Abstract

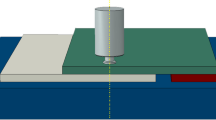

A hybrid joint with a satisfactory mixture of pure magnesium and polypropylene (PP) was achieved via friction stir joining (FSW) in a lap-joint configuration. The tool rotational and travel speeds used in this work were 500–700 r/min and 50–100 mm/min, respectively. The mechanical properties and microstructural analysis of the resultant hybrid Mg/PP joint were examined. The results show that the maximum tensile shear strength (22.5 MPa) of the joint was attained at 700 r/min and 75 mm/min due to the optimum percentage fraction of mechanical interlocking (48%) and the presence of magnesium oxide. The interfacial joint center exhibits the maximum microhardness values because of the presence of refined and intertwined Mg fragments and density dislocations in the matrix of the PP. The joint failed via two different modes: interfacial line and weld zone fractures, respectively.

Similar content being viewed by others

References

P. Kah, R. Suoranta, J. Martikainen, and C. Magnus, Techniques for joining dissimilar materials: Metals and polymers, Rev. Adv. Mater. Sci., 36(2014), p. 152.

Y.X. Huang, X.C. Meng, Y.H. Wang, Y.M. Xie, and L. Zhou, Joining of aluminum alloy and polymer via friction stir lap welding, J. Mater. Process. Technol., 257(2018), p. 148.

K. Nagatsuka, S. Yoshida, A. Tsuchiya, and K. Nakata, Direct joining of carbon-fiber-reinforced plastic to an aluminum alloy using friction lap joining, Composites Part B, 73(2015), p. 82.

R.S. Mishra and Z.Y. Ma, Friction stir welding and processing, Mater. Sci. Eng. R, 50(2005), No. 1–2, p. 1.

R. Nandan, T. Debroy, and H.K.D.H. Bhadeshia, Recent advances in friction-stir welding — Process, weldment structure and properties, Prog. Mater. Sci., 53(2008), No. 6, p. 980.

M. Paidar, O.O. Ojo, A. Moghanian, A.S. Karapuzha, and A. Heidarzadeh, Modified friction stir clinching with protuberance-keyhole levelling: A process for production of welds with high strength, J. Manuf. Processes, 41(2019), p. 177.

H.K. Pabandi, H.R. Jashnani, and M. Paidar, Effect of precipitation hardening heat treatment on mechanical and microstructure features of dissimilar friction stir welded AA2024-T6 and AA6061-T6 alloys, J. Manuf. Processes, 31(2018), p. 214.

B. Heinz and B. Skrotzki, Characterization of a friction-stir-welded aluminum alloy 6013, Metall. Mater. Trans. B, 33(2002), No. 3, p. 489.

A.C. Somasekharan and L.E. Murr, Characterization of complex, solid-state flow and mixing in the friction-stir welding (FSW) of aluminum alloy 6061-T6 to magnesium alloy AZ91D using color metallography, J. Mater. Sci., 41(2006), No. 16, p. 5365.

J.A. Schneider and A.C. Nunes Jr., Characterization of plastic flow and resulting microtextures in a friction stir weld, Metall. Mater. Trans. B, 35(2004), No. 4, p. 777.

Z. Kiss and T. Czigány, Microscopic analysis of the morphology of seams in friction stir welded polypropylene, eXPRESS Polym. Lett., 6(2012), No. 1, p. 54.

M. Elyasi and H.A. Derazkola, Experimental and thermo-mechanical study on FSW of PMMA polymer T-joint, Int. J. Adv. Manuf Technol., 97(2018), No. 1–4, p. 1445.

H. A. Derazkola and A. Simchi, An investigation on the dissimilar friction stir welding of T-joints between AA5754 aluminum alloy and poly(methyl methacrylate), Thin Walled Struct., 135(2019), p. 376.

J.Y. Sheikh-Ahmad, D. S. Ali, S. Deveci, F. Almaskari, and F. Jarrar, Friction stir welding of high density polyethylene-Carbon black composite, J. Mater. Process. Technol., 264(2019), p. 402.

