Abstract

Purpose

Agro-industrial waste, being biodegradable and environmentally-benign, is a sustainable resource for edible film production. Edible films were fabricated from by-products, prickly pear peel mucilage (PPM) and potato husk starch (PHS), and characterised for their physical–chemical properties.

Methods

Various films were prepared by varying the PPM, PHS and glycerine (plasticiser) while maintaining a constant amount of vinegar (acidifying agent).

Results

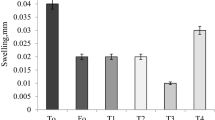

Results showed that the formulation composition influenced the properties of the films. High concentrations of PPM and glycerine led to films with higher thickness, opacity, moisture and water retention capacity (WRC), and the percentage of water solubility (% WS) was influenced by the PHS content. All edible films presented very low water permeability (WP), and thereby good barrier properties. The WS, WRC and WP were closely associated with the PPM and glycerine contents. Consequently, the FTIR and SEM analyses showed similarities between the spectra and images.

Conclusion

The preparation of edible films from agro-industrial wastes, along with their specific application in food packaging, especially for fresh fruits and vegetables, contributes to sustainable alternatives due to the recovery and reuse of the processing residues.

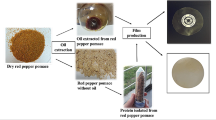

Graphic Abstract

Similar content being viewed by others

References

Debeaufort, F., Quezada-Gallo, J.A., Voilley, A.: Edible films and coatings: tomorrow's packagings: a review. Crit. Rev. Food Sci. Nutr. 38(4), 299–313 (1998). https://doi.org/10.1080/10408699891274219

Cha, D.S., Chinnan, M.S.: Biopolymer-based antimicrobial packaging: a review. Crit. Rev. Food Sci. Nutr. 44(4), 223–237 (2004). https://doi.org/10.1080/10408690490464276

Kester, J.J., Fennema, O.: An edible film of lipid and cellulose ethers: barriers properties to moisture vapor transmission and structure evaluation. J. Food Sci. 54(6), 1383–1389 (1989). https://doi.org/10.1111/j.1365-2621.1989.tb05118.x

Pavlath, A.E., Orts, W.: Edible films and coatings: why, what, and how?. In: Hurber, K.C., Embuscado, M. (eds.) Edible Films and Coatings for Food Applications, pp. 1–23. Springer, New York (2009). https://doi.org/10.1007/978-0-387-92824-1_1

Olivas, G.I., Barbosa-Cánovas, G.: Edible films and coatings for fruits and vegetables. In: Hurber, K.C., Embuscado, M. (eds.) Edible Films and Coatings for Food Applications, pp. 211–244. Springer, New York (2009). https://doi.org/10.1007/978-0-387-92824-1_7

Allegra, A., Inglese, P., Sortino, G., Settanni, L., Todaro, A., Liguori, G.: The influence of Opuntia ficus-indica mucilage edible coating on the quality of ‘Hayward’ kiwifruit slices. Postharvest Biol. Technol. 120, 45–51 (2016). https://doi.org/10.1016/j.postharvbio.2016.05.011

Moradi, M., Tajik, H., Rohani, S.M.R., Oromiehíe, A.R., Malekinejad, H., Aliakbarlu, J.: Hadian, M: Characterization of antioxidant chitosan film incorporated with Zataria multiflora Boiss essential oil and grape seed extract. LWT-Food Sci. Technol. 46(2), 477–484 (2012). https://doi.org/10.1016/j.lwt.2011.11.020

López-Mata, M.A., Ruiz-Cruz, S., Silva-Beltrán, N.P., De Jesús Ornelas-Paz, J., Zamudio-Flores, P.B., Burruel-Ibarra, S.E.: Physicochemical, antimicrobial and antioxidant properties of chitosan films incorporated with carvacrol. Molecules 18(11), 13735–13753 (2013). https://doi.org/10.3390/molecules181113735

Piñeros-Hernández, D., Medina-Jaramillo, C., López-Córdoba, A., Goyanes, S.: Edible cassava starch films carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocolloids 63, 488–495 (2017). https://doi.org/10.1016/j.foodhyd.2016.09.034

García, M.A., Pinotti, A., Martino, M.N., Zaritzky, N.E.: Characterization of starch and composite edible films and coatings. In: Hurber, K.C., Embuscado, M. (eds.) Edible Films and Coatings for Food Applications, pp. 169–209. Springer, New York (2009). https://doi.org/10.1007/978-0-387-92824-1_6

