Abstract

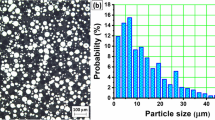

Ballpoint pen tip steel, a super free-cutting stainless steel, exhibits excellent corrosion resistance and good machining properties. In this study, inductively coupled plasma spectroscopy, metallographic microscopy, and scanning electron microscopy were used to determine the elemental contents in five ballpoint pen tips and their components, morphologies, and inclusion distributions. The results showed that the steels were all S–Pb–Te super free-cutting ferritic stainless steel. The free-cutting phases in the steels were mainly MnS, Pb, and small amounts of PbTe. MnS inclusions were in the form of chain distributions, and the aspect ratio of each size inclusion in the chain was small. The stress concentration effect could substantially reduce the cutting force when the material was machined. Some of the Pb was distributed evenly in the steel matrix as fine particles (1–2 μm), and the rest of the Pb was distributed at the middle or at both ends of the MnS inclusions. The Pb plays a role in lubrication and melting embrittlement, which substantially increases the cutting performance. PbTe was also usually distributed in the middle and at both ends of the MnS inclusions, and Te could convert the sulfides into spindles, thereby improving the cutting performance of the steel.

Similar content being viewed by others

References

P. Gao, K.M. Chen, Q.X. Dai, A.F. Meng, and T.F. Dai, Microstructure and cutting performance of new free-cutting stainless steels used for ball point pen, Mater. Mech. Eng., 34(2010), No. 9, p. 41.

L.S. Li, R. Zhu, H.J. Guo, J. Dong, and F. Li, Development of non-leaded free-cutting steel by adding tin, J. Univ. Sci. Technol. Beijing, 25(2003), No. 4, p. 312.

L.S. Li, R. Zhu, Y.H. Sun, H.J. Guo, H. Yin, and J. Dong, Form and distribution of inclusions and tin in free-cutting steel, J. Univ. Sci. Technol. Beijing, 26(2004), No. 5, p. 471.

Y.N. Wang, Y.P. Bao, M. Wang, and L.C. Zhang, Smelting process and machinability of BN-type free-cutting steel, J. Univ. Sci. Technol. Beijing, 35(2013), No. 7, p. 869.

Y.J. Xia, F.M. Wang, C.R. Li, J.L. Wang, and Z.Y. Wu, Study on the formation behavior of sulfides in free-cutting steel by unidirectional solidification, J. Univ. Sci. Technol. Beijing, 34(2012), No. 2, p. 118.

Y.N. Chen, Y.P. Bao, M. Wang, X.F. Cai, L.J. Wang, and L.H. Zhao, Superior machinability of steel enhanced with BN and MnS particles, Int. J. Miner. Metall. Mater., 23(2016), No. 3, p. 276.

G.A. Yan, Z. Qin, Z.H. Tian, Y.H. Sun, and K.K. Cai, Inclusion morphology control in medium-carbon calcium sulphur free-cutting steel, J. Univ. Sci. Technol. Beijing, 29(2007), No. 7, p. 685.

L.C. Zheng, A. Malfliet, P. Wollants, B. Blanpain, and M.X. Guo, Effect of surfactant Te on the formation of MnS inclusions in steel, Metal. Mater. Trans. B, 48(2017), No. 5, p. 2447.

Y.N. Wang, Y.P. Bao, and J. Yang, Effects of non-metallic inclusions on machinability of free-cutting steels investigated by nano-indentation measurements, Metall. Mater. Trans. A, 46(2015), No. 1, p. 281.

Y.N. Wang, J. Yang, and Y.P. Bao, Nanoindentation characterization of non-metallic inclusions in free cutting steel, J. Univ. Sci. Technol. Beijing, 36(2014), No. 7, p. 903.

X.Q. Xia, J.S. Zhang, and Y.M. Zou, An investigation on the machinability of newly developed low-carbon sulphurised free-cutting steels, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 230(2016), No. 9, p. 1592.

J.Y. Xu, Q.L. An, and M. Chen, Experimental study on high-speed turning of free-cutting steel AISI 12L14 using multi-layer coated carbide tools, Adv. Mater. Res., 500(2012), p. 3.

Y.N. Wang, J. Yang, and Y.P. Bao, Effects of non-metallic inclusions on machinability of free-cutting steels investigated by nano-indentation measurements, Metall. Mater. Trans. A, 46(2015), No. 1, p. 281.

S. Zhang, S.F. Zhang, J.S. Li, and L.Z. Wang, Morphology of MnS inclusions in Y15 high sulfur free-cutting steel by tellurium treatment, Iron Steel, 52(2017), No. 9, p. 27.

N. Matsui, T. Hasegawa, and J. Fujiwara, Effect of sulfide inclusion morphology on machinability and tool wear mechanism in low carbon free cutting steel, Int. J. Jpn. Soc. Precis. Eng., 77(2011), No. 3, p. 322.

D. Bhattacharya and D.T. Quinto, Mechanism of hot-shortness in leaded and tellurized free-machining steels, Metall. Trans. A., 11(1980), No. 6, p. 919.

M.A. Krishtal, A.A. Borgardt, and Y.D. Yashin, Effect of lead on the machinability of free-cutting steel, Met. Sci. Heat Treat., 19(1977), No. 3, p. 178.

P. Reynolds, V. Block, I. Essel, and F. Klocke, Alternatives to lead as a machinability enhancer in free cutting steels, Steel Res. Int., 78(2007), No. 12, p. 908.

Z. Li and D. Wu, Effect of free-cutting additives on machining characteristics of austenitic stainless steels, J. Mater. Sci. Technol., 26(2010), No. 9, p. 839.

N. Ånmark, A. Karasev, and P.G. Jönsson, The effect of different non-metallic inclusions on the machinability of steels, Materials, 8(2015), No. 2, p. 751.

D.Z. Li, S.Q. Gao, L.F. Zhang, Z.Y. Wang, and X.Q. Dong, Formation and behavior of telluride in free cutting steels, Iron Steel, 22(1987), No. 4, p. 38.

Acknowledgements

This work is supported by the National Nature Science Foundation of China (No. 51474142).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, Qk., Shen, P., Zhang, D. et al. Analysis on composition and inclusions of ballpoint pen tip steel. Int J Miner Metall Mater 25, 420–428 (2018). https://doi.org/10.1007/s12613-018-1587-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1587-6