Abstract

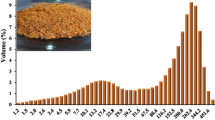

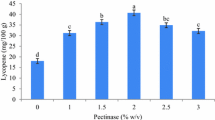

Lycopene is a highly-prized antioxidant with associated health benefits and is abundant in natural sources. A green valorization approach was used to extract lycopene from tomato processing waste. Ultrasound-assisted extraction was applied to the tomato waste using an eco-friendly solvent mixture containing ethyl lactate and ethyl acetate for the extraction of lycopene. Extraction parameters were: X1 = extraction temperature (°C), X2 = proportion of ethyl acetate in solvent mixture (% v/v), X3 = solvent:sample ratio (mL/g), and X4 = extraction time (min). A Box–Behnken design was used to define experimental conditions, and response surface methodology was then conducted to determine the optimized conditions: X1 = 63.4 °C, X2 = 30% (v/v), X3 = 100 mL/g, and X4 = 20 min. The experimental optimized extraction yield of lycopene was 1334.8 µg/g (d.w.), in agreement with the predicted yield. At the same conditions without ultrasound, a yield of 1209.5 µg/g (d.w.) was obtained (9.4% lower). Ultrasound increases extraction yield, and tomato processing by-products are a viable alternative source of extractable lycopene. This represents a greener strategy for the extraction of lycopene in comparison to conventional methods using organic solvents, and shows a promising alternative use for a food processing waste.

Similar content being viewed by others

References

Galanakis, C.M.: Recovery of high added-value components from food wastes: conventional, emerging technologies and commercialized applications. Trends Food Sci. Technol. 26, 68–87 (2012)

Mirabella, N., Castellani, V., Sala, S.: Current options for the valorization of food manufacturing waste: a review. J. Clean Prod. 65, 28–41 (2014)

Rao, A.V., Agarwal, S.: Role of lycopene as antioxidant carotenoid in the prevention of chronic diseases: a review. Nutr. Res. 19(2), 305–323 (1999)

Rodriguez-Amaya, D.B., Kimura, M.: Harvestplus Handbook for Carotenoid Analysis. HarvestPlus Technical Monograph 2. International Food Policy Research Institute (IFPRI) and International Center for Tropical Agriculture (CIAT), Washington, DC (2004)

Singh, P., Goyal, G.K.: Dietary lycopene: its properties and anticarcinogenic effects. Compr. Rev. Food Sci. Food Saf. 7, 255–270 (2008)

Ciriminna, R., Fidalgo, A., Meneguzzo, F., Ilharco, L.M., Pagliaro, M.: Lycopene: emerging production methods and applications of a valued carotenoid. ACS Sustain. Chem. Eng. 4(3), 643–650 (2016)

Arimboor, R., Natarajan, R.B., Menon, K.R., Chandrasekhar, L.P., Moorkoth, V.: Red pepper (Capsicum annuum) carotenoids as a source of natural food colors: analysis and stability—a review. J. Food Sci. Technol. 52(3), 1258–1271 (2015)

Celli, G.B., Teixeira, A.G., Duke, T.G., Brooks, M.S.: Encapsulation of lycopene from watermelon in calcium-alginate microparticles using an optimized inverse-gelation method. Int. J. Food Sci. Technol. 51, 1523–1529 (2016)

Shen, R., Jiang, X., Ye, W., Song, X., Liu, L., Lao, X., Wu, C.: A novel and practical synthetic route for the total synthesis of lycopene. Tetrahedron 67, 5610–5614 (2011)

Rath, S., Olempska-Beer, Z., Kuznesof, P.M.: Lycopene extract from tomato. Chemical and Technical Assessment (CTA). http://www.fao.org/fileadmin/templates/agns/pdf/jecfa/cta/71/lycopene_extract_from_tomato.pdf (2009). Accessed 28 Aug 2017

Sharma, S.K., Le Maguer, M.: Lycopene in tomatoes and tomato pulp fractions. Ital. J. Food Sci. 8(2), 107–113 (1996)

Wang, L., Weller, C.L.: Recent advances in extraction of nutraceuticals from plants. Trends Food Sci. Technol. 17, 300–312 (2006)

FDA (U.S. Food and Drug Administration): Food Additive Status List. U.S. Department of Health and Human Service, Silver Spring, MD. https://www.fda.gov/Food/IngredientsPackagingLabeling/FoodAdditivesIngredients/ucm091048.htm#ftnH (2018). Accessed 07 Apr 2018

ATSDR (Agency for Toxic Substances and Disease Registry): Toxicological profile for n-Hexane. U.S. Department of Health and Human Services, Public Health Service, Atlanta, GA. https://www.atsdr.cdc.gov/toxprofiles/tp113.pdf (1999). Accessed 21 June 2017

Strati, I.F., Oreopoulou, V.: Process optimisation for recovery of carotenoids from tomato waste. Food Chem. 129, 747–752 (2011)

Hartwig, A.: Ethyl acetate. In: The MAK-Collection for Occupational Health and Safety. Part I: MAK Value Documentations. pp. 167–176. Wiley, Hoboken (2012)

