration milling times-assisted multimechanical stages. Waste Biomass Valoriz. 8, 2451–2462 (2017)

Qu, J.: Research progress of novel adsorption processes in water purification: a review. J. Environ. Sci. 20(1), 1–13 (2008)

Sharma, B.R., Dhuldhoya, N.C., Merchant, U.C.: Flocculants: an ecofriendly approach. J. Polym. Environ. 14, 195–202 (2006)

Razali, M.A.A., Ahmad, Z., Ahmad, M., Ariffin, A.: Treatment of pulp and paper mill wastewater with various molecular weight of polyDADMAC induced flocculation. Chem. Eng. J. 166, 529–535 (2011)

Lee, C.S., Robinson, J., Chong, M.F.: A review on application of flocculants in wastewater treatment. Process Saf. Environ. Prot. 92, 489–508 (2014)

Domínguez-Robles, J., del Valle Palenzuela, M., Sánchez, R., Loaiza, J.M., Espinosa, E., Rosal, A., Rodríguez, A.: Coagulation–flocculation as an alternative way to reduce the toxicity of the black liquor from the paper industry: thermal valorization of the solid biomass recovered. Waste Biomass Valoriz. (2019). https://doi.org/10.1007/s12649-019-00795-7

Kamali, M., Khodaparast, Z.: Review on recent developments on pulp and paper mill wastewater treatment. Ecotoxicol. Environ. Saf. 114, 326–342 (2015)

Wang, J.P., Chen, Y.Z., Wang, Y., Yuan, S.J., Yu, H.Q.: Optimization of the coagulation-flocculation process for pulp mill wastewater treatment using a combination of uniform design and response surface methodology. Water Res. 45, 5633–5640 (2011)

Wong, S., Teng, T., Ahmad, A., Zuhairi, A., Najafpour, G.: Treatment of pulp and paper mill wastewater by polyacrylamide (PAM) in polymer induced flocculation. J. Hazard. Mater. 135, 378–388 (2006)

Sun, Y., Liu, Z., Fatehi, P.: Flocculation of thermomechanical pulping SL with polydiallyldimethylammonium chloride. J. Environ. Manag. 200, 275–282 (2017)

Shaikh, S.M.R., Nasser, M.S., Hussein, I., Benamor, A., Onaizi, S.A., Qiblawey, H.: Influence of polyelectrolytes and other polymer complexes on the flocculation and rheological behaviors of clay minerals: a comprehensive review. Sep. Purif. Technol. 187, 137–161 (2017)

Dao, V.H., Cameron, N.R., Saito, K.: Synthesis, properties and performance of organic polymers employed in flocculation applications. Polym. Chem. 7, 11–25 (2016)

He, W., Nan, J., Li, H., Li, S.: Characteristic analysis on temporal evolution of floc size and structure in low-shear flow. Water Res. 46, 509–520 (2012)

Harif, T., Khai, M., Adin, A.: Electrocoagulation versus chemical coagulation: coagulation/flocculation mechanisms and resulting floc characteristics. Water Res. 46, 3177–3188 (2012)

Hribersek, M., Zajdela, B., Hribernik, A., Zadravec, M.: Experimental and numerical investigations of sedimentation of porous wastewater sludge flocs. Water Res. 45, 1729–1735 (2011)

Ren, P., Nan, J., Zhang, X., Zheng, K.: Analysis of floc morphology in a continuous-flow flocculation and sedimentation reactor. J. Environ. Sci. 52, 268–275 (2017)

Yang, R., Li, H., Huang, M., Yang, H., Li, A.: A review on chitosan-based flocculants and their applications in water treatment. Water Res. 95, 59–89 (2016)

Wei, H., Gao, B., Ren, J., Li, A., Yang, H.: Coagulation/flocculation in dewatering of sludge: a review. Water Res. 143, 608–631 (2018)

Pokhrel, D., Viraraghavan, T.: Treatment of pulp and paper mill wastewater: a review. Sci. Total Environ. 333, 37–58 (2004)

Liu, Z., Fatehi, P., Jahan, M.S., Ni, Y.: Separation of lignocellulosic materials by combined processes of pre-hydrolysis and ethanol extraction. Bioresour. Technol. 102, 1264–1269 (2011)