Andrade, R.M.S., Ferreira, S.L.M., Gonçalves, E.C.B.A.: Development and characterization of edible films based on fruit and vegetable residues. J. Food Sci. 81(2), E412–E418 (2016). https://doi.org/10.1111/1750-3841.13192

Romero-Bastida, C.A., Bello-Pérez, L.A., García, M.A., Martino, M.N., Solorza-Feria, J., Zaritzky, N.E.: Physicochemical and microstructural characterization of films prepared by thermal and cold gelatinization from non-conventional sources of starches. Carbohydr. Polym. 60(2), 235–244 (2005). https://doi.org/10.1016/j.carbpol.2005.01.004

Zahedi, Y., Ghanbarzadeh, B., Sedaghat, N.: Physical properties of edible emulsified films based on pistachio globulin protein and fatty acids. J. Food Eng. 100(1), 102–108 (2010). https://doi.org/10.1016/j.jfoodeng.2010.03.033

Kurt, A., Kahyaoglu, T.: Characterization of a new biodegradable edible film made from salep glucomannan. Carbohydr. Polym. 104, 50–58 (2014). https://doi.org/10.1016/j.carbpol.2014.01.003

Saberi, B., Chockchaisawasdee, S., Golding, J.B., Scarlett, C.J., Stathopoulos, C.E.: Physical and mechanical properties of a new edible film made of pea starch and guar gum as affected by glycols, sugars and polyols. Int. J. Biol. Macromol. 104, 345–359 (2017). https://doi.org/10.1016/j.ijbiomac.2017.06.051

Nouraddini, M., Esmaiili, M., Mohtarami, F.: Development and characterization of edible films based on eggplant flour and corn starch. Int. J. Biol. Macromol. 120, 1639–1645 (2018). https://doi.org/10.1016/j.ijbiomac.2018.09.126

Araújo, A., Galvão, A., Silva Filho, C., Mendes, F., Oliveira, M., Barbosa, F., Sousa Filho, M., Bastos, M.: Okra mucilage and corn starch bio-based film to be applied in food. Polym. Test. 71, 352–361 (2018). https://doi.org/10.1016/j.polymertesting.2018.09.010

Silva, O.A., Pellá, M.G., Pellá, M.G., Caetano, J., Simões, M.R., Bittencourt, P.R.S., Dragunski, D.C.: Synthesis and characterization of a low solubility edible film based on native cassava starch. Int. J. Biol. Macromol. 128, 290–296 (2019). https://doi.org/10.1016/j.ijbiomac.2019.01.132

Maniglia, B.C., Tessaro, L., Ramos, A.P., Tapia-Blácido, D.R.: Which plasticizer is suitable for films based on babassu starch isolated by different methods? Food Hydrocolloids 89, 143–152 (2019). https://doi.org/10.1016/j.foodhyd.2018.10.038

Tapia-Blácido, D.R., Maniglia, B.C., Martelli-Tosi, M., Passos, V.F.: Agroindustrial biomass: potential materials for biopolymeric film production. In: Masuelli, M., (ed.) Biopackaging, 1st ed. pp. 226–245, CRC Press, Boca Raton (2017). https://doi.org/10.1201/9781315152349-6

Anchundia, K., Santacruz, S., Coloma, J.: Physical characterization of edible films based on banana peel (Musa paradisiaca). Rev. Chil. Nutr. 43(4), 394–399 (2016). https://doi.org/10.4067/S0717-75182016000400009 (in Spanish)

Cavalcante Fai, A.E., de Souza Alves, M.R., Vinhoso Bruno, N., de Andrade Gonçalves, B.: Production of edible coating based on fruit and vegetable residues: application on minimally processed carrot (Daucus carota L.). Sci. Agropecu. 6(1), 59–68 (2015). https://doi.org/10.17268/sci.agropecu.2015.01.06

Park, S., Zhao, Y.: Development and characterization of edible films from cranberry pomace extracts. J. Food Sci. 71(2), E95–E101 (2006). https://doi.org/10.1111/j.1365-2621.2006.tb08902.x

Guadarrama-Lezama, A.Y., Castaño, J., Velázquez, G., Carrillo-Navas, H., Alvarez-Ramírez, J.: Effect of nopal mucilage addition on physical, barrier and mechanical properties of citric pectin-based films. J. Food Sci. Technol. 55(9), 3739–3748 (2018). https://doi.org/10.1007/s13197-018-3304-x

