Abstract

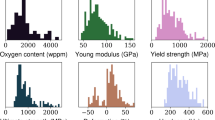

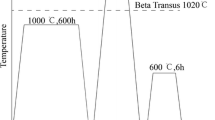

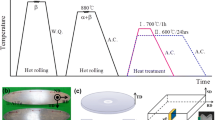

The high-throughput diffusion-multiple technique and thermodynamics databases were used to design new high-strength Ti alloys. The composition–microstructure–property relationships of the Ti64–xMo alloys were obtained. The phase fraction and composition of the α and β phases of the Ti64–xMo alloys were calculated using the Thermo-Calc software. After aging at 600°C, the Ti64–6Mo alloy precipitated ultrafine α phases. This phenomenon was explained on the basis of the pseudo-spinodal mechanism by calculating the Gibbs energy curves of the α and β phases of the Ti64–xMo alloys at 600°C. Bulk forged Ti64–6Mo alloy exhibited high strength and moderate plasticity after α/β-phase-field solution treatment plus aging. The tensile properties of the alloy were determined by the size and morphology of the primary and secondary α phases and by the β grain size.

Similar content being viewed by others

Change history

14 January 2020

The original version of this article unfortunately contained a mistake.

References

H.X. Li, X.Y. Nie, Z.B. He, K.N. Zhao, Q. Du, J.S. Zhang, and L.Z. Zhuang, Interfacial microstructure and mechanical properties of Ti–6Al–4V/Al7050 joints fabricated using the insert molding method, Int. J. Miner. Metall. Mater., 24(2017), No. 12, p. 1412.

M.K. Ibrahim, E. Hamzah, S.N. Saud, E.N.E. Abu Bakar, and A. Bahador, Microwave sintering effects on the microstructure and mechanical properties of Ti–51at% Ni shape memory alloys, Int. J. Miner. Metall. Mater., 24(2017), No. 3, p. 280.

R.R. Boyer, An overview on the use of titanium in the aerospace industry, Mater. Sci. Eng. A, 213(1996), No. 1–2, p. 103.

T.N. Prasanthi, C. Sudha, and S. Saroja, Effect of alloying elements on interdiffusion phenomena in explosive clads of 304LSS/Ti–5Ta–2Nb alloy, J. Mater. Sci., 51(2016), No. 11, p. 5290.

H.P. Duan, H.X. Xu, W.H. Su, Y.B. Ke, Z.Q. Liu, and H.H. Song, Effect of oxygen on the microstructure and mechanical properties of Ti–23Nb–0.7Ta–2Zr alloy, Int. J. Miner. Metall. Mater., 19(2012), No. 12, p. 1128.

S.L. Semiatin, P.N. Fagin, M.G. Glavicic, I.M. Sukonnik, and O.M. Ivasishin, Influence on texture on beta grain growth during continuous annealing of Ti–6Al–4V, Mater. Sci. Eng. A, 299(2001), No. 1–2, p. 225.

Y.J. Lai, S.W. Xin, P.X. Zhang, Y.Q. Zhao, F.J. Ma, X.H. Liu, and Y. Feng, Recrystallization behavior of Ti40 burn-resistant titanium alloy during hot working process, Int. J. Miner. Metall. Mater., 23(2016), No. 5, p. 581.

T. Seshacharyulu, S.C. Medeiros, J.T. Morgan, J.C. Malas, W.G. Frazier, and Y.V.R.K. Prasad, Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V, Mater. Sci. Eng. A, 279(2000), No. 1–2, p. 289.

A. Nocivin, I. Cinca, D. Raducanu, V.D. Cojocaru, and I.A. Popovici, Mechanical properties of a Gum-type Ti–Nb–Zr–Fe–O alloy, Int. J. Miner. Metall. Mater., 24(2017), No. 8, p. 909.

S. Raghunathan, R.J. Dashwood, M. Jackson, S.C. Vogel, and D. Dye, The evolution of microtexture and macrotexture during subtransus forging of Ti–10V–2Fe–3Al, Mater. Sci. Eng. A, 488(2008), No. 1–2, p. 8.

G.T. Terlinde, T.W. Duerig, and J.C. Williams, Microstructure, tensile deformation, and fracture in aged ti 10V–2Fe–3Al, Metall. Trans. A, 14(1983), No. 10, p. 2101.

B. He, X.J. Tian, X. Cheng, J. Li, and H.M. Wang, Effect of weld repair on microstructure and mechanical properties of laser additive manufactured Ti-55511 alloy, Mater. Des., 119(2017), p. 437.

S. Nag, R. Banerjee, J.Y. Hwang, M. Harper, and H.L. Fraser, Elemental partitioning between α and β phases in the Ti–5Al–5Mo–5V–3Cr–0.5Fe (Ti-5553) alloy, Philos. Mag., 89(2009), No. 6, p. 535.