Martin, M.C.T., Morgano, M.A., Vicente, E., Baggio, S.R., Rodriguez-Amaya, D.B.: Physicochemical composition of bee pollen from eleven Brazilian states. J. Apic. Sci. 55, 107–116 (2011)

Wang, S., Hou, Q., Kong, F., Fatehi, P.: Production of cationic xylan–METAC copolymer as a flocculant for textile industry. Carbohydr. Polym. 124, 229–236 (2015)

Millard, M.M., Wolf, W.J., Dintzis, F.R., Willett, J.L.: The hydrodynamic characterization of waxy maize amylopectin in 90% dimethyl sulfoxide–water by analytical ultracentrifugation, dynamic, and static light scattering. Carbohydr. Polym. 39, 315–320 (1999)

Kim, T.H.: Comparison of inhibition effects of various isolated lignins on enzymatic hydrolysis of cellulose. Korean J. Chem. Eng. 29, 82–88 (2012)

Yang, H., Kang, W., Yu, Y., Yin, X., Wang, P., Zhang, X.: A new approach to evaluate the particle growth and sedimentation of dispersed polymer microsphere profile control system based on multiple light scattering. Powder Technol. 315, 477–485 (2017)

Jacobs, A., Dahlman, O.: Characterization of the molar masses of hemicelluloses from wood and pulps employing size exclusion chromatography and matrix-assisted laser desorption ionization time-of-flight mass spectrometry. Biomacromol 2, 894–905 (2001)

Thakur, V.K., Thakur, M.K., Raghavan, P., Kessler, M.R.: Progress in green polymer composites from lignin for multifunctional applications: a review. ACS Sustain. Chem. Eng. 2, 1072–1092 (2014)

Gupta, P., Goring, D.: Physicochemical studies of alkali lignins: III Size and shape of the macromolecule. Can. J. Chem. 38, 270–279 (1960)

Vainio, U., Maximova, N., Hortling, B., Laine, J., Stenius, P., Simola, L.K., Gravitis, J., Serimaa, R.: Morphology of dry lignins and size and shape of dissolved kraft lignin particles by X-ray scattering. Langmuir 20, 9736–9744 (2004)

Li, X., Shi, X., Wang, M., Du, Y.: Xylan chitosan conjugate: a potential food preservative. Food Chem. 126, 520–525 (2011)

Kerr, A.J., Goring, D.: The role of hemicellulose in the delignification of wood. Can. J. Chem. 53, 952–959 (1975)

Tarasov, D., Leitch, M., Fatehi, P.: Lignin–carbohydrate complexes: Properties, applications, analyses, and methods of extraction: a review. Biotechnol. Biofuels 11, 269 (2018)

Yasarla, L.R., Ramarao, B.V.: Lignin removal from lignocellulosic hydrolyzates by flocculation with polyethylene oxide. J. Biobased Mater. Bioenergy 7, 684–689 (2013)

Oveissi, F., Sitter, T., Fatehi, P.: PDADMAC as a flocculant for lignosulfonate of NSSC pulping process. Biotechnol. Prog. 32(3), 686–691 (2016)

Liu, X., Fatehi, P., Ni, Y.: Removal of inhibitors from pre-hydrolysis liquor of kraft-based dissolving pulp production process using adsorption and flocculation processes. Bioresour. Technol. 116, 492–496 (2012)

Jiang, J., Li, Z., Fu, Y., Wang, Z., Qin, M.: Enhancement of colloidal particle and lignin removal from pre-hydrolysis liquor of aspen by a combination of pectinase and cationic polymer treatment. Sep. Purif. Technol. 199, 78–83 (2018)

Shi, H., Fatehi, P., Xiao, H., Ni, Y.: Optimizing the poly ethylene oxide flocculation process for isolating lignin of prehydrolysis liquor of a kraft-based dissolving pulp production process. Ind. Eng. Chem. Res. 51, 5330–5335 (2012)

Nasser, M., James, A.: The effect of polyacrylamide charge density and molecular weight on the flocculation and sedimentation behaviour of kaolinite suspensions. Sep. Purif. Technol. 52, 241–252 (2006)

Yuan, Y., Zhang, H., Pan, G.: Flocculation of cyanobacterial cells using coal fly ash modified chitosan. Water Res. 97, 11–18 (2016)