Gheribi, R., Puchot, L., Verge, P., Jaoued-Grayaa, N., Mezni, M., Habibi, Y., Khwaldia, K.: Development of plasticized edible films from Opuntia ficus-indica mucilage: a comparative study of various polyol plasticizers. Carbohydr. Polym. 190, 204–211 (2018). https://doi.org/10.1016/j.carbpol.2018.02.085

Pérez-Gago, M.B., Krochta, J.M.: Lipid particle size effect on water vapor permeability and mechanical properties of whey protein/beeswax emulsion films. J. Agric. Food Chem. 49(2), 996–1002 (2001). https://doi.org/10.1021/jf000615f

Gómez-Guillén, M.C., Ihl, M., Bifani, V., Silva, A., Montero, P.: Edible films made from tuna-fish gelatin with antioxidant extracts of two different murta ecotypes leaves (Ugni molinae Turcz). Food Hydrocolloids 21(7), 1133–1143 (2007). https://doi.org/10.1016/j.foodhyd.2006.08.006

FAOSTAT. Food and Agriculture Organization of the United Nations. Statistics Division. https://www.fao.org/faostat/es/#data/QC (2007). Accessed 22 August 2019

Arapoglou, D., Varzakas, Th, Vlyssides, A., Israilides, C.: Ethanol production from potato peel waste (PPW). Waste Manag. 30(10), 1898–1902 (2010). https://doi.org/10.1016/j.wasman.2010.04.017

Wu, D.: Recycle technology for potato peel waste processing: a review. Proced. Environ. Sci. 31, 103–107 (2016). https://doi.org/10.1016/j.proenv.2016.02.014

Ncobela, C.N., Kanengoni, A.T., Hlatini, V.A., Thomas, R.S., Chimonyo, M.: A review of the utility of potato by-products as a feed resource for smallholder pig production. Anim. Feed Sci. Technol. 227, 107–117 (2017). https://doi.org/10.1016/j.anifeedsci.2017.02.008

Mora, M.: Mercado, estrategias y limitaciones de comunicación. In: Inglese, P., Jacobo, C.M., Nefzaoui, A., Sáenz, C. (eds.) Ecología del Cultivo, Manejo y Usos del Nopal, pp. 199–206. FAO-ICARDA. Rome, Italy (2018). ISBN:978-92-5-130494-5

Koubaa, M., Ktata, A., Barba, F.J., Grimi, N., Mhemdi, H., Bouaziz, F., Driss, D., Chaabouni, S.E.: Water-soluble polysaccharides from Opuntia stricta Haw. fruit peels: recovery, identification and evaluation of their antioxidant activities. Int. Agrophys. 29(3), 299–306 (2015). https://doi.org/10.1515/intag-2015-0035

Majdoub, H., Roudesli, S., Deratani, A.: Polysaccharides from prickly pear peel and nopals of Opuntia focus-indica: extraction, characterization and polyelectrolyte behaviour. Polym. Int. 50(5), 552–560 (2001). https://doi.org/10.1002/pi.665

Valcárcel-Yamani, B., Rondán-Sanabria, G.G., Finardi-Filho, F.: The physical, chemical and functional characterization of starches from Andean tubers: oca (Oxalis tuberosa Molina), olluco (Ullucus tuberosus Caldas) and mashua (Tropaeolum tuberosum Ruiz & Pavón). Braz. J. Pharm. Sci. 49(3), 453–464 (2013). https://doi.org/10.1590/S1984-82502013000300007

Espino-Díaz, M., De Jesús Ornelas-Paz, J., Martínez-Téllez, M.A., Santillán, C., Barbosa-Cánovas, G.V. Zamudio-Flores, P.B., Olivas G.I.: Development and characterization of edible films based on mucilage of Opuntia ficus-indica (L.). J. Food Sci. 75(6), E347–E352 (2010). https://doi.org/10.1111/j.1750-3841.2010.01661.x

Pelissari, F.M., Andrade-Mahecha, M.M., do Amaral Sobral, P.J., Menegalli, F.C.: Comparative study on the properties of flour and starch films of plantain bananas (Musa paradisiaca). Food Hydrocolloids. 30(2), 681–690 (2013). https://doi.org/10.1016/j.foodhyd.2012.08.007