WHO (World Health Organization): Evaluations of the Joint FAO/WHO Expert Committee on Food Additives (JECFA). http://apps.who.int/food-additives-contaminants-jecfa-database/chemical.aspx?chemID=2357 (1996). Accessed 07 Apr 2018

Cascant, M.M., Breil, C., Garrigues, S., de la Guardia, M., Fabiano-Tixier, A.S., Chemat, F.: A green analytical chemistry approach for lipid extraction: computation methods in the selection of green solvents as alternative to hexane. Anal. Bioanal. Chem. 409, 3527–3539 (2017)

Calvo, M.M., Dado, D., Santa-Maria, G.: Influence of extraction with ethanol or ethyl acetate on the yield of lycopene, β-carotene, phytoene and phytofluene from tomato peel powder. Eur. Food Res. Technol. 224, 567–571 (2007)

Lavecchia, R., Zuorro, A.: Improved lycopene extraction from tomato peels using cell-wall degrading enzymes. Eur. Food Res. Technol. 228, 153–158 (2008)

Lianfu, Z., Zelong, L.: Optimization and comparison of ultrasound/microwave assisted extraction (UMAE) and ultrasonic assisted extraction (UAE) of lycopene from tomatoes. Ultrason. Sonochem. 15, 731–737 (2008)

Villanueva-Bermejo, D., Reglero, G., Fornari, T.: Recent advances in the processing of green tea biomolecules using ethyl lactate. A review. Trends Food Sci. Technol. 62, 1–12 (2017)

Pereira, C.S.M., Silva, V.M.T.M., Rodrigues, A.E.: Ethyl lactate as a solvent: properties, applications, and production processes—a review. Green Chem. 13, 2658–2671 (2011)

Ishida, B.K., Chapman, M.H.: Carotenoid extraction from plants using a novel, environmentally friendly solvent. J. Agric. Food Chem. 57, 1051–1059 (2009)

Strati, I.F., Oreopoulou, V.: Effect of extraction parameters on the carotenoid recovery from tomato waste. Int. J. Food Sci. Technol. 46, 23–29 (2011)

Strati, I.F., Gogou, E., Oreopoulou, V.: Enzyme and high pressure assisted extraction of carotenoids from tomato waste. Food Bioprod. Process. 94, 668–674 (2015)

Strati, I.F., Oreopoulou, V.: Recovery and isomerization of carotenoids from tomato processing by-products. Waste Biomass Valoriz. 7(4), 843–850 (2016)

Chemat, F., Rombaut, N., Sicaire, A., Meullemiestre, A., Fabiano-Tixier, A., Abert-Vian, M.: Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason. Sonochem. 34, 540–560 (2017)

Vilkhu, K., Mawson, R., Simons, L., Bates, D.: Applications and opportunities for ultrasound assisted extraction in the food industry—a review. Innov. Food Sci. Emerg. 9, 161–169 (2008)

Suslick, K.S.: Sonochemistry. Science 247(4949), 1439–1445 (1990)

Zardo, I., Sobczyk, A.E., Marczak, L.D.F., Sarkis, J.: Optimization of ultrasound assisted extraction of phenolic compounds from sunflower seed cake using response surface methodology. Waste Biomass Valoriz. (2017). https://doi.org/10.1007/s12649-017-0038-3

Deng, G., Xu, D., Li, S., Li, H.: Optimization of ultrasound-assisted extraction of natural antioxidants from sugar apple (Annona squamosa L.) peel using response surface methodology. Molecules 20, 448–459 (2015)

Londoño-Londoño, J., Lima, V.R., Lara, O., Gil, A., Pasa, T.B.C., Arango, G.J., Pineda, J.R.R.: Clean recovery of antioxidant flavonoids from citrus peel: optimizing an aqueous ultrasound-assisted extraction method. Food Chem. 119, 81–87 (2010)

Eh, A.L., Teoh, S.: Novel modified ultrasonication technique for the extraction of lycopene from tomatoes. Ultrason. Sonochem. 19, 151–159 (2012)

Ahmadi, M., Heidari, O., Nafchi, A.R.M.: Optimization of lycopene extraction from tomato waste with the integration of ultrasonic—enzymatic processes by response surface methodology. J. Ind. Eng. Res. 1(2), 29–34 (2015)

Konwarh, R., Pramanik, S., Kalita, D., Mahanta, C.L., Karak, N.: Ultrasonication—a complementary ‘green chemistry’ tool to biocatalysis: a laboratory-scale study of lycopene extraction. Ultrason. Sonochem. 19, 292–299 (2012)

Kumcuoglu, S., Yilmaz, T., Tavman, S.: Ultrasound assisted extraction of lycopene from tomato processing wastes. J. Food Sci. Technol. 51(12), 4102–4107 (2014)

AOAC (Association of Official Analytical Chemists): Method 934.06: Moisture in Dried Fruits. Official Methods of Analysis of the AOAC International, 18 edn. AOAC International, Gaithersburg (2005)