Ariffin, A., Razali, M.A.A., Ahmad, Z.: PolyDADMAC and polyacrylamide as a hybrid flocculation system in the treatment of pulp and paper mills waste water. Chem. Eng. J. 179, 107–111 (2012)

Norgren, M., Edlund, H., Wågberg, L.: Aggregation of lignin derivatives under alkaline conditions. Kinetics and aggregate structure. Langmuir 18, 2859–2865 (2002)

Blake, J.D., Richards, G.N.: Evidence for molecular aggregation in hemicelluloses. Carbohydr. Res. 18, 11–21 (1971)

Chen, Y., Fan, D., Han, Y., Lyu, S., Lu, Y., Li, G., Jiang, F., Wang, S.: Effect of high residual lignin on the properties of cellulose nanofibrils/films. Cellulose 25, 6421–6431 (2018)

Carmona, C., Langan, P., Smith, J.C., Petridis, L.: Why genetic modification of lignin leads to low-recalcitrance biomass. Phys. Chem. Chem. Phys. 17, 358–364 (2015)

Olsson, A.-M., Salmén, L.: The association of water to cellulose and hemicellulose in paper examined by FTIR spectroscopy. Carbohydr. Res. 339(4), 813–818 (2004)

Gravitis, J., Erins, P.: Topological and conformational structure and macroscopic behavior of lignin. Paper presented at cellulose conference, Syracuse, NY, USA, 24 May 1982

Wiśniewska, M., Terpiłowski, K., Chibowski, S., Urban, T., Zarko, V.I., Gun'ko, V.M.: Effect of polyacrylic acid (PAA) adsorption on stability of mixed alumina-silica oxide suspension. Powder Technol. 233, 190–200 (2013)

Dyer, K.R., Manning, A.J.: Observation of the size, settling velocity and effective density of flocs, and their fractal dimensions. J. Sea Res. 41, 87–95 (1999)

Gregor, J.E., Nokes, C.J., Fenton, E.: Optimising natural organic matter removal from low turbidity waters by controlled pH adjustment of aluminium coagulation. Water Res. 31, 2949–2958 (1997)

Curran, K.J., Hill, P.S., Milligan, T.G.: Time variation of floc properties in a settling column. J. Sea Res. 49, 1–9 (2003)

Wu, Z., Zhu, Y., Huang, W., Zhang, C., Li, T., Zhang, Y., Li, A.: Evaluation of flocculation induced by pH increase for harvesting microalgae and reuse of flocculated medium. Bioresour. Technol. 110, 496–502 (2012)

Tanneru, C.T., Rimer, J.D., Chellam, S.: Sweep flocculation and adsorption of viruses on aluminum flocs during electrochemical treatment prior to surface water microfiltration. Environ. Sci. Technol. 47, 4612–4618 (2013)

Costine, A., Cox, J., Travaglini, S., Lubansky, A., Fawell, P., Misslitz, H.: Variations in the molecular weight response of anionic polyacrylamides under different flocculation conditions. Chem. Eng. Sci. 176, 127–138 (2018)

Li, P., Pelton, R.: Wood pulp washing 1. Complex formation between kraft lignin and cationic polymers. Colloid Surf. 64, 217–222 (1992)

Henriksson, G., Lawoko, M., Martin, M.E.E., Gellerstedt, G.: Lignin-carbohydrate network in wood and pulps: a determinant for reactivity. Holzforschung 61, 668–674 (2007)

Lappan, R.E., Pelton, R., McLennan, I., Patry, J., Hrymak, A.N.: Kraft lignin−poly (DADMAC) precipitate formation. Ind. Eng. Chem. Res. 36, 1171–1175 (1997)

Acknowledgements

Supports from NSERC, Canada Research Chairs, NOHFC-Industrial Research Chair and Canadian Foundation for Innovation programs are acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, W., Sun, Y., Kong, F. et al. Aggregation and Sedimentation Performance of Lignin and Hemicellulose Derived Flocs in the Spent Liquor of Thermomechanical Pulping Process. Waste Biomass Valor 12, 773–786 (2021). https://doi.org/10.1007/s12649-020-01005-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01005-5