Abstract

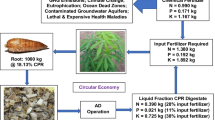

Due to the progressive increase of organic solid waste generation worldwide and the awareness of its potential negative impacts on human health and the environment, there is a need for developing sustainable techniques for valorization of organic waste. This paper addresses this challenge. The paper describes the results of three experiments (T1, T2, and T3) to produce a plant-based liquid solution, called liquid organic fertilizer (LOF), through three successive cycles (C1, C2 and C3) of anaerobic digestion and bio-leaching of grass clipping waste in pilot-scale bioreactors. The study investigated the effects of organic load (defined as the mass of total solids in the organic input [grass and molasses] divided by the total input mass [grass, molasses and water]) and the use of liquid molasses as co-digestion element (in T3) on the total nitrogen (TN), total phosphorus (TP) and potassium (K) accumulation in the leachate and the efficiency of nutrient recovery from grass clipping waste with the proposed technology. The organic loads considered were 7.0, 11.2, and 22.4% in T1, T2, and T3, respectively. The use of greater organic load in T2 led to significantly higher or comparable concentrations of TN–TP–K nutrients in the leachate at the end of each production cycle compared to T1. Co-digestion of grass clippings with molasses in test T3 showed a greater nutrient recovery from the grass substrate (RE = 53, 89, 97% for total Kjeldahl N, TP, K respectively) compared to T1 and T2. However, molasses contributes to the input nutrient content and, therefore, the net TN, TP, and K amounts should be also considered when evaluating the efficiency of the production process.

Graphical Abstract

Similar content being viewed by others

References

United States Environmental Protection Agency (US EPA): Advancing Sustainable Materials Management: 2013 Fact Sheet, Assessing Trends in Material Generation, Recycling and Disposal in the United States. US EPA Solid Waste and Emergency Response (5306P), Washington, DC. https://www.epa.gov/sites/production/files/2015-09/documents/2013_ advncng_smm_fs.pdf (2015). Accessed 5 Feb 2017

US EPA: Solid Waste Management and Greenhouse Gases: A Life-Cycle Assessment of Emissions and Sinks, 3rd Ed., p. 140. https://nepis.epa.gov (2006). Accessed 5 Feb 2017

Yoshida, H., Gable, J.J., Park, J.K.: Evaluation of organic waste diversion alternatives for greenhouse gas reduction. Resour. Conserv. Recycl. 60(1), 1–9 (2012)

Van Haaren, R., Themelis, N., Goldstein, N.: The State of Garbage in America. 17th Nationwide Survey of MSW Management in the U.S. Bio-Cycle, Emmaus (2010)

Bidlingmaier, W.: Odour emissions from composting plants. In: de Bertoldi, M., Sequi, P., Lemmes, B., Papi, T. (eds.) The Science of Composting, pp. 71–80. Springer (1996)

Pagans, E., Barrena, R., Font, X., Sanchez, A.: Ammonia emissions from the composting of different organic wastes. Dependency on process temperature. Chemosphere. 62(1), 1534–1542 (2006). doi:10.1016/j.chemosphere.2005.06.044

Sánchez, A., Artola, A., Front, X., Gea, T., Barrena, R., Gabriel, D., Sanchez-Monedero, M.A., Roig, A., Cayuela, M.L., Mondini, C.: Chap. 2–Greenhouse gas from organic waste composting: emissions and measurement. In: Lichtfouse, E., Schwarzbauer, J., Robert, D. (eds.) CO2 Sequestration, Biofuels and Depollution. Springer (2015)

De Keulenaere, B., Laub, K., Michels, E., Van Poucke, R., Boeve, W., Depuydt, T., Trapp, M., Bolzonella, D., Ryckaert, B., Bamelis, L., Hamelin, L., Meers, E.: Good Practice Guide for Grass Valorisation: Recommendations for Biogas Plant Owners and Operators. GR3 Project Report. http://www.grassgreenresource.eu/sites/default/files/IEE_GR3_manual_grass _biogas%20owners_operators_0.pdf (2016). Accessed 5 Feb 2017

Hubbe, M.A., Nazhad, M., Sánchez, C.: Composting as a way to convert cellulosic biomass and organic waste into high-value soil amendments: A review. BioResources 5(4), 2808–2854 (2010)

Sikora, L.J.: Effect of compost-fertilizer blends on crop growth. In: de Bertoldi, M., Sequi, P., Lemmes, B., Papi, T. (eds.) The Science of Composting, pp. 423–430. Springer (1996)

Brown, S., Subler, S.: Composting and greenhouse gas emissions: A producer’s perspective. BioCycle 48(3), p. 37. https://www.biocycle.net/2007/03/23/composting-and-greenhouse-gas-emissions-a-producers-perspective/ (2007). Accessed 26 February 2017