Kaur, D., Wani, A.A., Oberoi, D.P.S., Sogi, D.S.: Effect of extraction conditions on lycopene extractions from tomato processing waste skin using response surface methodology. Food Chem. 108, 711–718 (2008)

Box, G.E., Hunter, J.S., Hunter, W.G.: Statistics for Experimenters: Design, Innovation, and Discovery, 2 edn. Wiley, Hoboken (2005)

NIST/SEMATECH: NIST/SEMATECH e-Handbook of Statistical Methods. 5. Process Improvement. http://www.itl.nist.gov/div898/handbook/pri/pri.htm (2012). Accessed 05 Apr 2017

Silva, Y.P.A., Pereira, V.A., Brooks, M.S., Ferreira, T.A.P.C.: Effect of solvent on lycopene extraction yield from tomato pomace. Paper presented at the CSBE/SCGAB Annual General Meeting and Technical Conference joint with CIGR VI Technical Symposium, Winnipeg, Canada. http://www.csbe-scgab.ca/publications/meeting-papers/csbe-technical-conferences/8072 (2017). Accessed 25 Aug 2017

Zang, L., Sommerburg, O., Van Kuijk, F.J.G.M.: Absorbance changes of carotenoids in different solvents. Free Radic. Biol. Med. 23(7), 1086–1089 (1997)

Tonucci, L.H., Holden, J.M., Beecher, G.R., Khachik, F., Davis, C.S., Mulokozi, G.: Carotenoid content of thermally processed tomato-based food products. J. Agric. Food Chem. 43(3), 579–586 (1995)

Gama, J.T., Tadiotti, A.C., Sylos, C.M.: Comparison of carotenoid content in tomato, tomato pulp and ketchup by liquid chromatography. Aliment. Nutr. 17(4), 353–358 (2006)

Periago, M.J.S., Rincón, F., Agüera, M.D., Ros, G.: Mixture approach for optimizing lycopene extraction from tomato and tomato products. J. Agric. Food Chem. 52, 5796–5802 (2004)

Lundstedt, T., Seifert, E., Abramo, L., Thelin, B., Nyström, Å, Pettersen, J., Bergman, R.: Experimental design and optimization. Chemom. Intell. Lab. 42(1), 3–40 (1998)

Brittton, G.: UV/visible spectroscopy. In: Britton, G., Liaaen-Jensen, S., Pfander, H. (eds.) Carotenoids. Volume 1B: Spectroscopy, pp. 13–62. Birhäuser Verlag, Basel (1995)

Takehara, M., Nishimura, M., Kuwa, T., Inoue, Y., Kitamura, C., Kumagai, T., Honda, M.: Characterization and thermal isomerization of (all-E)lycopene. J. Agric. Food Chem. 62, 264–269 (2014)

Berger, P.D., Maurer, R.E., Celli, G.B.: Experimental Design with Applications in Management, Engineering, and the Sciences, 2 edn. Springer, Cham (2018)

Henry, L.K., Catignani, G.L., Schwartz, S.J.: Oxidative degradation kinetics of lycopene, lutein, and 9-cis and all-trans β-carotene. J. Am. Oil Chem. Soc. 75(7), 823–829 (1998)

Lee, M.T., Chen, B.H.: Stability of lycopene during heating and illumination in a model system. Food Chem. 78, 425–432 (2002)

Palma, M., Barbero, G.F., Piñero, Z., Liazid, A., Barroso, C.G., Rostagno, M.A., Prado, J.M., Meireles, M.A.A.: Extraction of natural products: principles and fundamental aspects. In: Rostagno, M. A., Prado, J. M. (eds.) Natural Product Extraction: Principles and Applications, pp. 58–88. The Royal Society of Chemistry, Cambridge (2013)

Strati, I.F., Oreopoulou, V.I.: Recovery of carotenoids from tomato processing by-products—a review. Food Res. Int. 65, 311–321 (2014)

Sala, S., Anton, A., McLaren, S.J., Notarnicola, B., Saouter, E., Sonesson, U.: In quest of reducing the environmental impacts of food production and consumption. J. Clean Prod. 140, 387–398 (2017)

Toma, M., Vinatoru, M., Paniwnyk, L., Mason, T.J.: Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrason. Sonochem. 8(2), 137–142 (2001)

Acknowledgements

The authors would like to thank the processing company who provided the tomato pomace for this study and are grateful to Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (Coordination for the Improvement of Higher Education Personnel) (CAPES—Brazil), the Department of Foreign Affairs, Trade and Development (DFATD—Canada), and the Natural Sciences and Engineering Research Council (NSERC—Canada) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Silva, Y.P.A., Ferreira, T.A.P.C., Celli, G.B. et al. Optimization of Lycopene Extraction from Tomato Processing Waste Using an Eco-Friendly Ethyl Lactate–Ethyl Acetate Solvent: A Green Valorization Approach. Waste Biomass Valor 10, 2851–2861 (2019). https://doi.org/10.1007/s12649-018-0317-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-018-0317-7