F.W. Chen, G.L. Xu, X.Y. Zhang, K.C. Zhou, and Y.W. Cui, Effect of α morphology on the diffusional β↔α transformation in Ti-55531 during continuous heating: Dissection by dilatometer test, microstructure observation and calculation, J. Alloys Compd., 702(2017), No. 25, p. 352.

J.K. Fan, J.S. Li, H.C. Kou, K. Hua, and B. Tang, The interrelationship of fracture toughness and microstructure in a new near β titanium alloy Ti–7Mo–3Nb–3Cr–3Al, Mater. Charact., 96(2014), p. 93.

B. Cherukuri, R. Srinivasan, S. Tamirisakandala, and D.B. Miracle, The influence of trace boron addition on grain growth kinetics of the beta phase in the beta titanium alloy Ti–15Mo–2.6Nb–3Al–0.2Si, Scripta Mater., 60(2009), No. 7, p. 496.

N.G. Jones, R.J. Dashwood, M. Jackson, and D. Dye, Development of chevron-shaped α precipitates in Ti–5Al–5Mo–5V–3Cr, Scripta Mater., 60(2009), No. 7, p. 571.

A. Dehghan-Manshadi and R.J. Dippenaar, Development of α-phase morphologies during low temperature isothermal heat treatment of a Ti–5Al–5Mo–5V–3Cr alloy, Mater. Sci. Eng. A, 528(2011), No. 3, p 1833.

J.K. Fan, H.C. Kou, M.J. Lai, B. Tang, H. Chang, and J.S. Li, Characterization of hot deformation behavior of a new near beta titanium alloy: Ti-7333, Mater. Des., 49(2013), p. 945.

J.I. Qazi, H.J. Rack, and B. Marquardt, High-strength metastable beta-titanium alloys for biomedical applications, JOM, 56(2004), No. 11, p. 49.

R. Banerjee, S. Nag, J. Stechschulte, and H.L. Fraser, Strengthening mechanisms in Ti–Nb–Zr–Ta and Ti–Mo–Zr–Fe orthopaedic alloys, Biomaterials, 25(2004), No. 17, p. 3413.

T. Zhou, M. Aindow, S.P. Alpay, M.J. Blackburn, and M.H. Wu, Pseudo-elastic deformation behavior in a Ti/Mo-based alloy, Scripta Mater., 50(2004), No. 3, p. 343.

T. Oyama, C. Watanabe, and R. Monzen, Growth kinetics of ellipsoidal ω-precipitates in a Ti–20 wt%Mo alloy under compressive stress, J. Mater. Sci., 51(2016), No. 19, p. 8880.

C.H. Wang, C.D. Yang, M. Liu, X. Li, P.F. Hu, A.M. Russell, and G.H. Cao, Martensitic microstructures and mechanical properties of as-quenched metastable β-type Ti–Mo alloys, J. Mater. Sci., 51(2016), No. 14, p. 6886.

R. Monzen, R. Kawai, T. Oyama, and C. Watanabe, Tensile-stress-induced growth of ellipsoidal ω-precipitates in a Ti–20wt%Mo Alloy, J. Mater. Sci., 51(2016), No. 5, p. 2490.

J.C. Zhao, A combinatorial approach for efficient mapping of phase diagrams and properties, J. Mater. Res., 16(2001), No. 6, p. 1565.

J.C. Zhao, X. Zheng, and D.G. Cahill, High-throughput diffusion multiples, Mater. Today, 8(2005), No. 10, p. 28.

J.C. Zhao, X. Zheng, and D.G. Cahill, High-throughput measurements of materials properties, JOM, 63(2011), No. 3, p. 40.

X. Zheng, D.G. Cahill, P. Krasnochtchekov, R.S. Averback, and J.C. Zhao, High-throughput thermal conductivity measurements of nickel solid solutions and the applicability of the Wiedemann-Franz law, Acta Mater., 55(2007), No. 15, p. 5177.

X.D. Zhang, L.B. Liu, J.C. Zhao, J.L. Wang, F. Zheng, and Z.P. Jin, High-efficiency combinatorial approach as an effective tool for accelerating metallic biomaterials research and discovery, Mater. Sci. Eng. C, 39(2014), No. 1, p. 273.

D. Wu, L.B. Liu, L.G. Zhang, L.J. Zeng, and X. Shi, Investigation of the influence of Cr on the microstructure and properties of Ti6Al4VxCr alloys with a combinatorial approach, J. Mater. Eng. Perform., 26(2017), No. 9, p. 4364.

C. Wang, N. Li, Y. Cui, and M.T. Pérez-Prado, Effect of solutes on the rate sensitivity in Ti–xAl–yMo–zV and Ti–xAl–yMo–zCr β–Ti alloys, Scripta Mater., 149(2018), p. 129.

