Abstract

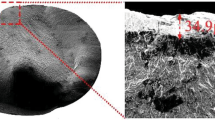

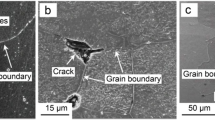

The ferrite decarburization behavior of 60Si2MnA spring steel wires for automotive suspensions, including the forming condition and the influence of heating time and cooling rate after hot rolling, was investigated comprehensively. Also, a control strategy during the reheating process and cooling process after rolling was put forward to protect against ferrite decarburization. The results show that ferrite decarburization, which has the strong temperature dependence due to phase transformation, is produced between 675 and 875°C. The maximum depth is found at 750°C. Heating time and cooling rate after rolling have an important influence on decarburization. Reasonable preheating temperature in the billet reheating process and austenitizing temperature in the heat-treatment process are suggested to protect against ferrite decarburization.

Similar content being viewed by others

References

Y. Prawoto, M. Ikeda, S.K. Manville, et al., Design and failure modes of automotive suspension springs, Eng. Failure Anal., 15(2008), p.1155.

R.X. Shi, C.F. Yao, W.J. Hui, et al., Effect of Si on behavior of oxidation and decarburization of medium carbon spring steels, Spec. Steel, 29(2008), No.3, p.19.

K. Adamaszek, P. Bro, and J. Kucera, Decarburization and hardness changes in carbon steels caused by high-temperature surface oxidation in ambient air, Defect Diffus. Forum, 194–199(2001), p.1701.

T. Nakano, T. Sakakibara, M. Wakita, et al., Effect of alloying elements and surface treatment on corrosion fatigue strength of high-strength suspension coil springs, JSAE Rev., 22(2001), p.337.

Y. Akiniwa, S. Stanzl-Tschegg, H. Mayer, et al., Fatigue strength of spring steel under axial and torsional loading in the very high cycle regime, Int. J. Fatigue, 30(2008), p.2057.

D.H. Rowland and C. Upthegrove, Grain-size and its influence on surface decarburization of steel, Trans. Am. Soc. Met., 24(1936), p.96.

J.L. Snoek, On the decarburization of steel and related questions, Physica, 8(1941), No.7, p.734.

W.A. Pennington, A mechanism of the surface decarburization of steel, Trans. Am. Soc. Met., 37(1946), p.48.

D.J. Li, D. Anghelina, D. Burzic, et al., Investigation of decarburization in spring steel production process: Part I. Experiments, Steel Res. Int., 80(2009), No.4, p.298.

J. Baud, A. Ferrier, J. Manenc, et al., The oxidation and decarburizing of Fe-C alloys in air and the influence of relative humidity, Oxid. Met., 9(1975), No.1, p.69.

R.Y. Chen and W.Y.D. Yuen, Review of the high-temperature oxidation of iron and carbon steels in air or oxygen, Oxid. Met., 59(2003), No.5–6, p.433.

J. Kucera and K. Adamaszek, The initial stage of oxidation of iron and steels heated at high temperatures in ambient air, Kovové Mater., 39(2001), No.5, p.289.

A.M. Medvedev, E.A. Mazurenko, S.L. Vrochinskii, et al., Protection of steels and alloys from oxidation and decarburization during heat treatment in muffle and bell furnaces, Met. Sci. Heat Treat., 45(2003), No.7–8, p.270.

Y. Prawoto, N. Sato, I. Otani, et al., Carbon restoration for decarburized layer in spring steel, J. Mater. Eng. Perform., 13(2004), No.5, p.636.

Y.H. Nie, S.H. Fu, W.J. Hui, et al., Effect of boron on decarburization sensitivity of high strength spring steel, J. Iron Steel Res., 17(2005), No.4, p.45.

M.T. Ma, Z.G. Li, and X.Y. Lu, Effect of vanadium on decarburization sensitivity of spring steel 35SiMnB, Spec. Steel, 22(2001), No.5, p.9.

H. Ding, Y.Z. Liu, and L.F. Zhang, Effects of processing parameters on phase transition rules of high speed rolled wire of 60Si2MnA steel, J. Univ. Sci. Technol. Beijing (in Chinese), 23(2001), No.1, p.28.

J.H. Ai, T.C. Zhan, H.J. Gao, et al., Effects of controlled rolling and cooling on the precipitated pearlite of 60Si2MnA spring steel wire rods, J. Univ. Sci. Technol. Beijing (in Chinese), 24(2002), No.5, p.503.

G. Parrish, Carburizing: Microstructures and Properties, ASM International, Materials Park, 1999.

G.X. Hu and X. Cai, Fundamentals of Materials Science, Shanghai Jiaotong University Press, Shanghai, 2000, p.136.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Cl., Liu, Yz., Zhou, Ly. et al. Forming condition and control strategy of ferrite decarburization in 60Si2MnA spring steel wires for automotive suspensions. Int J Miner Metall Mater 19, 116–121 (2012). https://doi.org/10.1007/s12613-012-0525-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0525-2