Abstract

Purpose

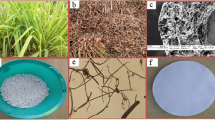

This investigation is aimed to explore the pulp and papermaking potential of solid residue left after isolation of essential oil from Cymbopogon winterianus Jowitt using hydro distillation, as well as to evaluate the physical strength properties of pulp and paper produced from it.

Methods

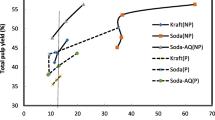

Soda, soda–AQ (soda–anthraquinone) and kraft pulping of oil isolated C. winterianus were optimized and the corresponding optimum unbleached pulp in each process was subjected to environment friendly ECF (elemental chlorine free) bleaching using D1EpD2 (D = chlorine dioxide in acidic medium; Ep = alkaline extraction with addition of hydrogen peroxide; 1 and 2 = first and second time) sequence. Fibre morphological investigation and fibre classification of bleached pulp from every optimized pulping process were also carried out. Hand sheets of bleached pulps were prepared to evaluate the physical strength properties. All the methods were followed as per standard procedures.

Results

The proximate chemical composition of oil isolated C. winterianus revealed 62.70% holocellulose, 37.62% alpha-cellulose, 21.10% pentosans and 24.10% lignin. Kraft pulping at 12% NaOH dose and 20% sulphidity produced unbleached pulp with kappa 18.72, yield 43.68%, brightness 21.36% and viscosity 32.6 cp; while bleached pulp with brightness 83.67% and viscosity 16.7 cp. However, hand sheets prepared from soda–AQ pulping exhibited tensile index 31.5 N m/g, tear index 5.02 m Nm2/g and burst index 2.20 kPam2/g which were superior to kraft pulping. Soda pulp demonstrated inferiority in quality to kraft and soda–AQ pulps. No significant differences were observed in fibre morphology of pulps from different processes while fibre classification revealed maximum useful bleached fibres 55.9% from kraft pulping.

Conclusions

This research proved that C. winterianus solid residue left after isolation of essential oil could be a substantial source for pulp and papermaking using conventional pulping processes and ECF bleaching sequence at process conditions described in this work.

Similar content being viewed by others

References

Rodríguez, A., Moral, A., Serrano, L., Labidi, J., Jiménez, L.: Rice straw pulp obtained by using various methods. Bioresour. Technol. 99, 2881–2886 (2008)

Worland, J.: Here’s how many trees humans cut down each year. time.com/4019277/trees-humans-deforestation/ (2015). Accessed 23 Aug 2016

Kamoga, O.L.M., Kirabira, J.B., Byaruhanga, J.K.: The potential of Cymbopogon nardus in the production of pulp for paper industry. International Conference on Computing, Mechanical and Electronics Engineering, Singapore, 9–10, July 2015

Rao, B.R.R: Biomass yield and essential oil yield variations in Java Citronella (Cymbopogan winteranius Jowitt.), intercropped with food legumes and vegetables. J. Agron. Crop Sci. 185, 99–103 (2000)

Kakaraparthi, P.S., Srinivas, K.V.N.S., Kumar, J.K., Kumara, A.N., Rajput, D.K., Sarma, V.U.M.: Variation in the essential oil content and composition of Citronella (Cymbopogon winterianus Jowitt.) in relation to time of harvest and weather conditions. Ind. Crop. Prod. 61, 240–248 (2014)

Kaur, H., Dutt, D., Tyagi, C.H.: Optimization of soda pulping process of lignocellulosic residues of Lemon and Sofia grasses produced after steam distillation. Bioresources 6, 103–120 (2010)

Deka, H., Deka, S., Baruah, C.K., Das, J., Hoque, S., Sarma, N.S.: Vermicomposting of distillation waste of Citronella plant (Cymbopogon winterianus Jowitt.) employing Eudrilus eugeniae. Bioresour. Technol. 102, 6944–6950 (2011)

Blank, A.F., Costa, A.G., Blank, M.F. A., Cavalcanti, S.C.H., Alves, P.B., Innecco, R., Ehlert, P.A.D., Sousa, I.F.: Influence of season, harvest time and drying on Java citronella (Cymbopogon winterianus Jowitt) volatile oil. Braz. J. Pharmacog. 17, 557–564 (2007)

Kaur, H., Dutt, D.: Anatomical, morphological and chemical characterization of lignocellulosic by-products of Lemon and Sofia grasses obtained after recuperation of essential oils by steam distillation. Cellul. Chem. Technol. 47, 83–94 (2013)

Dutt, D., Garg, A.P., Tyagi, C.H., Upadhyay, A.K.: Bio-alkaper and peroxide-alkali delihnification of solid waste of Cymbopogon martini with Phanerochaeta chrysosporium. Indian J. Chem. Tech. 14, 229–239 (2007)

