Abstract

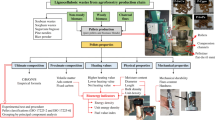

Brazil has a highlighted position in comparison to other countries in relation to the amount of renewable raw materials, as the lignocellulosic wastes, and technologies for production of alternative energy. The aim of the study was to evaluate the potential of lignocellulosic wastes such as: from soybean culture, sugarcane bagasse and eucalyptus wood for pellets production focusing the generation of heat energy, and classify them according to the commercialization standards. The properties as heating value, bulk density, energetic density and proximate analysis of the biomasses were evaluated. The pellets were produced with diameter of 6 mm in a horizontal planar array pelletizer. The raw material used generated pellets with eucalyptus and soybean wastes mixed in different proportions, as well was done for sugarcane bagasse and soybean wastes. These mixtures were compared to pellets composed by 100% soybean wastes, 100% sugarcane bagasse and commercial pellets produced with pine wood. The pellets were evaluated through the physical properties (moisture, bulk density and unitary density), energetic properties (heating value and energetic density), chemical properties (volatiles, fixed carbon and ash) and mechanical properties (hardness and mechanical durability). Among the pellets produced, the 100% sugarcane bagasse highlighted by high values for mechanical durability (96.64%), hardness (39.46 kgf) and energetic densities, besides low production of fines (0.18%). Pellets composed by the tested mixtures obtained higher values for heating value, mechanical durability, hardness and lower fines and ashes content in comparison to the pellets composed only by soybean wastes. The increasing of eucalyptus sawdust percentage in the pellets decreased their ashes content in comparison to the 100% soybean wastes (from 26.72 to 14.03%). The sugarcane bagasse pellets showed similar properties to the commercial ones.

Similar content being viewed by others

References

Aragón-Garita, S., Moya, R., Bond, B., Valaert, J., Filho, M.T.: Production and quality analysis of pellets manufactured from five potential energy crops in the Northern Region of Costa Rica. Biomass Bioenergy 87, 84–95 (2016)

ASTM D 1762-84.: American Society for Testing Materials—Standard Method for Chemical Analyses of Wood Charcoal. ASTM International, Philadelphia (2007)

ASTM E711-87.: American Society For Testing Materials—Standard Test Method for Gross Calorific Value of Refuse-Derived Fuel by the Bomb Calorimeter. ASTM International, Philadelphia (2004)

Brand, M.A.: Forest Biomass Energy. Interciência, Rio de Janeiro (2010)

Carroll, J.P., Finnan, J.: Physical and chemical properties of pellets from energy crops and cereal straws. Biosystems Eng. 112, 151–159 (2012)

Castellano, J.M., Gómez, M., Fernández, M., Esteban, L.S., Carrasco, J.E.: Study on the effects of raw materials composition and pelletization conditions on the quality and properties of pellets obtained from different woody and non woody biomasses. Fuel 139, 629–636 (2015)

Choi, H.L., Sudiarto, S.I.A., Renggaman, A.: Prediction of livestock manure and mixture higher heating value based on fundamental analysis. Fuel 116, 772–780 (2014)

Conab.: Companhia Nacional De Abastecimento—Follow-up of the Brazilian sugarcane crop. Conab, Brasília (2015)

Dias, J.M.C.S., Souza, D.T., Braga, M.: Production of briquettes and pellets from agricultural, agroindustrial and forestry wastes. Embrapa Agroenergia, Brasília (2012)

DIN EN 14774-1.: Deutsches Institut Für Normung—Determination of Moisture Content—Oven Dry Method—Part 1: Total moisture—Reference Method. DIN EN 14774-1, Berlin (2010)

DIN EN 14961-2.: Deutsches Institut Für Normung—Solid biofuels: Fuel specifications and classes – Part 2: Wood pellets for non-industrial use. DIN EN 14961-2, Berlin (2011)

DIN EN 14961-6.: Deutsches Institut Für Normung—Solid biofuels: Fuel specifications and classes—Part 6: Non-Woody Pellets for Non-Industrial Use. DIN EN 14961-6, Berlin (2012)

DIN EN 15103.: Deutsches Institut Für Normung—Determination of bulk density. DIN EN 15103, Berlin (2010)

DIN EN 15210-1.: Deutsches Institut Für Normung—Solid biofuels—Determination of mechanical durability of pellets and briquettes—Part 1: Pellets. DIN EN 15210-1, Berlin (2010)

Duca, D., Riva, G., Foppa Pedretti, E., Toscano, G.: Wood pellet quality with respect to EN 14961-2 standard and certifications. Fuel 135, 9–14 (2014)