Gómez-Estaca, J., Giménez, B., Montero, P., Gómez-Guillén, M.C.: Incorporation of antioxidant borage extract into edible films based on sole skin gelatin or a commercial fish gelatin. J. Food Eng. 92(1), 78–85 (2009). https://doi.org/10.1016/j.jfoodeng.2008.10.024

AOAC: Official Methods of Analysis, 18th edn. Association of Official Analytical Chemists, Washington (2005)

Basiak, E., Galus, S., Lenart, A.: Characterization of composite edible films based on wheat starch and whey-protein isolate. Int. J. Food Sci. Technol. 50(2), 372–380 (2015). https://doi.org/10.1111/ijfs.12628

ASTM: ASTM E96-95 Standard Test Methods for Water Vapor Transmission of Materials, pp. 1–8. American Society for Testing and Materials, West Conshohocken (1995)

Gennadios, A., Weller, C.L., Gooding, C.H.: Measurement errors in water vapor permeability of highly permeable, hydrophilic edible films. J. Food Eng. 21(4), 395–409 (1994). https://doi.org/10.1016/0260-8774(94)90062-0

Di Rienzo, J.A., Casanoves, F., Balzarini, M.G., González, L., Tablada, M., Robledo, C.W.: InfoStat version 2011. Universidad Nacional de Córdoba, Argentina, Grupo InfoStat FCA (2011)

Al-Hassan, A.A., Norziah, M.H.: Starch–gelatin edible films: water vapor permeability and mechanical properties as affected by plasticizers. Food Hydrocolloids 26(1), 108–117 (2012). https://doi.org/10.1016/j.foodhyd.2011.04.015

Bastos, M.D.S.R., da Silva Laurentino, L., Canuto, K.M., Mendes, L.G., Martins, C.M., Frota Silva, S.M., Furtado, R.F., Kim, S., Biswas, A., Cheng, H.N.: Physical and mechanical testing of essential oil-embedded cellulose ester films. Polym. Test. 49, 156–161 (2016). https://doi.org/10.1016/j.polymertesting.2015.11.006

Han, J.H., Gennadios, A.: Edible films and coatings: a review. In: Han, J.H. (ed.) Innovations in Food Packaging, pp. 213–255. Academy Press, Oxford (2005). https://doi.org/10.1016/B978-012311632-1/50047-4

Cao, W., Cheng, M., Ao, Q., Gong, Y., Zhao, N., Zhang, X.: Physical, mechanical and degradation properties, and Schwann cell affinity of cross-linked chitosan films. J. Biomater. Sci. 16(6), 791–807 (2005). https://doi.org/10.1163/1568562053992496

Pacheco, N., Naal-Ek, M.G., Ayora-Talavera, T., Shirai, K., Román-Guerrero, A., Fabela-Morón, M.F., Cuevas-Bernardino, J.C.: Effect of bio-chemical chitosan and gallic acid into rheology and physicochemical properties of ternary edible films. Int. J. Biol. Macromol. 125, 149–158 (2019). https://doi.org/10.1016/j.ijbiomac.2018.12.060

Homez-Jara, A., Daza, L.D., Aguirre, D.M., Muñoz, J.A., Solanilla, J.F., Váquiro, H.A.: Characterization of chitosan edible films obtained with various polymer concentrations and drying temperatures. Int. J. Biol. Macromol. 113, 1233–1240 (2018). https://doi.org/10.1016/j.ijbiomac.2018.03.057

Srinivasa, P.C., Ramesh, M.N., Tharanathan, R.N.: Effect of plasticizers and fatty acids on mechanical and permeability characteristics of chitosan films. Food Hydrocolloids 21(7), 1113–1122 (2007). https://doi.org/10.1016/j.foodhyd.2006.08.005

Kowsik, P.V., Mazumder, N.: Structural and chemical characterization of rice and potato starch granules using microscopy and spectroscopy. Microsc. Res. Tech. 81(12), 1533–1540 (2018). https://doi.org/10.1002/jemt.23160

Madera-Santana, T.J., Vargas-Rodríguez, L., Núñez-Colín, C.A., González-García, G., Peña-Caballero, V., Núñez-Gastélum, J.A., Gallegos-Vázquez, C., Rodríguez-Núñez, J.R.: Mucilage from cladodes of Opuntia spinulifera Salm-Dyck: chemical, morphological, structural and thermal characterization. CYTA-J. Food. 16(1), 650–657 (2018). https://doi.org/10.1080/19476337.2018.1454988