Organic Trade Association (OTA). 2016 State of Organic Industry Fact Sheet. https://www.ota.com/resources/market-analysis (2016). Accessed 22 Nov 2016

Fertilizers Europe. Harvesting Energy with Fertilizers. http://www.fertilizerseurope.com/ media/publications/ (2014). Accessed 5 Feb 2017

Hitaj, C., Suttles, S.: Trends in U.S. Agriculture’s Consumption and Production of Energy: Renewable Power, Shale Energy, and Cellulosic Biomass. Economic Information Bulletin No. 159. U.S. Department of Agriculture, Economic Research Service https://www.ers.usda.gov/webdocs/publications/eib159/60128_eib159.pdf (2016). Accessed 5 Feb 2017

Worrell, E., Phylipsen, D., Einstein, D., Martin, N.: Energy Use and Energy Intensity of the U.S. Chemical Industry.Lawrence Berkeley National Laboratory. http://escholarship.org/ uc/item/2925w8g6 (2000). Accessed 5 Feb 2017

Gellings, C.W., Parmenter, K.E.: Energy efficiency in fertilizer production and use. In: Gellings, C.W., Blok, K., eds., Efficient Use and Conservation of Energy and Use. In Encyclopedia of Life Support Systems (EOLSS), developed under the auspices of the UNESCO, EOLSS Publishers, Oxford. http://www.eolss.net (2004). Accessed 5 Feb 2017

Adekunle, K.F., Okolie, J.A.: A review of biochemical process of anaerobic digestion. Adv. Biosci. Biotechnol. 6(1), 205–212 (2015). doi:10.4236/abb.2015.63020

Samani, Z., Bandini, P.: Valorization of agricultural residuals through biophysical transformation into an organic soil enhancer. Abstract 367. 251st ACS National Conference, San Diego, California. https://ep70.eventpilotadmin.com/web/page.php?page=IntHtml& project = ACS16spring&id = 2394787(2016). Accessed 5 Feb 2017

El-Mashad, H.M., Zhang, R.: Biogas production from co-digestion of dairy manure and food waste. Bioresour. Tech. 101(1), 4021–4028 (2010). doi:10.1016/j.biortech.2010.01.027

Khalid, A., Arshad, M., Anjum, M., Mahmood, T., Dawson, L.: The anaerobic digestion of solid organic waste. Waste Manag. (Oxford). 31(8), 1737–1744 (2011). doi:10.1016/j.wasman.2011.03.021

Misi, S.N., Forster, C.F.: Batch co-digestion of multiple-component agro-wastes. Bioresourc. Technol. 80(1), 19–28 (2001). doi:10.1016/S0960-8524(01)00078-5

Sarker, S., Moller, H.B.: Regulating feeding and increasing methane yield from co-digestion of C5 molasses and cattle manure. Energy Convers. Manag. 84, 7–12 (2014). doi:10.1016/j.enconman.2014.03.082

De Vrieze, J., Plovie, K., Verstraete, W., Boon, N.: Co-digestion of molasses or kitchen waste with high-rate activated sludge results in a diverse microbial community with stable methane production. J. Environ. Manag. 152, 75–82 (2015). doi:10.1016/j.jenvman.2015.01.029

Voca, N., Kricka, T., Cosic, T., Rupic, V., Jukic, Z., Kalambura, S.: Digested residue as a fertilizer after the mesophilic process of anaerobic digestion. Plant Soil Environ. 51(6), 262–266 (2005)

Huez-Lopez, M.A.: Comparative Responses to Inorganic and Organic Fertilization of Chile Pepper Plants Grown under Saline Conditions. Ph.D. Dissertation, Plant and Environmental Sciences, New Mexico State University, Las Cruces, New Mexico (2007)

Huez-Lopez, M.A., Ulery, A.L., Samani, Z., Picchioni, G., Flynn, R.P.: Response of chile pepper (Capsicum annuum L.) to salt stress and organic and inorganic nitrogen sources: I. Growth and yield. Trop Subtrop Agroecosystems 14, 137–147 (2011)

Huez-Lopez, M.A., Ulery, A.L., Samani, Z., Picchioni, G., Flynn, R.P.: Response of chile pepper (Capsicum annuum L.) to salt stress and organic and inorganic nitrogen sources: II. Nitrogen and water use efficiencies, and salt tolerance. Trop. Subtrop. Agroecosystems 14, 757–763 (2011)

Huez-Lopez, M.A., Ulery, A.L., Samani, Z., Picchioni, G., Flynn, R.P.: Response of chile pepper (Capsicum annuum L.) to salt stress and organic and inorganic nitrogen sources: III. Ion uptake and translocation. Trop. Subtrop. Agroecosystems 14, 765–776 (2011)