EPE.: Empresa De Pesquisa Energética—National Energetic Balance: Base 2013. EPE, Rio de Janeiro (2014)

Faria, W.S., Protásio, T.P., Trugilho, P.F., Pereira, B.L.C., Carneiro, A.C.O., Andrade, C.R., Guimarães Junior, J.B.: Transformation of lignocellulosic waste of coffee into pellets for thermal power generation. Coffee. Sci. 11, 137–147 (2016)

Garcia, D.P., Caraschi, J.C., Ventorim, G.: Energetic characterization of wood pellets. Rev. Madeira 135, 14–18 (2013)

García-Maraver, A., Popov, V., Zamorano, M.: A review of European standards for pellet quality. Renew. Energy 36, 3537–3540 (2011)

García-Maraver, A., Rodriguez, M.L., Serrano-Bernardo, F., Diaz, L.F., Zamorano, M.: Factors affecting the quality of pellets made from residual biomass of olive trees. Fuel Process. Technol. 129, 1–7 (2015)

Garcia, D.P., Caraschi, J.C., Ventorim, G.: The wood pellets sector in Brazil. Ciência da Madeira 8, 21–28 (2017)

García, R., Pizarro, C., Lavín, A. G., Bueno, J. L.: Biomass proximate analysis using thermogravimetry. Bioresour. Technol. 139, 1–4 (2013)

Gil, M.V.P., Oulego, M.D., Casal, C., Pevida, C., Pis, J.J., Rubiera, F.: Mechanical durability and combustion characteristics of pellets from biomass blends. Bioresour. Technol. 101, 8859–8867 (2010)

Ishii, K., Furuichi, T.: Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets. Waste Manag. 34, 2621–2626 (2014)

Jenkins, B., Baxter, L., Miles, J.R.: Combustion properties of biomass. Fuel Process. Technol. 54, 17–46 (1998)

Lehtikangas, P.: Quality properties of pelletised sawdust, logging residues and bark. Biomass Bioenergy 20, 351–360 (2001)

Liu, Z., Liu, X., Fei, B., Jiang, Z., Cai, Z., Yua, Y.: The properties of pellets from mixing bamboo and rice straw. Renew. Energy 55, 1–5 (2013)

Liu, Z., Mi, B., Jiang, Z., Fei, B., Cai, Z., Liu, X.: Improved bulk density of bamboo pellets as biomass for energy production. Renew. Energy 86, 1–7 (2016)

Liu, Z.G., Quek, A., Balasubramanian, R.: Preparation and characterization of fuel pellets from woody biomass, agro-residues and their corresponding hydrochars. Appl. Energy 113, 1315–1322 (2014)

Lora, E.E.S., Ayarza, J.A.C.: Gasification. Biomass for Energy. Campinas-SP: Unicamp 241–327 (2008)

Madadian, E., Akbarzadeh, A.H., Lefsrud, M.: Pelletized composite wood fiber mixed with plastic as advanced solid biofuels: thermo-chemical analysis. Waste Biomass Valor. 8, 1–15 (2017)

Mahapatra, A.K., Harris, D.L., Durham, D.L., Lucas, S., Terril, T.H., Kouakou, B., Kannan, G.: Effect of moisture change on the physical and thermal properties of Sericea lespedeza pellets. Int. Agr. Eng. J. 19, 23–29 (2010)

Mani, S., Tabil, L.G., Sokhansanj, S.: Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 30, 648–654 (2006)

Moreno-Lopez, M., Alarcón-Herrera, M.T., Martin-Dominguez, I.R.: Feasibility of pelletizing forest residues in Northern Mexico. Waste Biomass Valor. 8, 923–932 (2017)

Moya, R., Rodríguez-Zúñiga, A., Tenorio, C., Valdez, J., Valaert, J.: Pellets evaluation made from tropical-climate agricultural and forestry crops of Costa Rica with a domestic stove. Waste Biomass. Valor. 6, 1037–1046 (2015)

Nhuchhen, D.R., Salam, P.A.: Estimation of higher heating value of biomass from proximate analysis: A new approach. Fuel 99, 55–63 (2012)

Niedziółka, I., Szpryngiel, M., Kachel-Jakubowska, M., Kraszkiewicz, A., Zawiślak, K., Sobczak, P., Nadulski, R.: Assessment of the energetic and mechanical properties of pellets produced from agricultural biomass. Renew. Energy 76, 312–317 (2015)