S. Aliasghari, P. Skeldon, X. Zhou, and M. Ghorbani, Influence of PEO and mechanical keying on the strength of AA 5052 alloy/polypropylene friction stir spot welded joints, Int. J. Adhes. Adhes., 92(2019), p. 65.

F. Lambiase, A. Paoletti, V. Grossi, and A. Di Ilio, Analysis of loads, temperatures and welds morphology in FSW of polycarbonate, J. Mater. Process. Technol., 266(2019), p. 639.

S.T. Amancio-Filho, C. Bueno, J.F. dos Santos, N. Huber, and E. Hage Jr., On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures, Mater. Sci. Eng. A, 528(2011), No. 10–11, p. 3841.

X. Cao, Q.Y. Shi, D.M. Liu, Z.L. Feng, Q. Liu, and G.Q. Chen, Fabrication of in situ carbon fiber/aluminum composites via friction stir processing: Evaluation of microstructural, mechanical and tribological behaviors, Composites Part B, 139(2018), p. 97.

H. Shahmiri, M. Movahedi, and A.H. Kokabi, Friction stir lap joining of aluminium alloy to polypropylene sheets, Sci. Technol. Weld. Joining, 22(2017), No. 2, p. 120.

H.A. Derazkola and A. Simchi, Experimental and thermo-mechanical analysis of the effect of tool pin profile on the friction stir welding of poly (methyl methacrylate) sheets, J. Manuf. Processes, 34(2018), p. 412.

M.R. Hajideh, M. Farahani, S.A.D. Alavi, and N.M. Ramezani, Investigation on the effects of tool geometry on the microstructure and the mechanical properties of dissimilar friction stir welded polyethylene and polypropylene sheets, J. Manuf. Processes, 26(2017), p. 269.

H.A. Derazkola, R.K. Fard, and F. Khodabakhshi, Effects of processing parameters on the characteristics of dissimilar friction-stir-welded joints between AA5058 aluminum alloy and PMMA polymer, Weld. World, 62(2018), No. 1, p. 117.

H.A. Derazkola, F. Khodabakhshi, and A. Simchi, Friction-stir lap-joining of aluminum-magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study, Sci. Technol Weld. Joining, 23(2018), No. 1, p. 35.

F. Lambiase, A. Paoletti, V. Grossi, and S. Genna, Improving energy efficiency in friction assisted joining of metals and polymers, J. Mater. Process. Technol., 250(2017), p. 379.

F. Yusof, Y. Miyashita, N. Seo, Y. Mutoh, and R. Moshvan, Utilising friction spot joining for dissimilar joint between aluminium alloy (A5052) and polyethylene terephthalate, Sci. Technol. Weld. Joining, 17(2012), No. 7, p. 544.

H.A. Derazkola and M. Elyasi, The influence of process parameters in friction stir welding of Al-Mg alloy and polycarbonate, J. Manuf. Processes, 35(2018), p. 88.

F. Khodabakhshi, M. Haghshenas, S. Sahraeinejad, J. Chen, B. Shalchi, J. Li, and A.P. Gerlich, Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high-density polyethylene, Mater. Charact., 98(2014), p. 73.

A.R. Patel, D.J. Kotadiya, J.M. Kapopara, C.G. Dalwadi, N.P. Patel, and H.G. Rana, Investigation of mechanical properties for hybrid joint of aluminium to polymer using friction stir welding (FSW), Mater. Today: Proc., 5(2018), No. 2, p. 4242.

M.R. Nakhaei, G. Naderi, and A. Mostafapour, Effect of processing parameters on morphology and tensile properties of PP/EPDM/organoclay nanocomposites fabricated by friction stir processing, Iran. Polym. J., 25(2016), No. 2, p. 179.

A.R. Patel, C.G. Dalwadi, and H.G. Rana, A Review: dissimilar material joining of metal to polymer using friction stir welding (FSW), Int. J. Sci. Technol. Eng., 2(2016), No. 10, p. 702.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moghanian, A., Paidar, M., Seyedafghahi, S.S. et al. Friction stir welding of pure magnesium and polypropylene in a lap-joint configuration: Microstructure and mechanical properties. Int J Miner Metall Mater 26, 766–774 (2019). https://doi.org/10.1007/s12613-019-1784-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1784-y