Anupam, K., Lal, P.S., Bist, V., Sharma, A.K., Swaroop, V.: Raw material selection for pulping and papermaking using TOPSIS multiple criteria decision making design. Environ. Prog. Sustain. Energy. 33, 1034–1041 (2014)

Anupam, K., Swaroop, V., Sharma, A.K., Lal, P.S., Bist, V.: Sustainable raw material selection for pulp and paper using SAW multiple criteria decision making design. IPPTA J. 1, 67–76 (2015)

Katiyar, R., Gupta, S., Yadav K.R.: Cymbopogon winterianus: An important species for essential java citronella oil and medicinal value. Proceeding of National Conference on Forest Biodiversity : Earth’s Living Treasure 115–118 (2011)

Wise, L.E., Murphy, M., D’Addieco, A.A.: Chlorite holocellulose, its fraction and bearing on summative wood analysis and studies on the hemicelluloses. Pap. Trade J. 22, 34–44 (1946)

Gominho, J., Lourenco, A., Curt, M., Ferna’ndez, J., Pereira, H.: Characterization of hairs and pappi from Cynara cardunculus capitula and their suitability for paper production. Ind. Crops Prod. 29, 116–125 (2009)

Ferhi, F., Satyajit, D., Elaloui, E., Moussaoui, Y., Yanez, J.G.: Chemical characterisation and suitability for papermaking applications studied on four species naturally growing in Tunisia. Ind. Crops Prod. 61, 180–185 (2014)

Bhardwaj, N.K., Goyal, S.K., Gupta, A., Upadhyaya, J.S., Ray, A.K.: Soda and Soda-anthraquinone pulping of rice straw. APPITA J. 58, 180–185 (2005)

Dutt, D., Upadhyaya, J.S.: Studies on alkoxygen and alkoxygen anthraquinone delignification of Ipomea-carnea. Res. Ind. 39, 202–208 (1994)

Rolf, B., Christina, J., Lars-Åke, L., Yngve, L.: Non-wood pulping technology present status and future. IPPTA J. 21, 115–120 (2009)

Sharma, A.K., Anupam, K., Swaroop, V., Lal, P.S., Bist, V.: Pilot scale soda-anthraquinone pulping of palm oil empty fruit bunches and elemental chlorine free bleaching of resulting pulp. J. Clean. Prod. 106, 422–429 (2015)

http://www.dcpulppaper.org/gifs/report28.pdf. Accessed 15 May 2016

Wang, H.H.: Cellulose and pulp. In: Owens, J.N., Lund, H.G. (eds.) Forests and forest plants-Volume II, pp. 158–178. Encyclopaedia of Life Support Systems Publishers, United Kingdom (2009)

Kamoga, O.L.M., Kirabira, J.B., Byaruhanga, J.K., Godiyal, R.D., Anupam, K.: Characterisation and evaluation of pulp and paper from selected Ugandan grasses for paper industry. Cellul. Chem. Technol. 50, 275–284 (2016)

http://www.dcpulppaper.org/gifs/report24.pdf. Accessed 15 May 2016

Ramazani, O., Latibari, A.J., Faezipour, M., Enayati, A.A., Alajdad, M.S.M.M.: Investigation on the influence of paper making variables on apparent density of paper produced from old corrugated container Iran. J. Wood Pap. Sci. Res. 22, 1–17 (2007)

https://research.cnr.ncsu.edu/wpsanalytical/documents/56Tensile.doc. Accessed 15 May 2016

https://research.cnr.ncsu.edu/wpsanalytical/documents/55Tearing.doc. Accessed 15 May 2016

Hassan, N.H.M., Muhammed, S., Ibrahim, R.: Effect of soda-anthraquinone pulping conditions and beating revolution on the mechanical properties of paper made from Gigantochloa scortechinii (Semantan Bamboo). Malays. J. Anal. Sci. 17, 75–84 (2013)

http://billerudkorsnas.se/Documents/49711130_handbok_E2_2_120425.pdf. Accessed 15 May 2016

Acknowledgements

Authors would like to acknowledge Dr. Nirpendra Chauhan, Scientist-In-Charge, Centre for Aromatic Plants, Industrial Estate, Selaqui 248197, Dehradun, India for arranging hydro distillation waste of C. winterianus Jowitt. We also thank Dr. Priti Shivhare Lal-Scientist EI, Dr. Sanjay Tyagi-Scientist C, Dr. Arvind Kumar Sharma-Sr. Scientific Assistant and Mr. Vinay Swaroop-Junior Research Fellow at Central Pulp and Paper Research Institute, Himmat Nagar, Saharanpur 247001, Uttar Pradesh, India for their valuable insight and support during execution of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, N., Godiyal, R.D., Bhawana et al. Pulping and Bleaching of Hydro Distillation Waste of Citronella Grass (Cymbopogon winterianus Jowitt) for Papermaking. Waste Biomass Valor 9, 409–419 (2018). https://doi.org/10.1007/s12649-016-9791-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9791-y