Nunes, L.J.R., Matias, J.C.O., Catalao, J.P.S.: Mixed biomass pellets for thermal energy production: A review of combustion models. Appl. Energy 127, 135–140 (2014)

Obernberger, I., Thek, G.: The pellet Handbook: The Production and Thermal Utilisation of Pellets. Earthscan, London (2010)

Paula, L.E.R., Trugilho, P.F., Napoli, A., Bianchi, M.L.: Characterization of residues from plant biomass for use in energy generation. Cerne 17, 237–246 (2011)

Peng, J., Wang, J.I.: Effects of thermal treatment on energy density and hardness of torrefied wood pellets. Fuel Process. Technol. 119, 168–173 (2015)

Pereira, B.L.C., Carneiro, A.C.O., Carvalho, A.M.L., Vital, B.R., Oliveira, A.C., Canal, W.D.: Influence of adding kraft lignin in eucalyptus pellets properties. Floresta 46, 235–242 (2016)

Protásio, T.P., Alves, I.C.N., Trugilho, P.F., Silva, V.O., Baliza, A.E.R.B.: Compaction of plant biomass for solid biofuels production. Pesqui. Florestal Bras. 31, 273–283 (2011)

Protásio, T.P., Neves, T.A., Reis, A.A., Trugilho, P.F.: Effect of age and clone on the quality of Eucalyptus spp wood aiming bioenergy production. Ciência Florestal 24, 465–477 (2014)

Richards, S.R.: Physical testing of fuel briquettes. Fuel Process. Technol. 25, 89–100 (1990)

Said, N., Abdel Daiem, M.M., García-Maraver, A., Zamorano, M.: Influence of densification parameters on quality properties of rice straw pellets. Fuel Process. Technol. 138, 56–64 (2015)

Said, N., Abdel Daiem, M.M., García-Maraver, A., Zamorano, M.: Reduction of ash sintering precursor components in rice straw by water washing. Bioresources 9, 6756–6764 (2014)

Spanhol, A., Nones, D.L., Kumabe, F.J.B., Brand, M.A.: Quality of forest biomass pellets produced in State of Santa Catarina for power generation. Floresta. 45, 833–844 (2015)

Stasiak, M., Molenda, M., Bańda, M., Wiącek, J., Parafiniuk, P., Gondek, E.: Mechanical and combustion properties of sawdust—straw pellets blended in different proportions. Fuel Process. Technol. 156, 366–375 (2017)

Stelte, W., Holm, J.K., Sanadi, A.R., Barsberg, S., Ahrenfeldt, J., Henriksen, U.B.: Fuel pellets from biomass: the importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 90, 3285–3290 (2011)

Theerarattananoon, K., Xu, F., Wilson, J., Ballard, R., Mckinney, L., Staggenborg, S., Vadlani, P., Pei, Z.J., Wang, D.: Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crop. Prod. 33, 325–332 (2011)

Tumuluru, J.S.: Effect of process variables on the density and durability of the pellets made from high moisture corn stover. Biosyst. Eng. 119, 44–57 (2014)

Vale, A.T., Brasil, M.A.M., Leão, A.L.: Energetic quantification and characterization of wood and bark of species of “cerrado. Ciência Florestal 12, 71–80 (2002)

Wang, S., Yuan, X., Li, C., Huang, Z., Leng, L., Zeng, G., Li, H.: Variation in the physical properties of wood pellets and emission of aldehyde/ketone under different storage conditions. Fuel 183, 314–321 (2016)

Yin, C.Y.: Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 90, 1128–1132 (2011)

Zamorano, M., Popov, V., Rodríguez, M.L., García-Maraver, A.: A comparative study of quality properties of pelletized agricultural and forestry lopping residues. Renew. Energy 36, 3133–3140 (2011)

Acknowledgements

The authors thank to Fundação de Amparo à Pesquisa do Estado de Minas Gerais—FAPEMIG, Fundação de Amparo à Pesquisa do Estado de Goiás—FAPEG, Coordenacão de Aperfeiçoamento de Pessoa de Nível Superior—CAPES. Conselho Nacional de Desenvolvimento Científico e Tecnológico—CNPq, Brazilian Research Network in Lignocellulosic Composites and Nanocomposites—RELIGAR.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scatolino, M.V., Neto, L.F.C., Protásio, T.d.P. et al. Options for Generation of Sustainable Energy: Production of Pellets Based on Combinations Between Lignocellulosic Biomasses. Waste Biomass Valor 9, 479–489 (2018). https://doi.org/10.1007/s12649-017-0010-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0010-2