J.C. Williams and B.S. Hickman, Tempering behavior of orthorhombic martensite in titanium alloys, Metall. Mater. Trans. B, 1(1970), No. 9, p. 2648.

H.Y. Kim, Y. Ikehara, J.I. Kim, H. Hosoda, and S. Miyazaki, Martensitic transformation, shape memory effect and superelasticity of Ti–Nb binary alloys, Acta Mater., 54(2006), No. 9, p. 2419.

W.F. Ho, S.C. Wu, S.K. Hsu, Y.C. Li, and H.C. Hsu, Effects of molybdenum content on the structure and mechanical properties of as-cast Ti–10Zr-based alloys for biomedical applications, Mater. Sci. Eng. C, 32(2012), No. 3, p. 517.

W.F. Ho, S.C. Wu, H.H. Chang, and H.C. Hsu, Structure and mechanical properties of Ti–5Cr based alloy with Mo addition, Mater. Sci. Eng. C, 30(2010), No. 6, p. 904.

Z. Du, S. Xiao, L. Xu, J. Tian, F. Kong, and Y. Chen, Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy, Mater. Des., 55(2014), No. 55, p. 183.

W.F. Ho, C.P. Ju, and J.H. Lin, Structure and properties of cast binary Ti–Mo alloys, Biomaterials, 20(1999), No. 22, p. 2115.

Y. Ni and A.G. Khachaturyan, From chessboard tweed to chessboard nanowire structure during pseudospinodal decomposition, Nat. Mater., 8(2009), No. 5, p. 410.

N.T.C. Oliveira and A.C. Guastaldi, Electrochemical stability and corrosion resistance of Ti–Mo alloys for biomedical applications, Acta Biomater., 5(2009), No. 1, p. 399.

S.K. Kar, A. Ghosh, N. Fulzele, and A. Bhattacharjee, Quantitative microstructural characterization of a near beta Ti alloy, Ti-5553 under different processing conditions, Mater. Charact., 81(2013), No. 4, p. 37.

C.Y. Wang, L.W. Yang, Y.W. Cui, and M.T. Pérez-Prado, High throughput analysis of solute effects on the mechanical behavior and slip activity of beta titanium alloys, Mater. Des., 137(2017), p. 371.

L. Mora, C. Quesne, C. Haut, C. Servant, and R. Penelle, Relationships among thermomechanical treatments, microstructure, and tensile properties of a near beta-titanium alloy: β-CEZ: Part I. relationships between thermomechanical treatments and microstructure, J. Mater. Res., 11(1996), No. 1, p. 89.

G. Srinivasu, Y. Natraj, A. Bhattacharjee, T.K. Nandy, and G.V.S.N. Rao, Tensile and fracture toughness of high strength β titanium alloy, Ti–10V–2Fe–3Al, as a function of rolling and solution treatment temperatures, Mater. Des., 47(2013), p. 323.

J. Huang, Z. Wang, and K. Xue, Cyclic deformation response and micromechanisms of Ti alloy Ti–5Al–5V–5Mo–3Cr–0.5Fe, Mater. Sci. Eng. A, 528(2011), No. 29–30, p. 8723.

M. Jackson, N.G. Jones, D. Dye, and R.J. Dashwood, Effect of initial microstructure on plastic flow behaviour during isothermal forging of Ti–10V–2Fe–3Al, Mater. Sci. Eng. A, 501(2009), No. 1–2, p. 248.

D. Qin, Y. Lu, D. Guo, L. Zheng, Q. Liu, and L. Zhou, Tensile deformation and fracture of Ti–5Al–5V–5Mo–3Cr–1.5Zr–0.5Fe alloy at room temperature, Mater. Sci. Eng. A, 587(2013), p. 100.

W.F. Ho, S.C. Wu, S.K. Hsu, Y.C. Li, and H.C. Hsu, Effects of molybdenum content on the structure and mechanical properties of as-cast Ti–10Zr-based alloys for biomedical applications, Mater. Sci. Eng. C, 32(2012), No. 3, p. 517.

Acknowledgements

The authors acknowledge financial support from the National Key Technologies R&D Program of China (Grant No. 2016YFB0701301 and 2018YFB0704100), National Natural Science Foundation of China (Grant No. 51671218 and 51501229), National Key Basic Research Program of China (973 Program) (Grant No. 2014CB644000) and State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wu, D., Wang, Wl., Zhang, Lg. et al. New high-strength Ti–Al–V–Mo alloy: from high-throughput composition design to mechanical properties. Int J Miner Metall Mater 26, 1151–1165 (2019). https://doi.org/10.1007/s12613-019-1854-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1854-1