Abstract

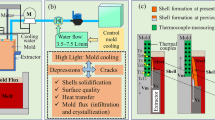

For the control of surface defects in interstitial-free (IF) steel, quantitative metallographic analyses of near-surface inclusions and surface liquid flow detection via the nail-board tipping method were conducted. The results show that, at casting speeds of 0.8 and 1.0 m/min, a thin liquid mold flux layer forms and non-uniform floating of argon bubbles occurs, inducing the entrainment and subsequent entrapment of the liquid flux; fine inclusion particles of Al2O3 can also aggregate at the solidification front. At higher casting speeds of 1.4 and 1.6 m/min, the liquid mold flux can be entrained and carried deeper into the liquid steel pool because of strong level fluctuations of the liquid steel and the flux. The optimal casting speed is approximately 1.2 m/min, with the most favorable surface flow status and, correspondingly, the lowest number of inclusions near the slab surface.

Similar content being viewed by others

References

M. Takahashi, Sheet steel technology for the last 100 years: Progress in sheet steels in hand with the automotive industry, ISIJ Int., 55(2015), No. 1, p. 79.

T. EMI, Steelmaking technology for the last 100 years: toward highly efficient mass production systems for high quality steels, ISIJ Int., 55(2015), No. 1, p. 36.

H.X. Yu, C.X. Ji, B. Chen, C. Wang, and Y.H. Zhang, Characteristics and evolution of inclusion induced surface defects of cold rolled IF sheet, J. Iron Steel Res. Int., 22(2015), Suppl. 1, p. 17.

B.G. Thomas, Review on modeling and simulation of continuous casting, Steel Res. Int., 89(2018), No. 1, art. No. 1700312.

M. Iguchi, J. Yoshida, T. Shimizu, and Y. Mizuno, Model study on the entrapment of mold powder into molten steel, ISIJ Int., 40(2000), No. 7, p. 685.

B.G. Thomas, Modeling of the continuous casting of steel—past, present, and future, Metall. Mater. Trans., B, 33(2002), No. 6, p. 795.

X.X. Deng, L.P. Li, X.H. Wang, Y.Q. Ji, C.X. Ji, and G.S. Zhu, Subsurface macro-inclusions and solidified hook character in aluminum-killed deep-drawing steel slabs, Int. J. Miner. Metall. Mater., 21(2014), No. 6, p. 531.

M.M. Jaradeh and T. Carlberg, Analysis of distribution of nonmetallic inclusions in aluminum DC-cast billets and slabs, Metall. Mater. Trans. B, 43(2012), No. 1, p. 82.

R. Liu, J Sengupta, D. Crosbie, S. Chung, M. Trinh, and B.G. Thomas, Measurement of molten steel surface velocity with SVC and nail dipping during continuous casting process, [in] Symposium on Sensors, Sampling, and Simulation for Process Control Held during the 140th TMS Annual Meeting and Exhibition, San Diego, 2011, p. 51.

S.M. Cho, S.H. Kim, and B.G. Thomas, Transient fluid flow during steady continuous casting of steel slabs: part i. measurements and modeling of two-phase flow, ISIJ Int., 54(2014), No. 4, p. 845.

H.Q. Yu, M.Y. Zhu, and J. Wang, Interfacial fluctuation behavior of steel/slag in medium-thin slab continuous casting mold with argon gas injection, J. Iron Steel Res. Int., 17(2010), No. 4, p. 5.

Y.B. Yin, J.M. Zhang, S.W. Lei, and Q.P. Dong, Numerical study on the capture of large inclusion in slab continuous casting with the effect of in-mold electromagnetic stirring, ISIJ Int., 57(2017), No. 12, p. 2165.

B.G. Thomas, Q. Yuan, S. Mahmood, R. Liu, and R. Chaudhary, Transport and entrapment of particles in steel continuous casting, Metall. Mater. Trans. B, 45(2014), No. 1, p. 22.

X.P. Song, S.S. Cheng, and Z.J. Cheng, Numerical computation for metallurgical behavior of primary inclusion in compact strip production mold, ISIJ Int., 52(2012), No. 10, p. 1824.

C.P. Nie, X.F. Zhang, B. Wang, Y.H. Sun, and Q. Liu, Characteristics of inclusion motion and accumulation in CSP mold, ISIJ Int., 55(2015), No. 8, p. 1677.

S.M. Cho, H.J. Lee, S.H. Kim, R. Chaudhary, B.G. Thomas, D.H. Lee, Y.J. Kim, W.R. Choi, S.K. Kim, and H.S. Kim, Measurement of transient meniscus flow in steel continuous casters and effect of electromagnetic braking, [in] Symposium on Sensors, Sampling, and Simulation for Process Control Held during the 140th TMS Annual Meeting and Exhibition, San Diego, 2011, p. 59.

A.V. Karasev and H. Suito, Characteristics of fine oxide particles produced by Ti/M (M=Mg and Zr) complex deoxidation in Fe-10mass%Ni alloy, ISIJ Int., 48(2008), No. 11, p. 1507.

D.Y. Wang, M.F. Jiang, H. Matsuura, and F. Tsukihashi, Dynamic evolution of inclusions in Ti-bearing Al-deoxidized molten irons at 1873 K, Steel Res. Int., 85(2014), No. 1, p. 16.

H.Q. Yu and M.Y. Zhu, Numerical simulation of the effects of electromagnetic brake and argon gas injection on the three-dimensional multiphase flow and heat transfer in slab continuous casting mold, ISIJ Int., 48(2008), No. 5, p. 584.

N. Kubo, T. Ishii, J. Kubota, and N. Aramaki, Two-phase flow numerical simulation of molten steel and argon gas in a continuous casting mold, ISIJ Int., 42(2002), No. 11, p. 1251.

R. Chaudhary, G.G. Lee, B.G. Thomas, and S.H. Kim, Transient mold fluid flow with well- and mountain-bottom nozzles in continuous casting of steel, Metall. Mater. Trans. B, 39(2008), No. 6, p. 870.

R. McDavid and B.G. Thomas, Flow and thermal behavior of the top surface flux/powder layers in continuous casting molds, Metall. Mater. Trans. B, 27(1996), No. 4, p. 672.

A. Hajari and M. Meratian, Surface turbulence in a physical model of a steel thin slab continuous caster, Int. J. Miner. Metall. Mater., 17(2010), No. 6, p. 697.

J. Sengupta, B.G. Thomas, H.J. Shin, G.G. Lee, and S.H. Kim, A new mechanism of hook formation during continuous casting of ultra-low-carbon steel slabs, Metall. Mater. Trans. A, 37(2006), No. 5, p. 1597.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51674069) and the National Key R & D Program of China (No. 2017YFC0805100).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fei, P., Min, Y., Liu, Cj. et al. Effect of continuous casting speed on mold surface flow and the related near-surface distribution of non-metallic inclusions. Int J Miner Metall Mater 26, 186–193 (2019). https://doi.org/10.1007/s12613-019-1723-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1723-y