Niemela, S.I., Sivela, C., Luoma, T., Tuovinen, O.H.: Maximum temperature limits for acidophilic, mesophilic bacteria in biological leaching systems. Appl. Environ. Microbiol. 60(9), 3444–3446 (1994)

Kardos, L., Juhasz, A., Palko, G., Olah, J., Barkacs, K., Zaeay, G.: Comparing of mesophilic and thermophilic anaerobic fermented sewage sludge based on chemical and biochemical tests. Appl. Ecol. Environ. Res. 9(3), 293–302 (2011). doi: 10.15666/aeer

Kurchania, A.K.: Biomass energy. In: Biomass Conversion: The Interface of Biotechnology, Chemistry and Materials Science, Baskar, C., Baskar, S., Dhillon, R.S. (eds.) Springer (2012). doi:10.1007/978-3-642-28418-2

Kroeker, E.J., Schulte, D.D., Sparling, A.B., Lapp, H.M.: Anaerobic treatment process stability. J. Water Pollut. Control Fed. 51(1), 718–727 (1979)

Hach Company: Total Nitrogen, Persulfate Digestion Method 10072. DOC316.53.01085, 11th Ed., Loveland, Colorado https://www.hach.com/asset-get.download.jsa?id=7639983803 (2015) Accessed 4 July 2017

Hach Company: Total Phosphorus, Molybdovanadate with Acid Persulfate Digestion Method 10127. DOC316.53.01123, 9th Ed., Loveland, Colorado https://www.hach.com/asset-get.download.jsa?id=7639983840 (2014) Accessed 4 July 2017

Hach Company: Potassium, Tetraphenylborate Method 8049. DOC316.53.01127, 8th Ed., Loveland, Colorado https://www.hach.com/asset-get.download.jsa?id=7639983843 (2014) Accessed 4 July 2017

Gavlak, R., Horneck, D., Miller, R.: Plant, Soil and Water Reference Methods for the Western Region, 3rd Ed., Western Region Extension Publications (WREP) 125. http://www.naptprogram.org/files/napt/western-states-method-manual-2005.pdf (2005). Accessed 5 Feb 2017

United States Environmental Protection Agency (US EPA) Staff: Inductively Coupled Plasma Atomic Emission Spectrometric Method for Trace Element Analysis of Water and Wastes. USEPA Method 2007, U.S. Government Print Office, Washington (1982)

Merlin Christy, P., Gopinath, L.R., Divya, D.: A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renew. Sustain. Energy Rev. 34, 167–173 (2014). doi:10.1016/j.rser.2014.03.010

Pan, G., Smith, P., Pan, W.: The role of soil organic matter in maintaining the productivity and yield stability of cereals in China. Agric. Ecosyst. Environ. 129, 344–348 (2009). doi:10.1016/j.agee.2008.10.008

Thomas, M., Wright, P., Blackall, L., Urbain, V., Keller, J.: Optimization of Noosa BNR plant to improve performance and reduce operating costs. Water Sci. Technol. 47(12), 141–148 (2003)

Oehmen, A., Lemos, P.C., Carvalho, G., Yuan, Z., Keller, J., Blackall, L.L., Reis, M.A.: Advances in enhanced biological phosphorus removal: from micro to macro scale. Water Res. 41(11), 2271–2300 (2007). doi:10.1016/j.watres.2007.02.030

Tong, J., Chen, Y.: Enhanced biological phosphorus removal driven by short-chain fatty acids produced from waste activated sludge alkaline fermentation. Environ. Sci. Technol. 41, 7126–7130 (2007). doi:10.1021/es071002n

Acknowledgements

This material is based upon work primarily supported by the National Science Foundation (NSF) under NSF Award Number EEC-1449501. Any opinions, findings and conclusions, or recommendations expressed in this material are those of the authors, and do not necessarily reflect those of the NSF. The technology described in this paper is protected by U.S. Patent 11, 866, 827. The authors thank Victor Lara and Jason Alcantar, undergraduate research students at New Mexico State University (NMSU), and Andrea Quitugua and Jose Martinez, student participants of the Research Experience for Undergraduates (REU) program at NMSU, for their assistance with testing setup and data collection. The authors sincerely thank the NMSU golf course staff that collected the grass clippings used in the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mostafazadeh-Fard, S., Samani, Z. & Bandini, P. Production of Liquid Organic Fertilizer Through Anaerobic Digestion of Grass Clippings. Waste Biomass Valor 10, 771–781 (2019). https://doi.org/10.1007/s12649-017-0095-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0095-7