Tee, Y.B., Tee, L.T., Daengprok, W., Talib, R.A.: Chemical, physical, and barrier properties of edible film from flaxseed mucilage. BioResources 12(3), 6656–6664 (2017). https://doi.org/10.15376/biores.12.3.6656-6664

Zhang, Y., Han, J.H.: Plasticization of pea starch films with monosaccharides and polyols. J. Food Sci. 71(6), E253–E261 (2006). https://doi.org/10.1111/j.1750-3841.2006.00075.x

Park, J.W., Im, S.S., Kim, S.H., Kim, Y.H.: Biodegradable polymer blends of poly(L-lactic acid) and gelatinized starch. Polym. Eng. Sci. 40(12), 2539–2550 (2000). https://doi.org/10.1002/pen.11384

Cerqueira, M.A., Souza, B.W.S., Teixeira, J.A., Vicente, A.A.: Effect of glycerol and corn oil on physicochemical properties of polysaccharide films—a comparative study. Food Hydrocolloids 27(1), 175–184 (2012). https://doi.org/10.1016/j.foodhyd.2011.07.007

Fox, D.I., Pichler, T., Yeh, D.H., Alcantar, N.A.: Removing heavy metals in water: the interaction of cactus mucilage and arsenate (As (V)). Environ. Sci. Technol. 46(8), 4553–4559 (2012). https://doi.org/10.1021/es2021999

Chen, Y., Zhang, J.G., Sun, H.J., Wei, Z.J.: Pectin from Abelmoschus esculentus: optimization of extraction and rheological properties. Int. J. Biol. Macromol. 70, 498–505 (2014). https://doi.org/10.1016/j.ijbiomac.2014.07.024

Kozarski, M., Klaus, A., Niksic, M., Jakovljevic, D., Helsper, J.P.F.G., Van Griensven, L.J.L.D.: Antioxidative and immunomodulating activities of polysaccharide extracts of the medicinal mushrooms Agaricus bisporus, Agaricus brasiliensis, Ganoderma lucidum and Phellinus linteus. Food Chem. 129(4), 1667–1675 (2011). https://doi.org/10.1016/j.foodchem.2011.06.029

van Soest, J.J.G., Tournois, H., de Wit, D., Vliegenthart, J.F.G.: Short-range structure in (partially) crystalline potato starch determined with attenuated total reflectance Fourier-transform IR spectroscopy. Carbohydr. Res. 279, 201–214 (1995). https://doi.org/10.1016/0008-6215(95)00270-7

Lin, S.Y., Chen, K.S., Run-Chu, L.: Organic esters of plasticizers affecting the water absorption, adhesive property, glass transition temperature and plasticizer permanence of Eudragit acrylic films. J. Controll. Release 68(3), 343–350 (2000). https://doi.org/10.1016/S0168-3659(00)00259-5

Bonilla, J., Atarés, L., Vargas, M., Chiralt, A.: Properties of wheat starch film-forming dispersions and films as affected by chitosan addition. J. Food Eng. 114(3), 303–312 (2013). https://doi.org/10.1016/j.jfoodeng.2012.08.005

Acknowledgements

The authors acknowledge the Vicerrectorado de Investigación of the Universidad Nacional Micaela Bastidas de Apurímac (UNAMBA) for financing the research and diffusion support; and the Escuela Académico Profesional de Ingeniería Agroindustrial of UNAMBA for access to equipment; the participation of the Centro de Investigación y de Estudios Avanzados del IPN CINVESTAV-IPN Unidad Mérida Yucatán, México, Laboratorio Nacional de Nano y Biomateriales (LANNBIO) projets FOMIX-YUCATAN 2008-108160; and CONACYT LAB-2009-01-123913, 188345, 204822. Special thanks to M.C. Dora A. Huerta Quintanilla for technical assistance in the SEM analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ayquipa-Cuellar, E., Salcedo-Sucasaca, L., Azamar-Barrios, J.A. et al. Assessment of Prickly Pear Peel Mucilage and Potato Husk Starch for Edible Films Production for Food Packaging Industries. Waste Biomass Valor 12, 321–331 (2021). https://doi.org/10.1007/s12649-020-00981-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-00981-y